Preparation methods of nanopore-arrayed anodic alumina membrane and nanopore-arrayed anodic alumina microchannel plate

A technology of anodized aluminum and nanohole arrays, which is applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problems of increasing the area of the microchannel plate and the difficulty of reducing the channel aperture, and achieve high Spatial resolution, the effect of high spatial resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

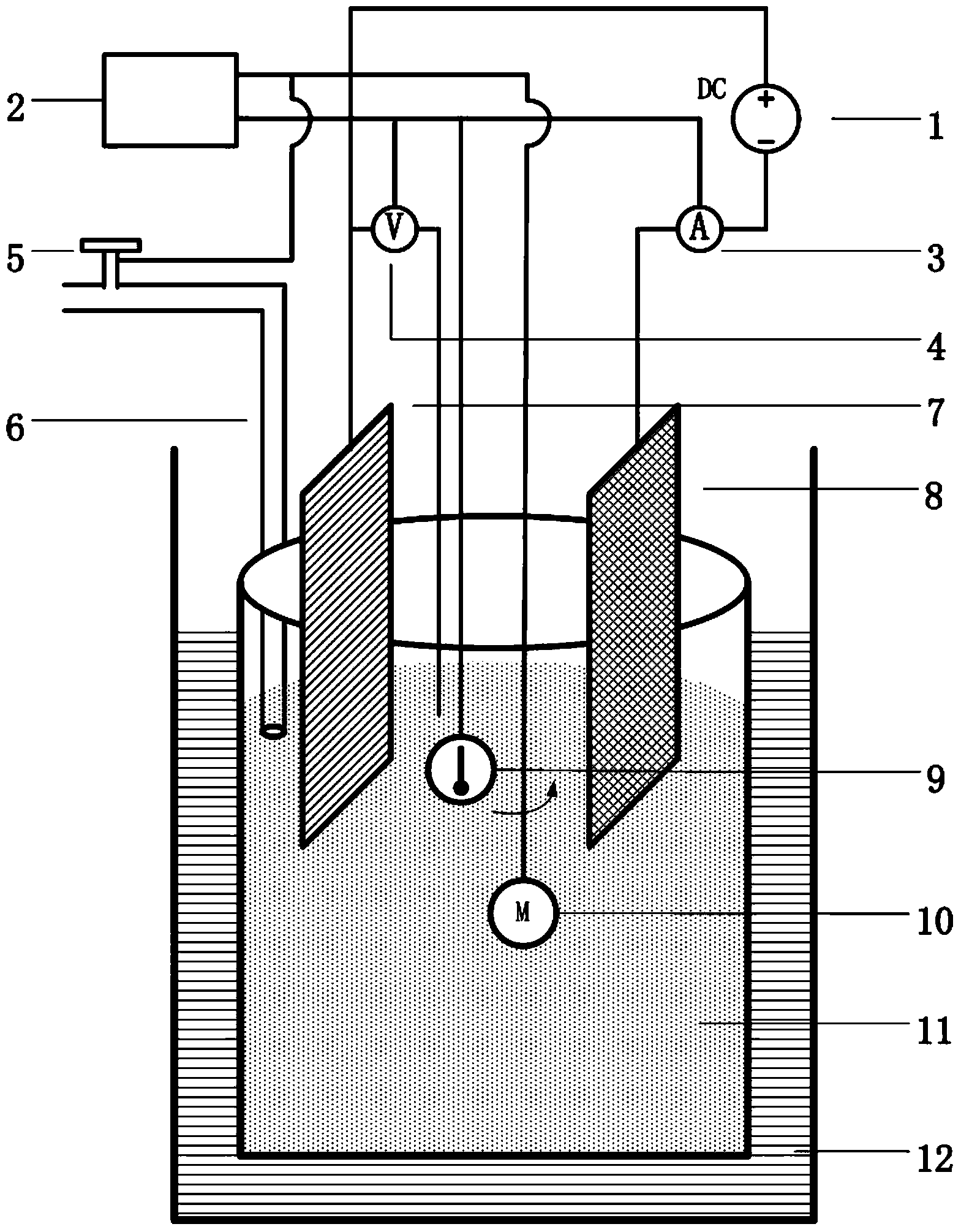

Method used

Image

Examples

Embodiment Construction

[0080] Anodized aluminum can withstand high temperatures up to 2000°C in a vacuum environment, so that the photocathode material can be directly deposited on the input end of the microchannel plate under high temperature conditions. Therefore, the selection of photocathode materials is increased, thereby broadening the detection response wavelength range of the microchannel plate, and at the same time, some materials with high secondary electron emission coefficients can be selected to be deposited on the input end, such as diamond. This can greatly increase the electron yield of the first particle collision, and for devices that need to be used under ultra-high vacuum, the increase in the baking temperature is conducive to enhancing the use of vacuum and signal-to-noise ratio, thereby effectively improving the reliability and reliability of optoelectronic devices. service life.

[0081] The processing technology of the microchannel plate based on the nano-hole array anodized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com