Catalyst and preparation method and application of catalyst

A technology of catalyst and alloy catalyst, which is applied in the field of chemical industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] (1) Catalyst preparation. Use Ti, Zr, Co, La elements with a purity of 99.5% or more, according to Ti 60 Zr 20 co 15 La 5 Atomic ratio composition weighs a certain amount of metal elements, and melts them into alloys in a vacuum electric arc furnace, using argon protection during melting. The obtained alloy molecular formula is Ti 60 Zr 20 co 15 La 5 . The obtained alloy is mechanically pulverized into particles of about 100-200 mesh as a catalyst for future use.

[0095] (2) Catalyzed oxidation reaction of cyclohexane. The reaction was carried out in a 600ml reactor, and the weight ratio of the catalyst to cyclohexane was 1:800. After feeding, the autoclave was heated to 140°C, filled with air to a pressure of 1.5MPa, and the reaction time was 300min, with constant stirring .

[0096] (3) Separation of reactants. After the reaction is finished, liquid phase and solid phase are centrifuged to obtain liquid phase product A and solid phase product B. The soli...

Embodiment 2-34

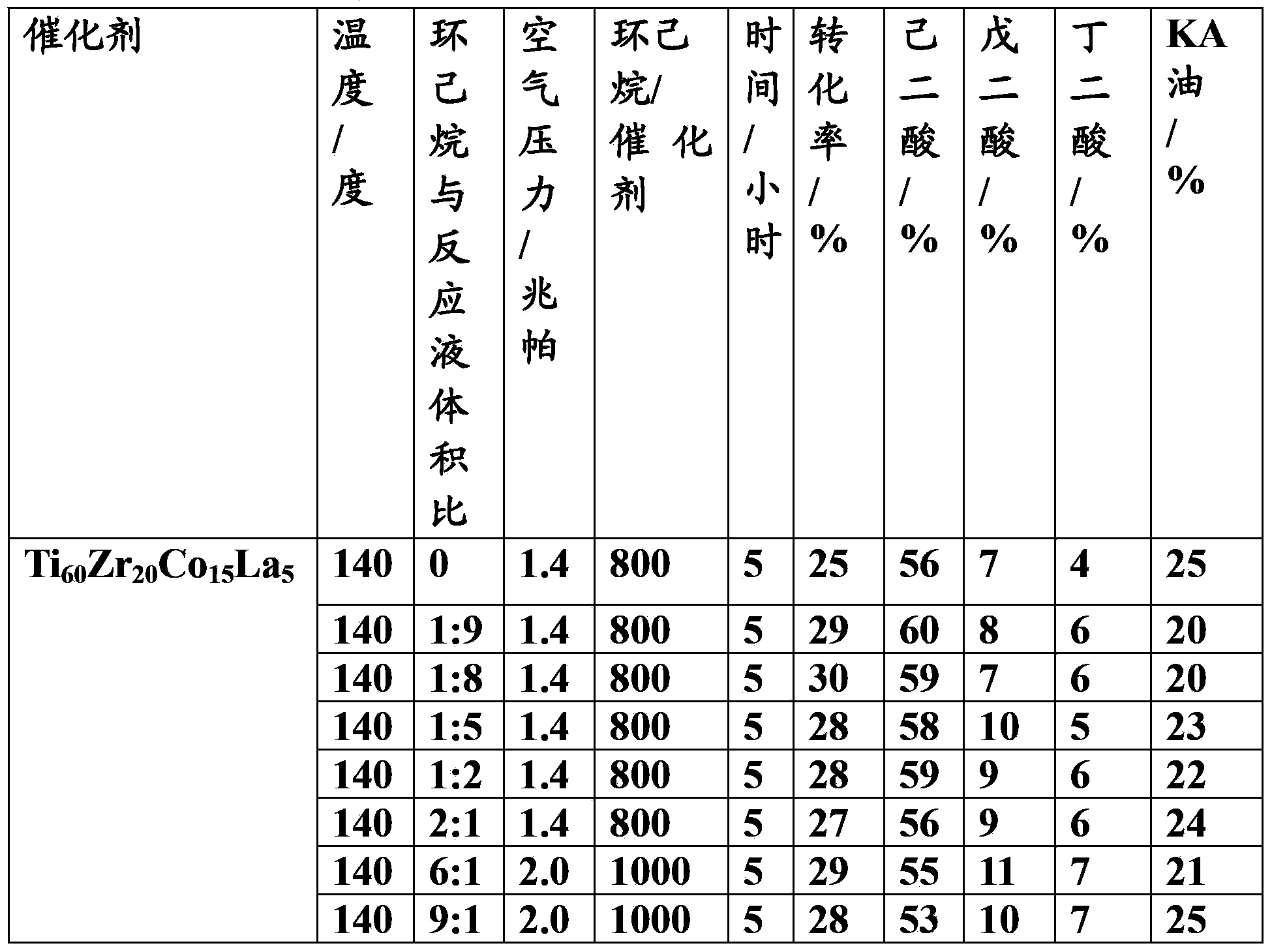

[0110] The preparation method of the catalyst is the same as in Example 1. Catalysts with different compositions are prepared, and the implementation results of the catalyzed cyclohexane oxidation reaction are shown in Table 2. Wherein the method for product analysis is with embodiment 1.

