Polyvinylidene fluoride (PVDF) agricultural plastic colored mulching film and manufacturing method thereof

A technology of polyvinylidene fluoride and vinylidene fluoride, which is applied to the manufacture of the above-mentioned polyvinylidene fluoride agricultural plastic colored mulch film, and the field of polyvinylidene fluoride agricultural plastic colored mulch film, which can solve the problem that it is difficult to exert benefits and the recycling cost is high , economic gains outweigh the losses, etc., to achieve excellent mechanical properties and weather resistance, increase yield and quality, and prevent insect fertilizer loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

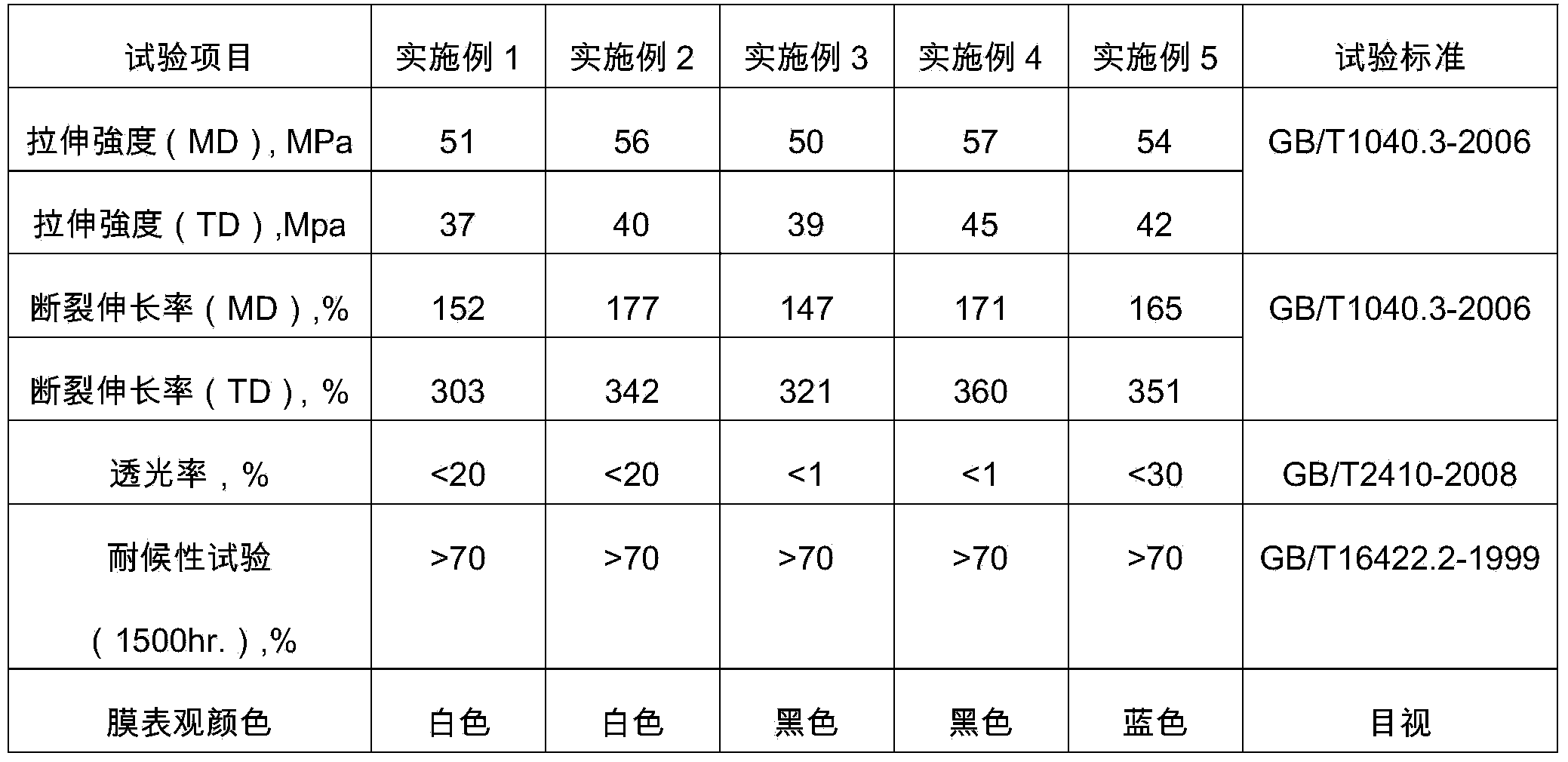

Examples

Embodiment 1

[0023] Contains the following mass percentage components: PVDF resin (VDF homopolymer, melt flow index 8 ~ 15g / 10min (230 ℃, 5Kg), obtained from domestic Sanaifu company) 54%, Plexiglas 7N (polymethacrylate Ester resin, melt flow index is 6g / 10min (230 ℃, 3.8Kg) obtains from Evonik Rohm company) 32%, R-960 (is the nanoscale rutile titanium dioxide, average particle size 500nm, the surface has been trioxide Aluminum and silica treatment, obtained from DuPont Company) 10%, composite light stabilizer (composition of UV absorber Tinuvin 1577, Tinuvin 327 and hindered amine Tinuvin 770, obtained from Ciba Refining Company) 2.6%, Irganox B 215 (composition of antioxidants Irgafos168 and Irganox1010, available from Ciba Fine Chemicals) 1.2%, dispersant EBS (N,N,-ethylenebisstearamide) 0.2%.

[0024] The above components were pre-dried and added to a high-speed mixer, stirred at a high speed of 90°C for 30 minutes, and then cooled to 45°C to obtain a special dry blend.

[0025] Extru...

Embodiment 2

