Method for determining colorant in cigarette package material

A packaging material and measurement method technology, applied in the field of determination of colorants in cigarette packaging materials, to achieve the effects of quantitative accuracy, good reproducibility, and fast analysis speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] a. Preparation of extract: methanol, 10% ammonia water and water are prepared into a mixed solution in a volume ratio of 1:1:8 as the extract;

[0016] b. Extraction of colorants in cigarette packaging materials: crush the samples of cigarette packaging materials into 1cm 2 For left and right debris, after mixing evenly, accurately weigh 0.5±0.1mg and place it in a 25mL conical flask, then accurately add 10mL of the above extract, shake and extract for 30 minutes and then let it stand;

[0017] c. After standing for 5 minutes, pipette 2-3ml of the supernatant to pass through a 0.45μm organic phase filter, and analyze the filtrate by liquid chromatography.

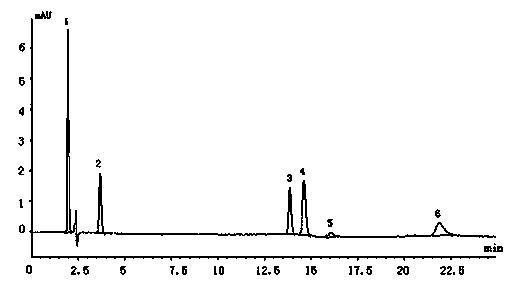

[0018] Chromatographic analysis conditions: the chromatographic column adopts Agilent Zorbax SB-C 18 (250 mm×4.6mm, 5μm); detector: UV; column temperature: 30°C; detection wavelength: variable wavelength method, the wavelength of each analyte is shown in Table 3; flow rate: 1.0mL / min; injection volume: 10 μL; Qual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com