Graphene modified epoxy resin material and preparation method thereof

A technology of graphene modification and epoxy resin, which is applied in the field of epoxy resin materials, can solve the problems of high brittleness and easy cracks, reduce shrinkage, improve structural stability, improve bonding strength and heat resistance stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a kind of preparation method of graphene modified epoxy resin material, comprises the following steps:

[0024] S1: Add graphene into nitric acid / sulfuric acid solution with a volume ratio of 1:3, ultrasonically disperse it evenly, and then reflux at 70-80°C for 2 hours to obtain carboxylated graphene;

[0025] S2: Adjust the silane coupling agent to acidity, then add it to absolute ethanol, add the carboxylated graphene for ultrasonic dispersion, react at 55-60°C for 6 hours, wash with acetone, filter, and dry to obtain graphene-grafted silane coupling agent;

[0026] S3: Add the carboxylated graphene, sodium dodecylbenzenesulfonate and ethanol in the container, ultrasonically disperse for 30 minutes, then add epoxy resin and mix evenly, continue ultrasonicating for 30 minutes, stir at 70-80°C to make the ethanol completely Volatilize to obtain graphene-doped epoxy resin;

[0027] S4: Transfer the graphene-doped epoxy resin to a stirred tank, a...

Embodiment 1

[0033] Embodiment 1: according to the above steps, the parts by weight of each component are 10 parts of graphene doped epoxy resin, 30 parts of inorganic nano fillers, 3 parts of curing agent and 1 part of modified silane coupling agent; wherein graphene doped The mass fraction of carboxylated graphene in the preparation of epoxy resin is 1% of epoxy resin, and the mass fraction of carboxylated graphene in the preparation of graphene-grafted silane coupling agent is 0.05% of silane coupling agent.

Embodiment 2

[0034] Embodiment 2: according to the above steps, the parts by weight of each component are 12 parts of graphene doped epoxy resin, 33 parts of inorganic nano fillers, 3 parts of curing agent and 1 part of modified silane coupling agent; wherein graphene doped The mass fraction of carboxylated graphene in the preparation of epoxy resin is 2% of epoxy resin, and the mass fraction of carboxylated graphene in the preparation of graphene-grafted silane coupling agent is 0.07% of silane coupling agent.

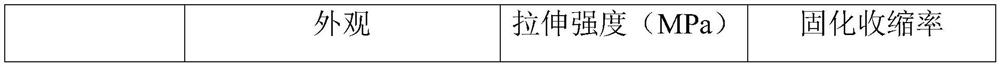

PUM

| Property | Measurement | Unit |

|---|---|---|

| cure shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com