Preparation method and application of carbon coated carbon nitride/silicon-silicon nitride/silicon dioxide composite material

A technology of carbon-coated carbon nitride and silicon dioxide, which is applied in the field of nanomaterials to achieve the effects of less impurity content, high capacity retention rate, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] 10 grams of SiO and 10 grams of artificial graphite FSN-4 were added to 20 milliliters of ethanol, and ball milled with agate balls at 400 rpm for 21 hours in a QM-2SP12 ball mill in Nanjing University Instrument Factory. Then take out and dry the grinding balls in a self-made glove box under argon protection, add a mixed solution of 10 grams of furfuryl alcohol, 25 grams of absolute ethanol, and 0.75 grams of water, and stir evenly. Add a mixed solution of 0.7 gram of water and 0.3 gram of hydrochloric acid, stir evenly, and let it stand for 12 hours, so that the furfuryl alcohol is fully polymerized.

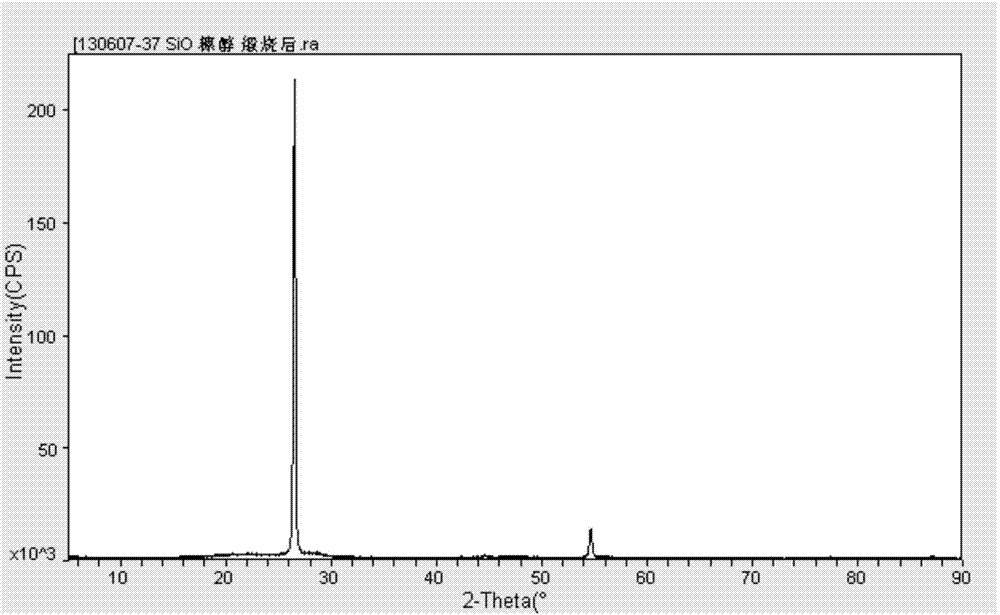

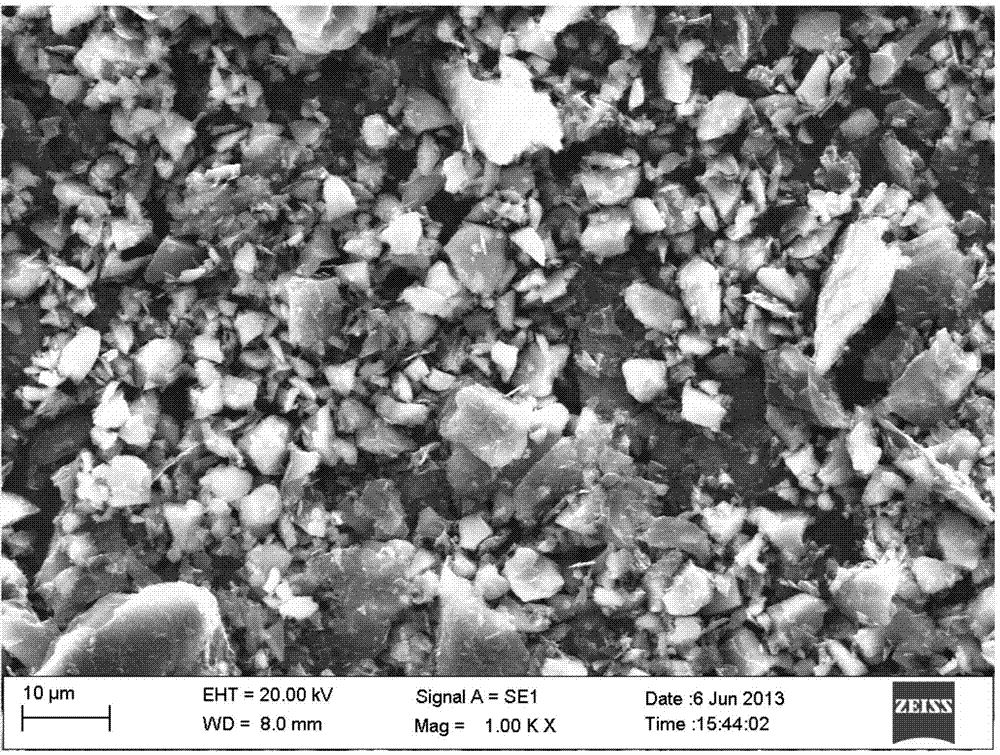

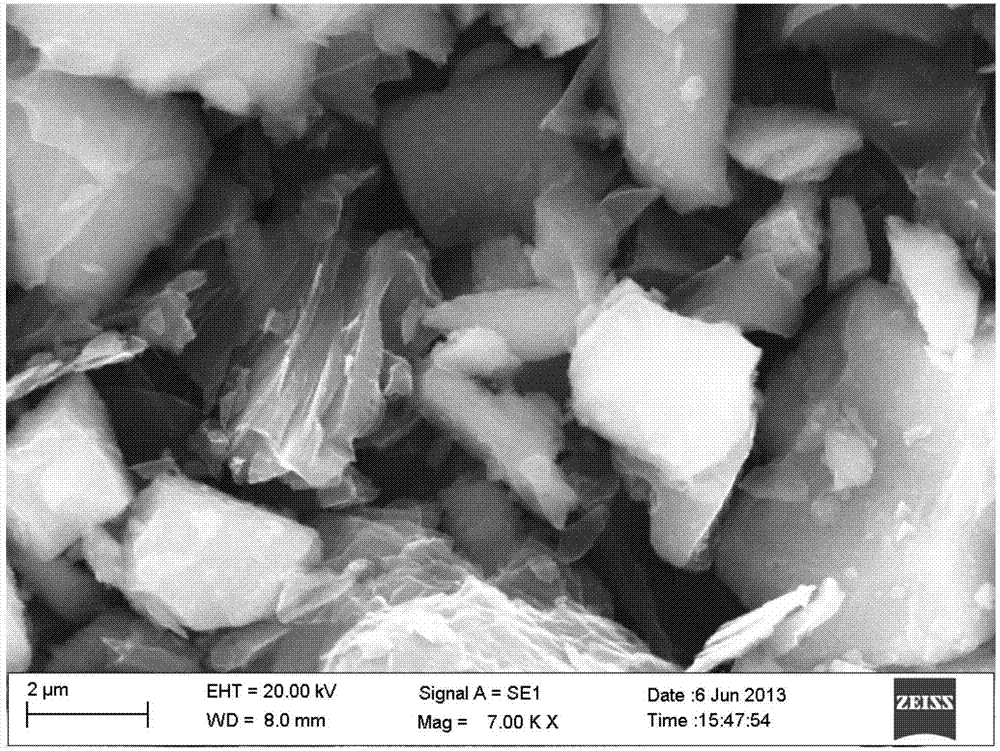

[0066] The mixture after the polymerization reaction was transferred to an alumina crucible, placed in a high-temperature atmosphere electric furnace of Shanghai Jiugong Electric Co., Ltd., vacuumed, and 99.9% argon protective gas was passed, and then the temperature was raised to 1000°C at a rate of 5°C / min, and Keeping at this temperature for 3 hours, silicon oxide un...

