Desulfurizing and purifying device for coke oven gas and application method thereof

A coke oven gas and purification device technology, which is applied in combustible gas purification, combustible gas purification/transformation, gas dust removal, etc., can solve problems such as endangering buildings, strong corrosion and toxicity, and affecting air quality, so as to reduce operating costs , saving equipment investment, stable and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

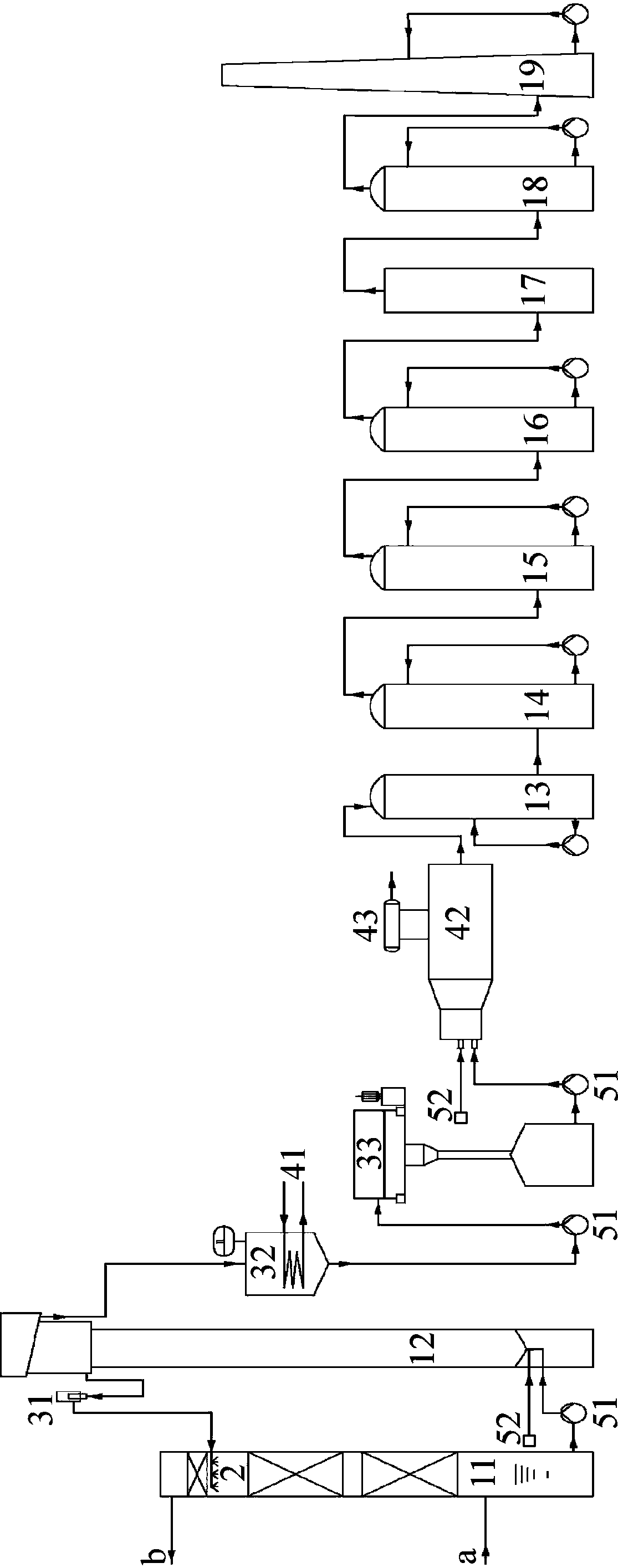

[0027] A desulfurization and purification device for coke oven gas, comprising a desulfurization tower 11, a spray head 2, a regeneration tower 12, a dust removal tower 13, a cooling tower 14, a demister tower 15, a drying tower 16, a conversion tower 17, and an absorption tower 18 , discharge tower 19, dehydration tank 31, preheating tank 32, mother liquor storage tank 33, heat exchanger 41, incinerator 42, waste heat boiler 43, liquid pump 51 and air pump 52, such as figure 1 As shown, the specific structure is:

[0028] The upper part of the desulfurization tower 11 is provided with a coke oven gas outlet, the two sides of the lower part of the desulfurization tower 11 are respectively provided with a coke oven gas inlet and a mother liquor outlet, and the upper part of the desulfurization tower 11 is provided with a spray head 2, which sprays downward Mother liquor;

[0029] The regeneration tower 12 is arranged on one side of the desulfurization tower 11, and the two sid...

