Dendritic polymer, dendritic polymer monomer, and preparation methods and application of two

A dendritic, polymer technology, used in chemical instruments and methods, sulfonate preparation, drilling compositions, etc., can solve problems such as decreased viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

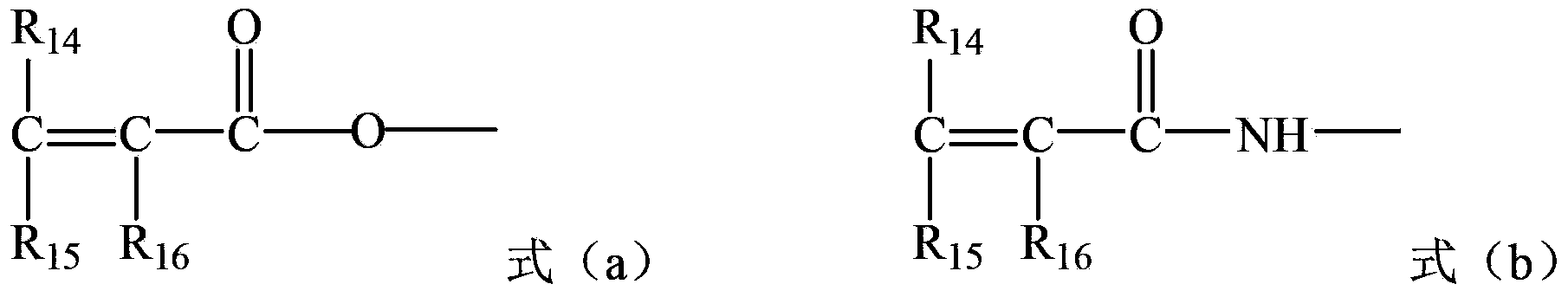

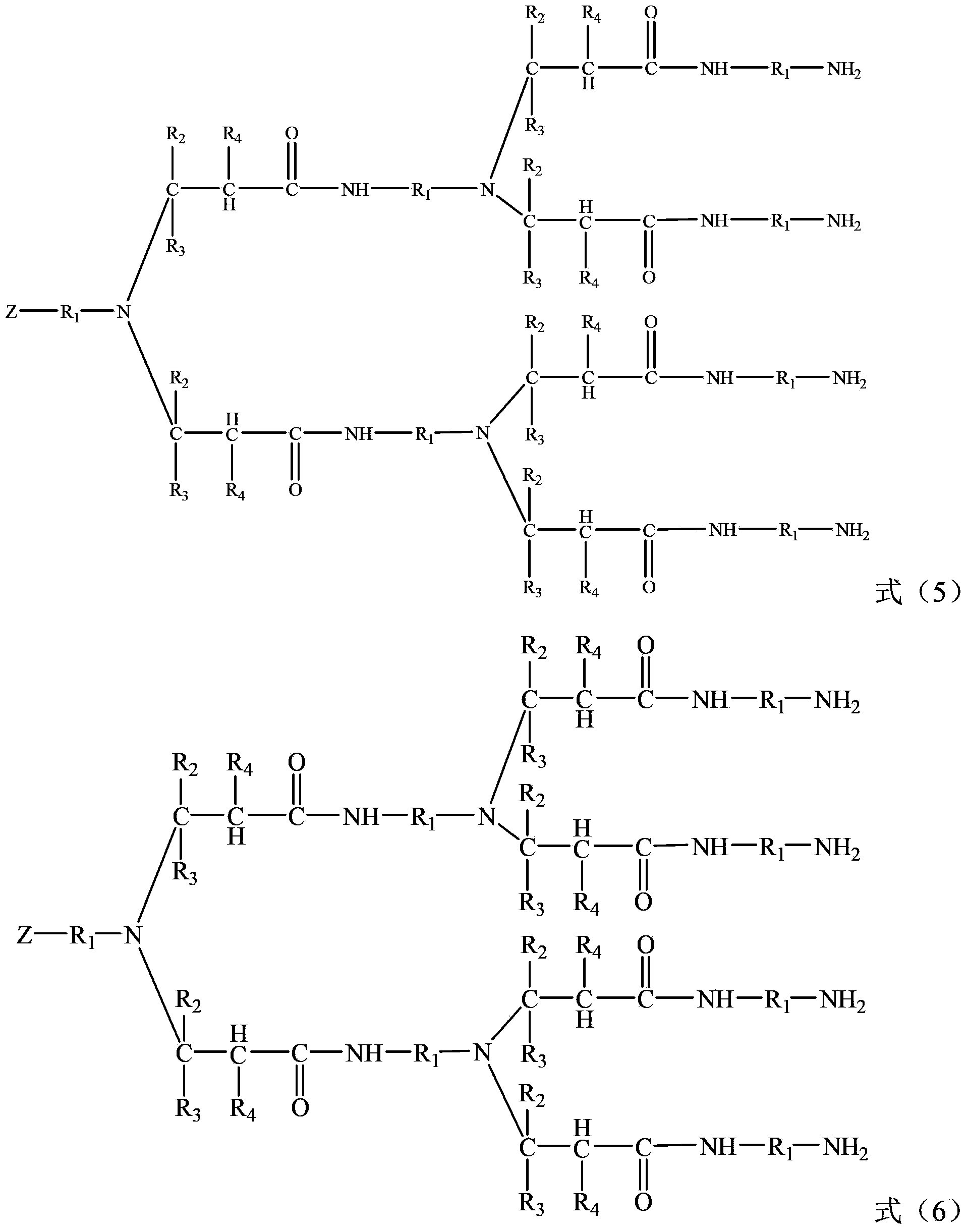

[0052] According to the preparation method of a dendritic polymer provided by the present invention, when the dendritic polymer has the structure shown in the above formula (III) and / or formula (IV), the method includes the following steps:

[0053] (1) Preparation of intermediates having the structures shown in the following formula (5) and / or formula (6),

[0054]

[0055]

[0056] In formula (5) and formula (6), R 1 Represents an alkylene group with 1-5 carbon atoms, R 2 -R 4 The same or different, each independently being H or an alkyl group with 1-5 carbon atoms, and n R in the structure shown in formula (I) 1 -R 4 are independently the same or different;

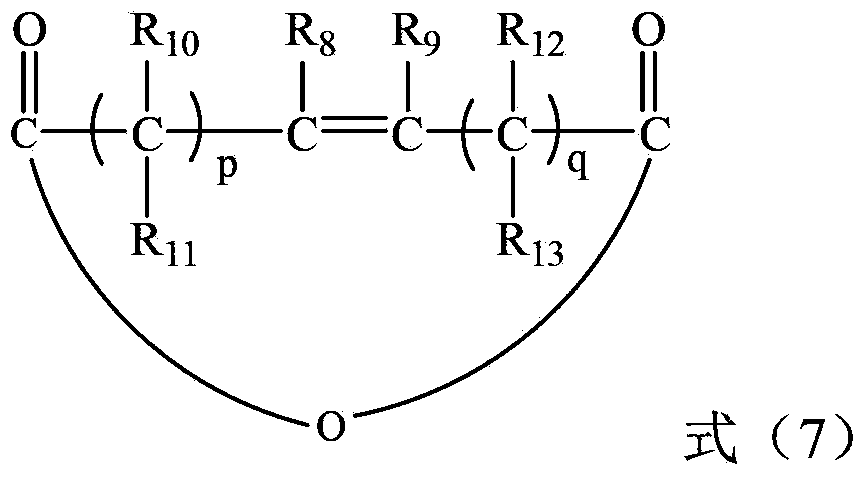

[0057] (2) Under the conditions of nucleophilic addition reaction, the intermediate is contacted with an unsaturated acid anhydride represented by the following formula (7) to form a carboxylic acid amide containing an unsaturated bond,

[0058]

[0059] In formula (7), R 8 -R 13 The same or different, ...

Embodiment approach

[0092] According to a preferred embodiment of the present invention, the preparation method of the dendritic polymer monomer may include the following steps: adding the above-mentioned dendritic polymer, organic solvent and acid-binding agent into a reaction flask equipped with a cooling device, cooling