Embodiment 8

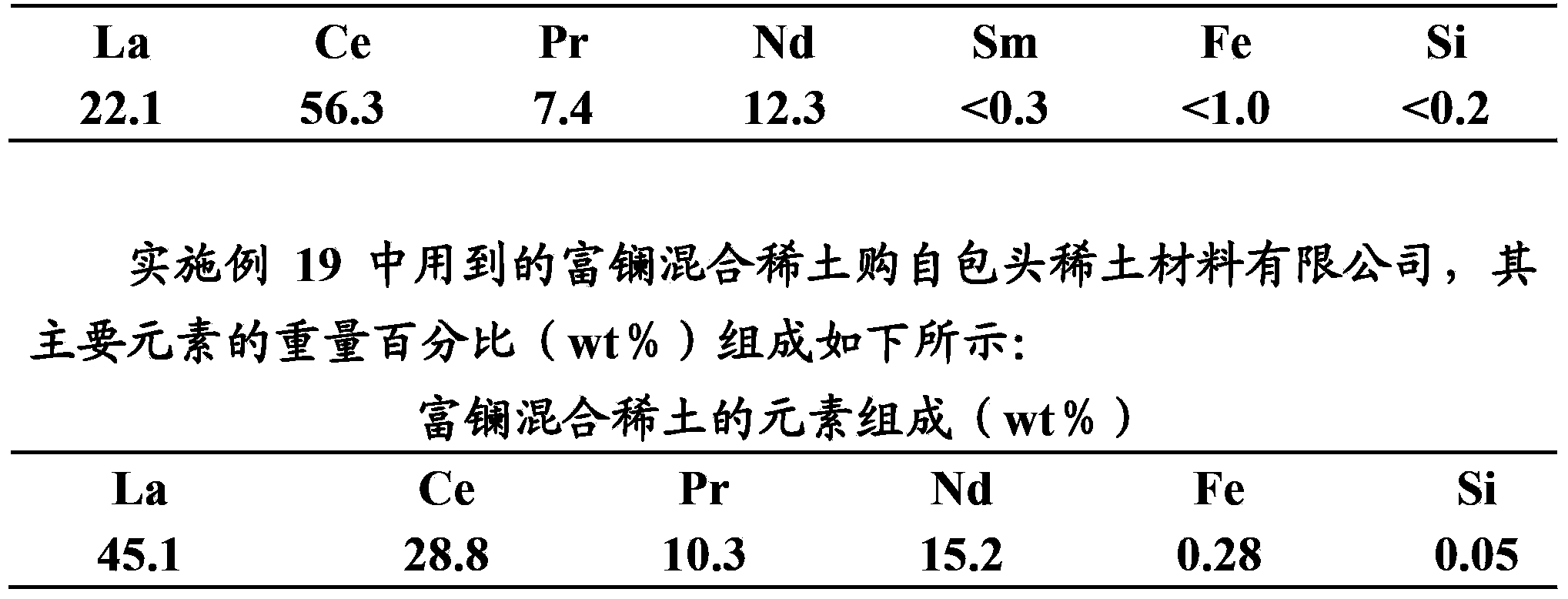

[0112] The cerium-rich mixed rare earth used in Example 8 was purchased from Beijing Haoyun Jinneng Technology Co., Ltd., and the weight percentage (wt%) composition of its main elements is as follows:

[0113] Elemental composition of cerium-rich mischmetal (wt%)

[0114]

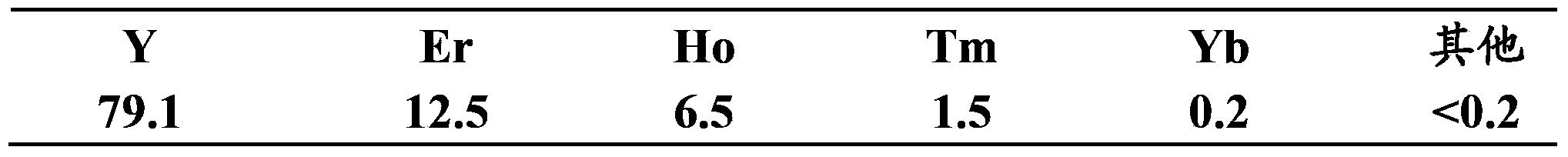

[0115] The yttrium-rich mixed rare earth used in Examples 23 and 29 was purchased from Ganzhou Sanxin New Material Technology Co., Ltd., and the weight percentage (wt%) composition of its main elements is as follows:

[0116] Elemental composition of yttrium-rich mixed rare earths (wt%)

[0117]

[0118] Implementation results of different catalysts in table 2

[0119]

[0120]

[0121]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com