Heat-resistant and oil-resistant butadiene-acrylonitrile rubber material as well as preparation method and application thereof

A technology of nitrile rubber and rubber compound, applied in the field of rubber sealing, can solve the problems of no compression set performance, damaged oil resistance, no given, etc., to achieve excellent processing safety, excellent thermal stability, and improved coke. The effect of burning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

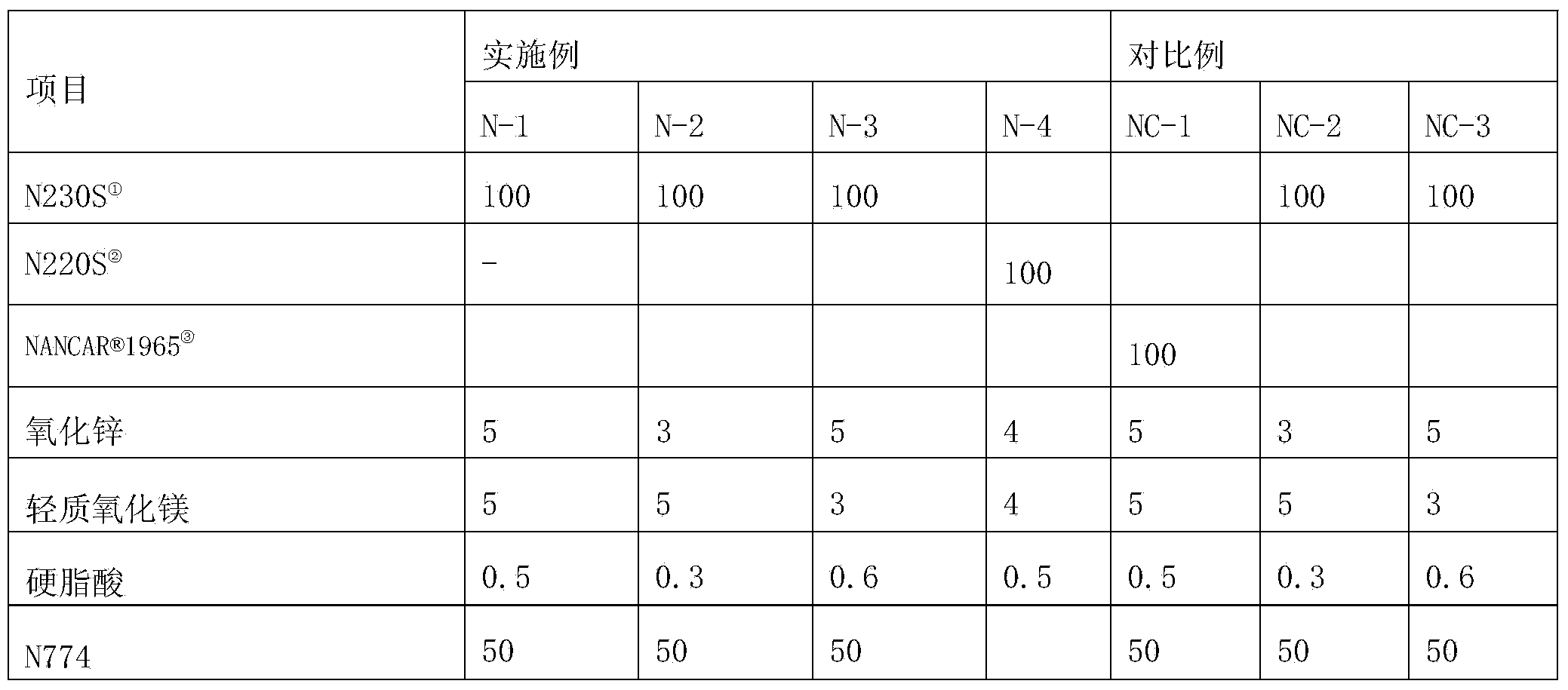

[0045] Embodiment and comparative example are prepared according to the following methods:

