Polyimide/polyolefin complex fiber membrane with cross-linked structure and preparation method

A technology of polyimide fiber and composite fiber membrane, which is applied in fiber processing, filament/thread forming, textile and papermaking, etc., and can solve the problem that mechanical properties and dimensional stability cannot be reflected, there is no strong interaction, and limitations Practical application and other issues, to achieve the effect of good practical application prospects, easy operation, and widening varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Preparation of pyromellitic dianhydride / 4,4'-diaminodiphenyl ether (PMDA / 4,4'-ODA) type polyimide (PI) / polymethyl methacrylate (PMMA) with cross-linked structure Composite fiber membrane.

[0022] A: Weigh 3.2g of PMDA and 2.9g of 4,4'-ODA with a molar ratio of 1:1, and dissolve 4,4'-ODA in 30ml of N,N-dimethylformamide (DMF) solvent at one time , after mechanical stirring for 1 hour, PMDA was added to the reaction system, polycondensed in an ice bath for 6 hours to obtain a polyamic acid solution with a moderate viscosity, the polyamic acid solution was put into a 20ml syringe, and polyamide was prepared by electrospinning technology. Acid fiber membrane, vacuum dried for 12h. Then, the polyamic acid fiber membrane is placed in an electric blast drying oven for thermal imidization with gradient temperature rise to prepare the polyimide fiber membrane. Among them, the electrospinning parameters are: spinning voltage: 25kV; spinning temperature: 25°C; spinning humidity...

Embodiment 2

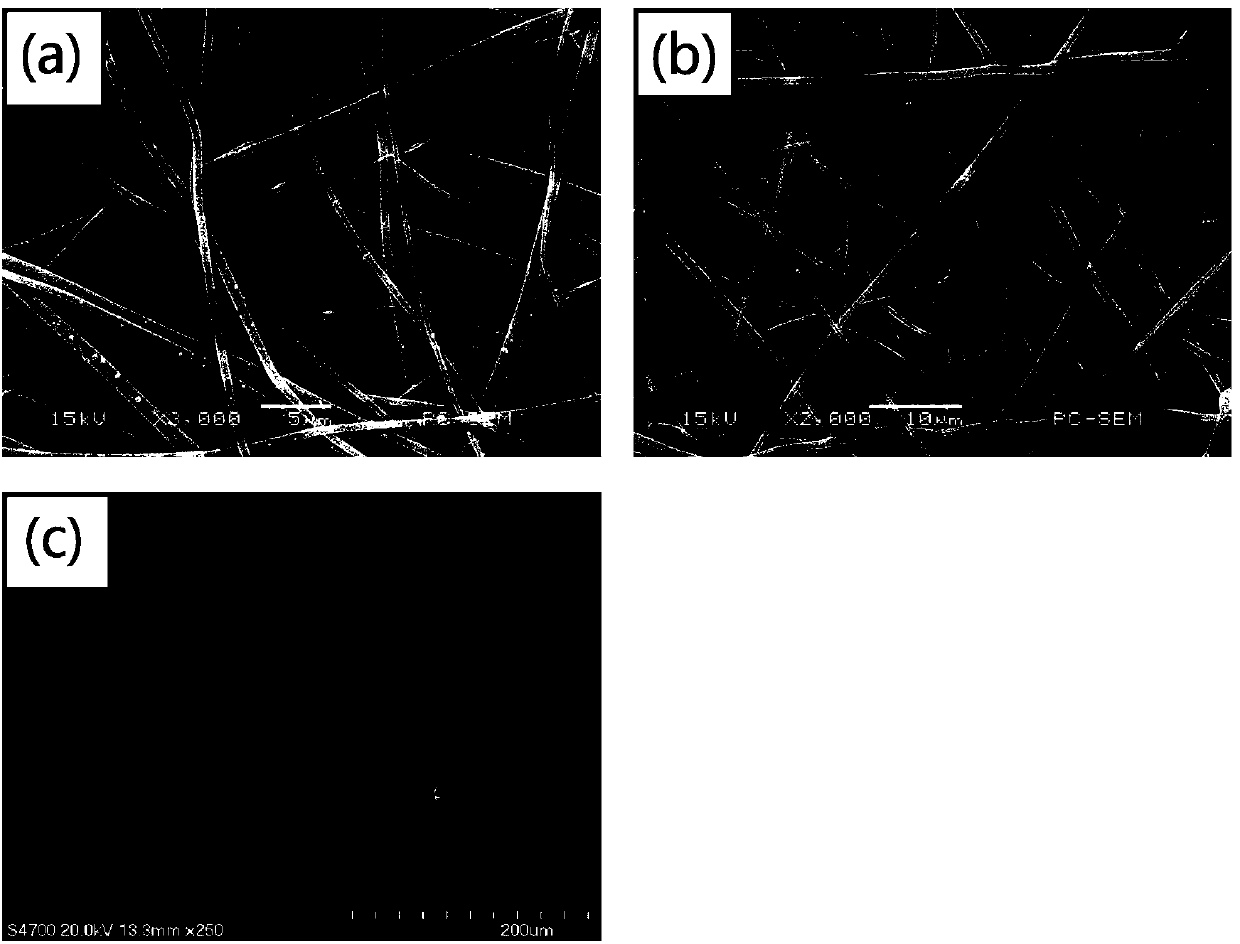

[0027] Preparation of Pyromellitic Dianhydride / 4,4'-Diaminodiphenyl Ether (PMDA / 4,4'-ODA) Type Polyimide (PI) / Polyvinylidene Fluoride (PVDF) Composite with Crosslinked Structure Fiber membrane.

