Magnetic flocculating agent and application method thereof

A magnetic flocculant and application method technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve problems such as secondary pollution, achieve the effects of saving operating costs, rapid settlement, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

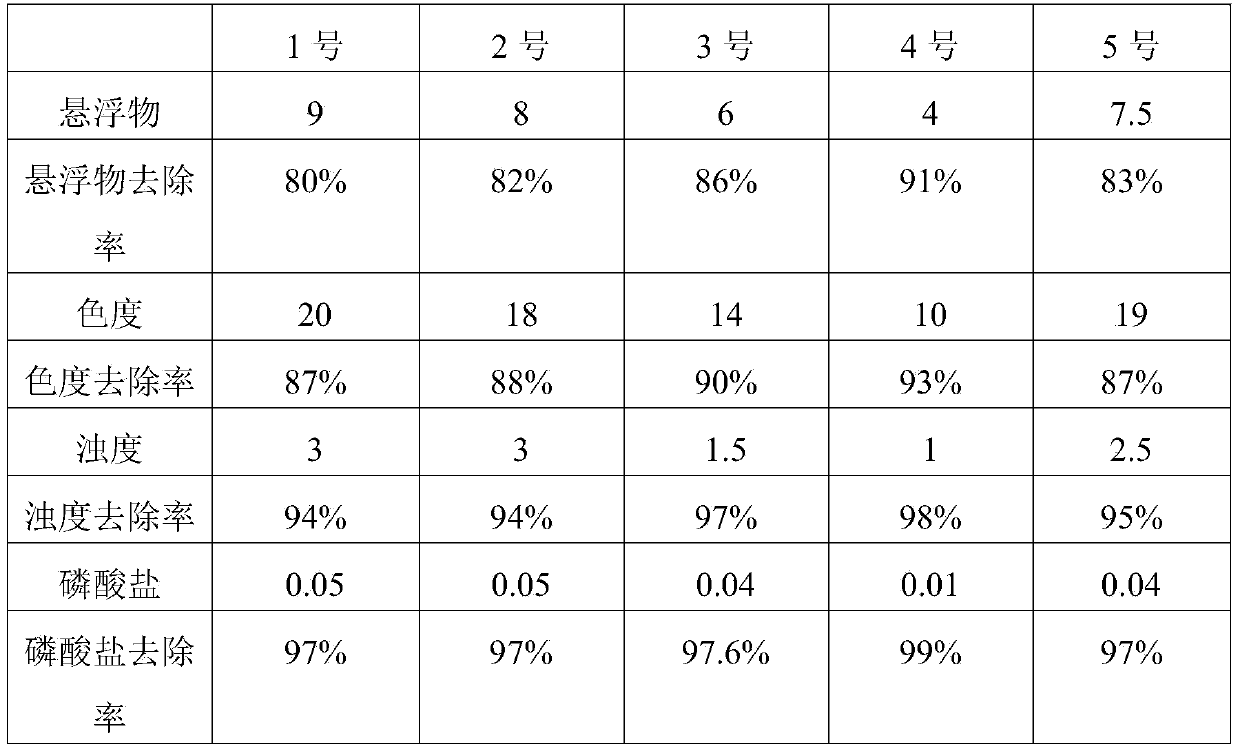

[0018] This experiment adopts the method of comparison, and selects five groups of magnetic flocculant prepared by different ratio formulas. The wastewater treated in this experiment is urban wastewater. 25mg of magnetic flocculant is added to 1000mL of the wastewater, and the modified magnetic flocculant The optimal ratio formula in the agent.

[0019] Wastewater quality: The samples taken in this experiment come from urban sewage treatment plants. The indicators of wastewater pollutants are as follows: suspended solids 45mg / L, chroma 150 (times), turbidity 50 (degrees), phosphate 1.69mg / L.

[0020] The ratio of ferroferric oxide magnetic powder, γ-aminopropyltriethoxysilane and glutaraldehyde in No. 1 magnetic flocculant is 100:0.5:0.5;

[0021] The ratio of ferroferric oxide magnetic powder, γ-aminopropyltriethoxysilane and glutaraldehyde in No. 2 magnetic flocculant is 100:0.6:0.6;

[0022] The ratio of ferroferric oxide magnetic powder, γ-aminopropyltriethoxysilane and g...

Embodiment 2

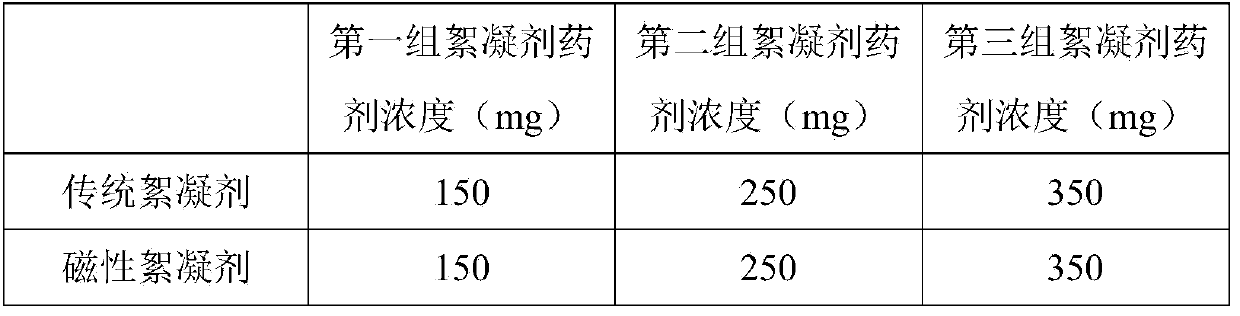

[0030] This experiment adopts the comparative method, one is to use the flocculant prepared by the traditional reagent combination method to treat the fish processing wastewater, and the other is to treat the fish processing wastewater with the magnetic flocculant prepared by No. 4 scheme in Example 1, The treatment method adopts the beaker experiment, and the treatment volume of each fish processing wastewater is 1000mL. As shown in Table 2, three groups of flocculants with different addition amounts were selected for comparative experiments, and the COD content in the treated wastewater used was 3800 mg / L.

[0031] Table 2 Data table of three groups of different flocculants

[0032]

[0033] Take the traditional flocculant and magnetic flocculant with the addition amount of 150mg, 250mg and 350mg respectively, put the three groups of flocculants into the wastewater with COD content of 3800mg / L,

[0034] The COD content in the wastewater was measured respectively, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com