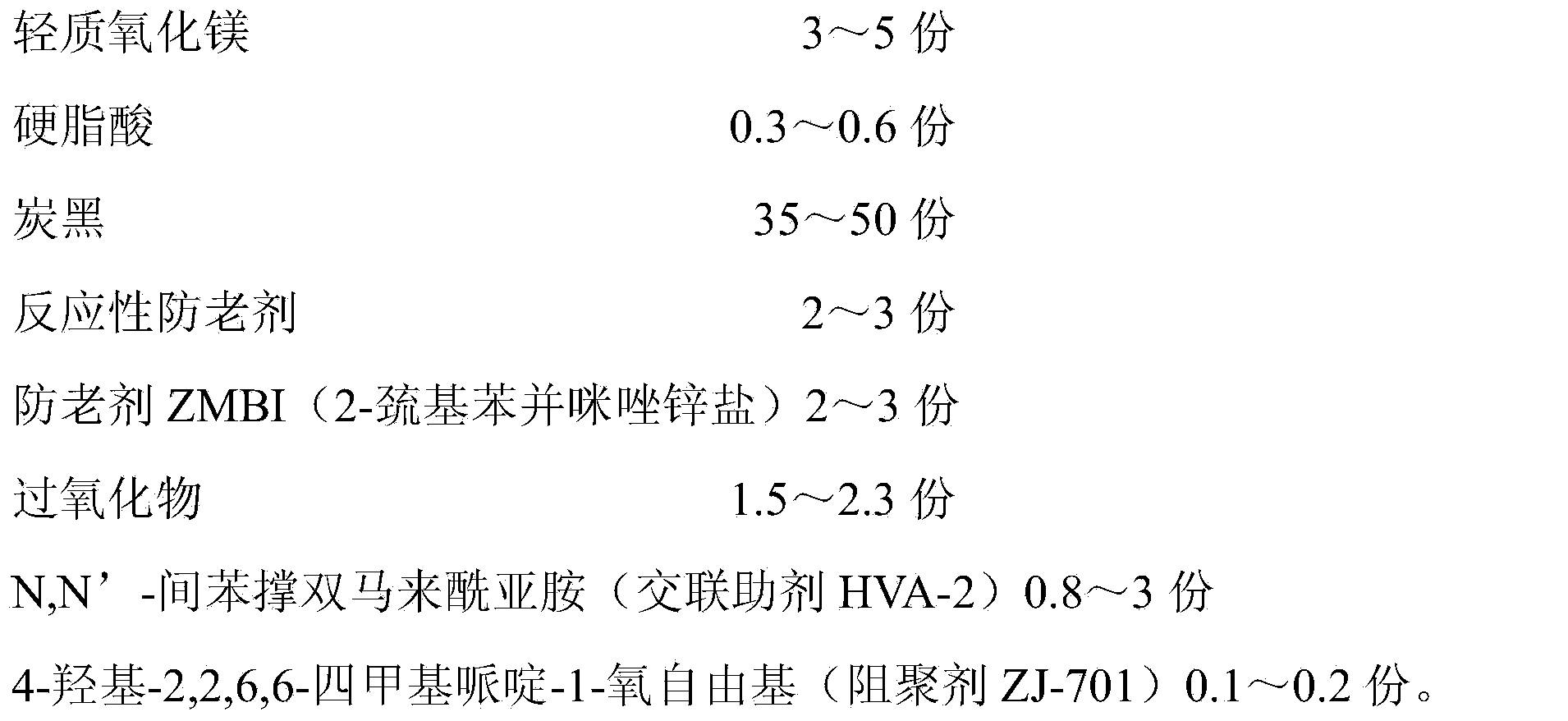

[0046] (1) The preparation method of rubber compound (recipe is as shown in Table 1)

[0047] ① Add nitrile rubber to the open mill, adjust the roller distance, add zinc oxide, light magnesium oxide, stearic acid, reactive anti-aging agent and 2-mercaptobenzimidazole zinc salt in sequence after the rubber material is covered with rollers, and mix for 2~ 3 minutes until the powder is completely mixed in;

[0048] ② Add carbon black and knead for 6-8 minutes until the carbon black is completely mixed in;

[0049] ③Add peroxide and co-crosslinking agent (N,N'-m-phenylene bismaleimide and 4-hydroxy-2,2,6,6-tetramethylpiperidine-1-oxyl radical) , kneading for 1 to 2 minutes until the powder is completely mixed in, then thin pass 3 times, take off the sheet, cool, and park to obtain a heat-resistant and oil-resistant nitrile rubber compound.

[0050] (2) Preparation of test pieces and sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| compression set | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com