[0028]A: Weigh 3.2g of PMDA and 2.9g of 4,4'-ODA with a molar ratio of 1:1, and dissolve 4,4'-ODA in 30ml of N,N-dimethylformamide (DMF) solvent at one time , after mechanical stirring for 1 hour, PMDA was added to the reaction system, polycondensed in an ice bath for 6 hours to obtain a polyamic acid solution with a moderate viscosity, the polyamic acid solution was put into a 20ml syringe, and polyamide was prepared by electrospinning technology. Acid fiber membrane, vacuum dried for 12h. Then, the polyamic acid fiber membrane is placed in an electric blast drying oven for thermal imidization with gradient temperature rise to prepare the polyimide fiber membrane. Among them, the electrospinning parameters are: spinning voltage: 25kV; spinning temperature: 25°C; spinning humidity: ...

Embodiment 3

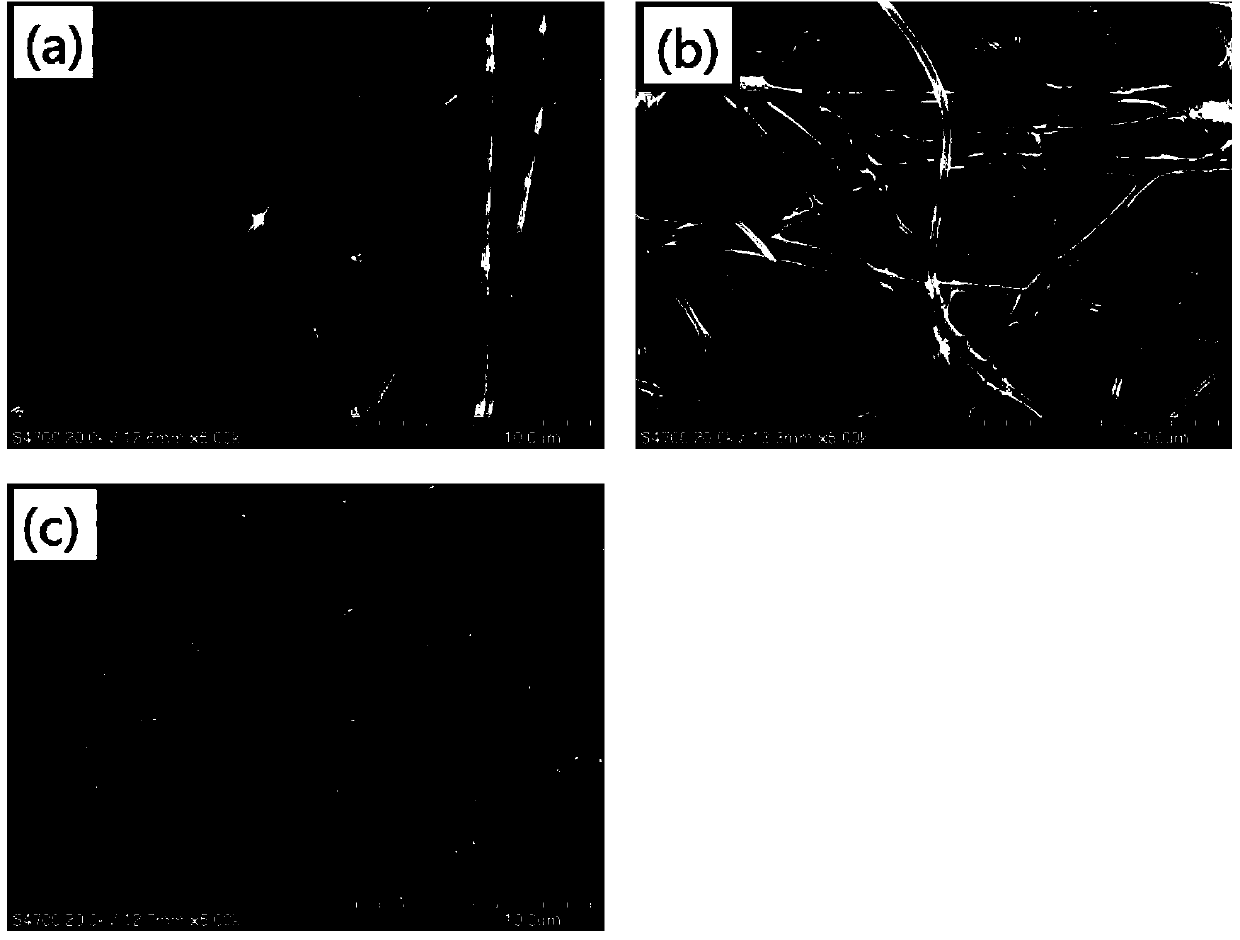

[0033] Preparation of Pyromellitic Dianhydride / 4,4'-Diaminodiphenyl Ether (PMDA / 4,4'-ODA) Type Polyimide (PI) / Polyethylene Oxide (PEO) Composite Fiber with Crosslinked Structure membrane.

[0034] A: Weigh 3.2g of PMDA and 2.9g of 4,4'-ODA with a molar ratio of 1:1, and dissolve 4,4'-ODA in 30ml of N,N-dimethylformamide (DMF) solvent at one time , after mechanical stirring for 1 hour, PMDA was added to the reaction system, polycondensed in an ice bath for 6 hours to obtain a polyamic acid solution with a moderate viscosity, the polyamic acid solution was put into a 20ml syringe, and polyamide was prepared by electrospinning technology. Acid fiber membrane, vacuum dried for 12h. Then, the polyamic acid fiber membrane is placed in an electric blast drying oven for thermal imidization with gradient temperature rise to prepare the polyimide fiber membrane. Among them, the electrospinning parameters are: spinning voltage: 20kV; spinning temperature: 25°C; spinning humidity: 50%; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com