Embodiment 2

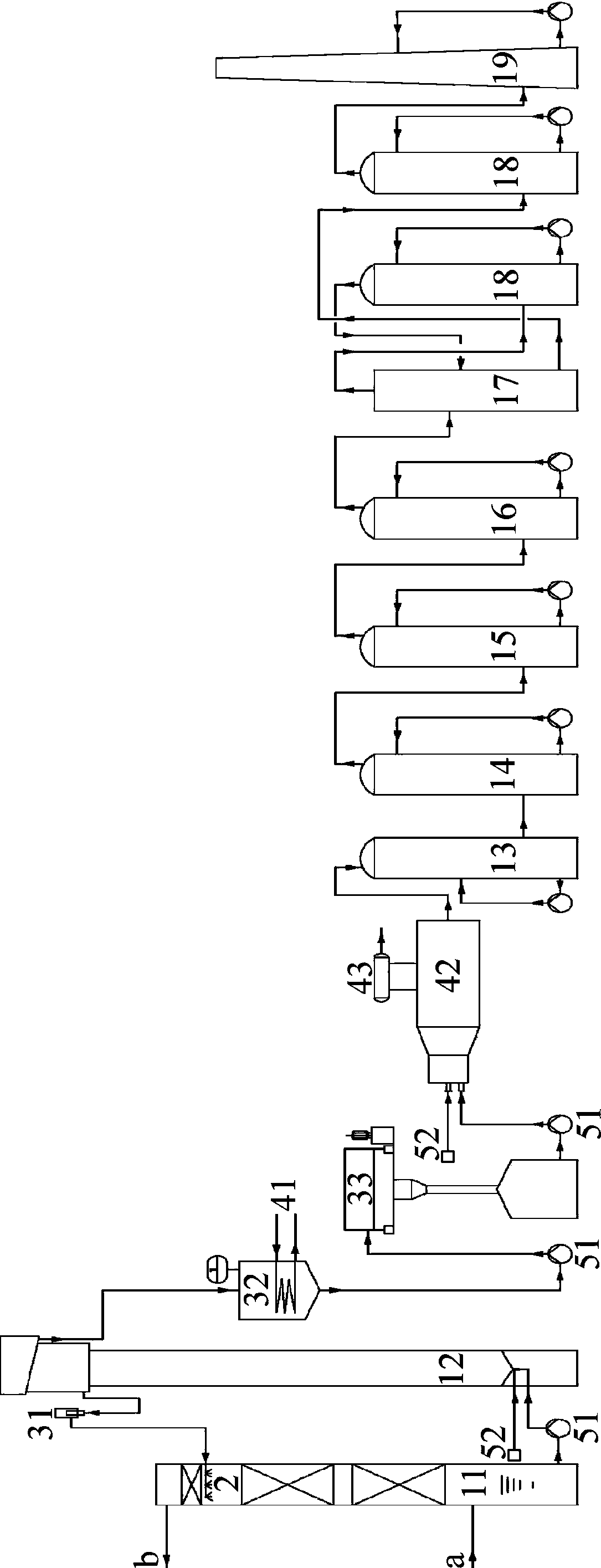

[0043] A desulfurization and purification device for coke oven gas, comprising a desulfurization tower 11, a spray head 2, a regeneration tower 12, a dust removal tower 13, a cooling tower 14, a demister tower 15, a drying tower 16, a conversion tower 17, and an absorption tower 18 , discharge tower 19, dehydration tank 31, preheating tank 32, mother liquor storage tank 33, heat exchanger 41, incinerator 42, waste heat boiler 43, liquid pump 51 and air pump 52, such as figure 2 As shown, the specific structure is: conversion tower 17 is provided with two tail gas inlets and two tail gas outlets, and absorption tower 18 has two, and the tail gas outlet of drying tower 16 top is connected with the first tail gas inlet of conversion tower 17 by tail gas pipe, transforms The first tail gas outlet of the tower 17 is connected to the tail gas inlet of the first absorption tower 18 bottom, the tail gas outlet of the first absorption tower 18 top is connected to the second tail gas in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com