Preparation method of diatomite and paraffin composite phase change material

A composite phase change material and phase change material technology, applied in the field of building energy conservation, can solve the problems of cumbersome preparation process, high production cost, leakage of phase change process, etc., and achieve the effect of simple preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Implement a preparation method of diatomite and paraffin-based composite phase change material, the steps of the preparation method are as follows.

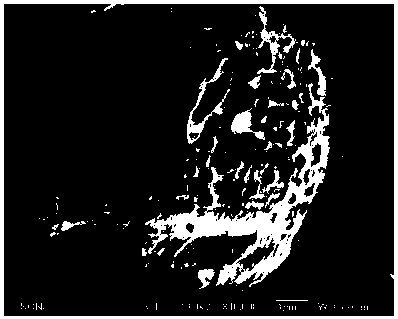

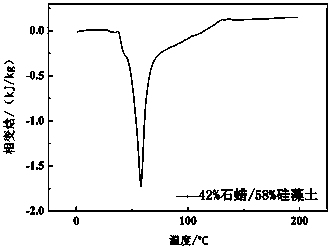

[0050] (1) Dissolve 42wt% phase change material paraffin (sliced) in petroleum ether in water at a temperature of 50°C, and stir for 1 hour with an electromagnetic stirrer to fully dissolve it in petroleum ether (petroleum ether The dosage is twice the volume of paraffin and diatomaceous earth).

[0051] (2) In the above step (1), add the carrier material 58wt% diatomite (Jilin Province, a natural mineral, widely distributed in my country and has a large reserve, and is cheap and easy to obtain), and continue to stir fully to make the diatomite pore structure It can fully contact with the phase change material paraffin, and its surface tension and physical force can fully exert the adsorption of a sufficient amount of paraffin.

[0052] (3) After the diatomite fully absorbs the paraffin, raise the temperature of the water...

Embodiment 2

[0057] Implement a preparation method of diatomite and paraffin-based composite phase change material, the steps of the preparation method are as follows.

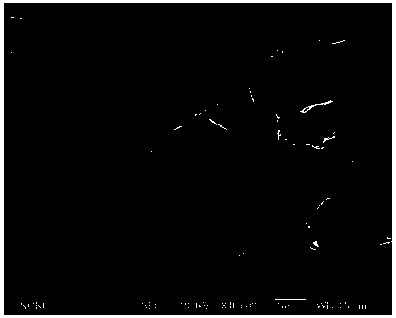

[0058] (1) At room temperature, dissolve 38wt% paraffin wax (n-octadecane), a phase change material, in petroleum ether, and stir for 1 hour with an electromagnetic stirrer to fully dissolve it in petroleum ether (petroleum ether The amount of ether used is twice the volume of paraffin and diatomaceous earth).

[0059] (2) In the above step (1), add the carrier material 62wt% diatomite (same as in Example 1), and continue to stir fully, so that the diatomite pore structure can fully contact with the phase change material paraffin, and its surface tension And the physical force can fully play the role of absorbing enough paraffin.

[0060] (3) After the diatomite fully absorbs the paraffin, raise the temperature of the water area to 75°C to completely evaporate the petroleum ether as a solvent, and install a circulating w...

Embodiment 3

[0066] Implement a preparation method of diatomite and paraffin-based composite phase change material, the steps of the preparation method are as follows.

[0067] (1) Just at room temperature, dissolve 35wt% of the phase change material paraffin (this is n-dodecane) in petroleum ether, and stir it with an electromagnetic stirrer for 1 hour to fully dissolve it in petroleum ether (petroleum The amount of ether used is twice the volume of paraffin and diatomaceous earth).

[0068] (2) In the above step (1), add 65wt% diatomite as a carrier material (same as in Example 1), and continue to stir fully so that the diatomite pore structure can fully contact with the phase change material paraffin, and its surface tension And the physical force can fully play the role of absorbing enough paraffin.

[0069] (3) After the diatomite fully absorbs the paraffin, raise the temperature of the water area to 75°C to completely evaporate the petroleum ether as a solvent, and install a circul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| phase | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com