Embodiment 2

[0068] Embodiment 2 Ionic liquid C 10 h 15 N 5

[0069] The preparation method of the carbon-coated silicon / silicon dioxide nanocomposite is the same as in Example 1.

[0070] Weigh 3 grams of carbon-coated silicon / silica nanocomposites and 1.5 grams of colorless ionic liquid 1-butyl-3-methylimidazole dinitrile amine salt (C 10 h 15 N 5 ), grind it evenly in an agate mortar, put it into an alumina crucible, put it into a high-temperature atmosphere electric furnace of Shanghai Jiugong Electric Co., Ltd., evacuate, pass 99.9% argon protective gas, and then heat up to 750°C, and kept at this temperature for 1 hour, after natural cooling, stop feeding argon.

[0071] The calcined product is brown-black carbon-coated carbon nitride / silicon-silicon nitride / silicon dioxide nanocomposite powder solid.

example 3

[0072] Example 3 Ionic Liquid C 11 h 14 N 4

[0073] The preparation method of the carbon-coated silicon / silicon dioxide nanocomposite is the same as in Example 1.

[0074] Weigh 3 grams of carbon-coated silicon / silica nanocomposites and 1.52 grams of brown liquid ionic liquid 1-butylpyridine dinitrile amine salt (C 11 h 14 N 4 ). The nitriding reaction environment and conditions are the same as in Example 2.

[0075] The calcined product is brown-black carbon-coated carbon nitride / silicon-silicon nitride / silicon dioxide nanocomposite powder solid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com