[0028]Contains the following mass percentage components: PVDF resin (VDF homopolymer, melt flow index 8 ~ 15g / 10min (230 ℃, 5Kg), obtained from domestic Sanaifu company) 54%, Plexiglas 7N (polymethacrylate Ester resin, melt flow index is 6g / 10min (230 ℃, 3.8Kg) obtained from Evonik Rohm company) 20%, D320 (containing acrylate impact modifier: shell is PMMA, core is butyl acrylate / butadiene copolymer, obtained from Arkema company) 12%, R-960 (for nanoscale rutile titanium dioxide, average particle size 500nm, the surface has been treated with aluminum oxide and silicon dioxide, obtained from DuPont (DuPont) company ) 10%, composite light stabilizer (composition of UV absorber Tinuvin 1577, Tinuvin P and hindered amine Tinuvin 770, obtained from Ciba Refining Company) 2.6%, Irganox B 215 (composition of antioxidant Irgafos168 and Irganox1010, from Ciba Chemicals) 1.2%, dispersant EBS (N,N,-ethylenebisstearamide) 0.2%.

[0029] The above components were pre-dried and added to a...

Embodiment 3

[0033] Contains the following mass percentage components: PVDF resin (VDF homopolymer, melt flow index 8 ~ 15g / 10min (230 ℃, 5Kg), obtained from domestic Sanaifu company) 58%, Altuglas BS 580 (methyl methacrylate Copolymer of ester and methyl acrylate, the melt flow index is 4.5g / 10min (230 ℃, 3.8Kg) obtained from Arkema company) 35%, R-960 (for nano-scale rutile titanium dioxide, the average particle size is 500nm, the surface has been Aluminum oxide and silica treatment, obtained from DuPont Company) 0.1%, R330R (carbon black obtained from Cabot Company) 2.9%, composite light stabilizer (UV absorber Tinuvin 1577, Tinuvin 327 and hindered amine Tinuvin 770 Composition obtained from Ciba Chemical Company) 2.6%, Irganox B 215 (composition of antioxidant Irgafos168 and Irganox1010 obtained from Ciba Chemical Company) 1.2%, dispersant EBS (N,N,-ethylene bis stearamide) 0.2%.

[0034] The above components were pre-dried and added to a high-speed mixer, stirred at a high speed of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com