High-temperature-resistant medical gloves

A technology of high temperature resistance and gloves, used in gloves, applications, clothing, etc., can solve the problems of low softening deformation temperature, environmental white pollution, environmental pollution, etc., to achieve good high temperature resistance, reduce environmental pollution, and improve durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

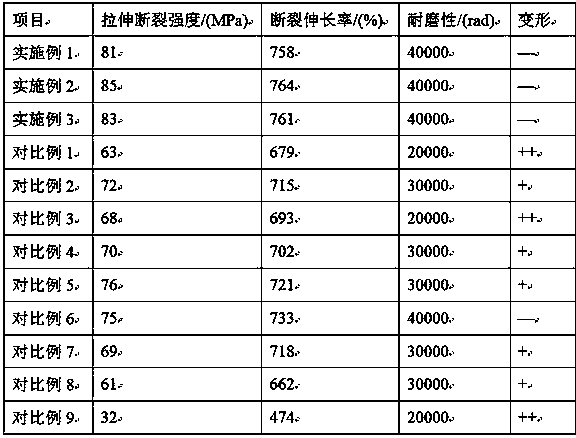

Examples

Embodiment 1

[0019] A high-temperature-resistant medical glove is made of the following raw materials in parts by weight: modified low-density polyethylene 52, epoxy resin 33, polyvinyl alcohol 27, sodium polyacrylate 6, nano-titanium dioxide 7, and nano-eggshell 11.

[0020] For the modified low-density polyethylene, heat the low-density polyethylene to 130°C, fully melt it, add 20% by weight of low-density polyethylene and a sodium chloride solution with a concentration of 4% by mass, and use 52r / min Stir at high speed for 20 minutes, then add 1.6% nano-silica of low-density polyethylene by weight, continue to keep warm and stir for 15 minutes, and cool naturally to improve the film-forming property and high-temperature resistance of low-density polyethylene to obtain modified low-density polyethylene.

[0021] Described polyvinyl alcohol is medical grade polyvinyl alcohol.

[0022] For the nano-eggshell, first wash the eggshell and crush it to 25nm, then add an acetic acid solution with...

Embodiment 2

[0031] A high-temperature-resistant medical glove is made of the following raw materials in parts by weight: modified low-density polyethylene 53, epoxy resin 34, polyvinyl alcohol 28, sodium polyacrylate 7, nano-titanium dioxide 8, and nano-eggshell 12.

[0032] For the modified low-density polyethylene, the low-density polyethylene is heated to 135°C, fully melted, and a sodium chloride solution with a mass percentage concentration of 23% of the weight of the low-density polyethylene and a concentration of 4.5% is added, at a rate of 53r / min Stir at high speed for 23 minutes, then add 1.7% nano-silica by weight of low-density polyethylene, continue to keep warm and stir for 18 minutes, and cool naturally to improve the film-forming property and high-temperature resistance of low-density polyethylene to obtain modified low-density polyethylene.

[0033] Described polyvinyl alcohol is medical grade polyvinyl alcohol.

[0034] For the nano-eggshell, first wash the eggshell, cru...

Embodiment 3

[0043] A high-temperature-resistant medical glove is made of the following raw materials in parts by weight: modified low-density polyethylene 54, epoxy resin 35, polyvinyl alcohol 29, sodium polyacrylate 8, nano-titanium dioxide 9, and nano-eggshell 13.

[0044] For the modified low-density polyethylene, heat the low-density polyethylene to 140°C, fully melt it, add 25% of the weight of the low-density polyethylene into a sodium chloride solution with a concentration of 5% by mass, and use 54r / min Stir at high speed for 25 minutes, then add 1.8% nano-silica of low-density polyethylene by weight, continue to keep warm and stir for 20 minutes, and cool naturally to improve the film-forming property and high-temperature resistance of low-density polyethylene to obtain modified low-density polyethylene.

[0045] Described polyvinyl alcohol is medical grade polyvinyl alcohol.

[0046] For the nano-eggshell, first wash the eggshell, crush it to 30nm, then add an acetic acid solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com