to 5°C, and then slowly add the unsaturated acid halide (the temperature during the addition should not exceed 15°C). After adding the unsaturated acid halide, react at about 10°C for 0.5-8h. The reactant was left standing, the organic phase was separated, neutralized and washed several times with saturated sodium bicarbonate solution, dried with anhydrous sodium sulfate, and the organic solvent was evaporated to obtain the crude product, which was further purified to obtain the polymer grade The product is the dendrimer monomer.

[0093] The unsaturated acid halide can be unsaturated acid chloride and / or unsaturated acid bromide, the number of carbon atoms of the unsaturated a...

preparation example 1

[0101] Synthesis of intermediates.

[0102] First synthesize the intermediate according to the conventional method:

[0103] (I) Add methyl acrylate, ethanolamine and methanol in the reaction kettle according to the molar ratio of 1:0.5:15, at room temperature and through N 2 Stirring for 30 minutes under normal conditions, then raising the temperature to 35°C for 4 hours, and then distilling under reduced pressure to remove methanol to obtain a product with the structure shown in formula (5a).

[0104]

[0105] (II) Add the product with the structure shown in formula (5a) and methanol into the reaction kettle according to the weight ratio of 1:3, and add ethylenediamine (the mole of the product with the structure shown in formula (5a) The ratio is 1:1.05) after reaction for 24h, and then distilled under reduced pressure to remove methanol to obtain the intermediate product shown in the structure of formula (5b).

[0106]

[0107] (III) Add the intermediate product of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com