Method for preparing VCI double-metal composite coating

A composite coating and bimetal technology, used in anti-corrosion coatings, coatings and other directions, can solve the problems of high energy consumption, electrolyte solution pollution, and difficult to handle in the anodizing process, and achieves inhibition of the formation of white zinc oxide, easy pretreatment, The effect of addressing harm to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

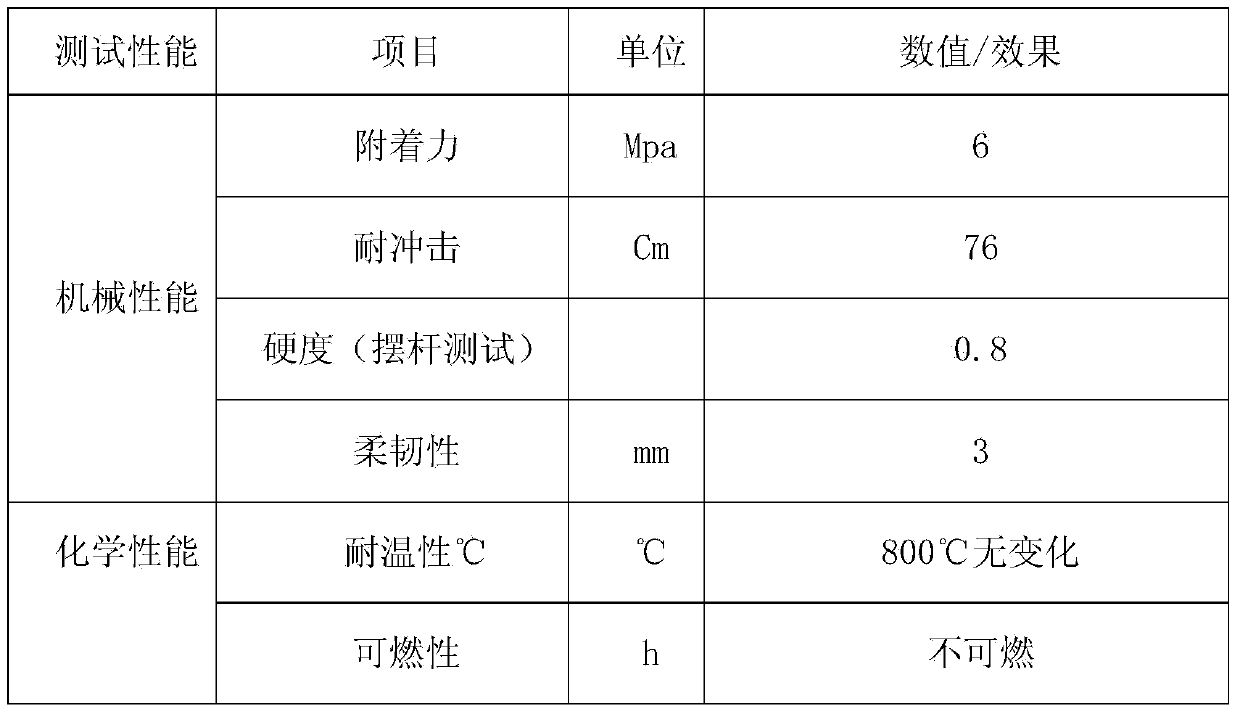

Embodiment 1

[0032] This embodiment provides a preparation method of a VCI bimetallic composite coating, the VCI bimetallic composite coating comprises the following components by mass percentage: moisture-curing silicone resin: 35%, aluminum powder: 35%, zinc powder: 28%, Ethanol: 2% The preparation method of this VCI bimetal composite coating specifically comprises the following steps:

[0033] (1) Take 35% of the moisture-curing silicone resin and 2% of ethanol according to the mass percentage and put it into the dispersion tank for stirring, the stirring speed is 450 rpm, and stir for 25 minutes to obtain a uniform premix;

[0034] (2) Take 35% of aluminum powder by mass percentage and add it to the premix prepared in step (1) under stirring, then add 28% of zinc powder, adjust the rotating speed to 500 rpm, stir for 40min, and control the dispersion cylinder The temperature is 30°C, the detected viscosity is 100s, the solid content is 70%, and the VCI bimetallic composite coating is p...

Embodiment 2

[0040] This embodiment provides a preparation method of a VCI bimetallic composite coating, the VCI bimetallic composite coating comprises the following components by mass percentage: moisture-curing silicone resin: 21%, aluminum powder: 45%, zinc powder: 30%, Butanol: 4% The preparation method of this VCI bimetallic composite coating specifically comprises the following steps:

[0041] (1) Take 21% of the moisture-curing silicone resin and 4% of n-butanol according to the mass percentage and put it into the dispersion tank for stirring, the stirring speed is 400 rpm, and stir for 20 minutes to obtain a uniform premix;

[0042] (2) Take 45% of aluminum powder by mass percentage and add it to the premix prepared in step (1) under stirring, then add 30% of zinc powder, adjust the rotating speed to 550 rpm, stir for 25min, and control the dispersion cylinder The temperature is 25°C, the detected viscosity is 95s, the solid content is 75%, and the VCI bimetallic composite coating ...

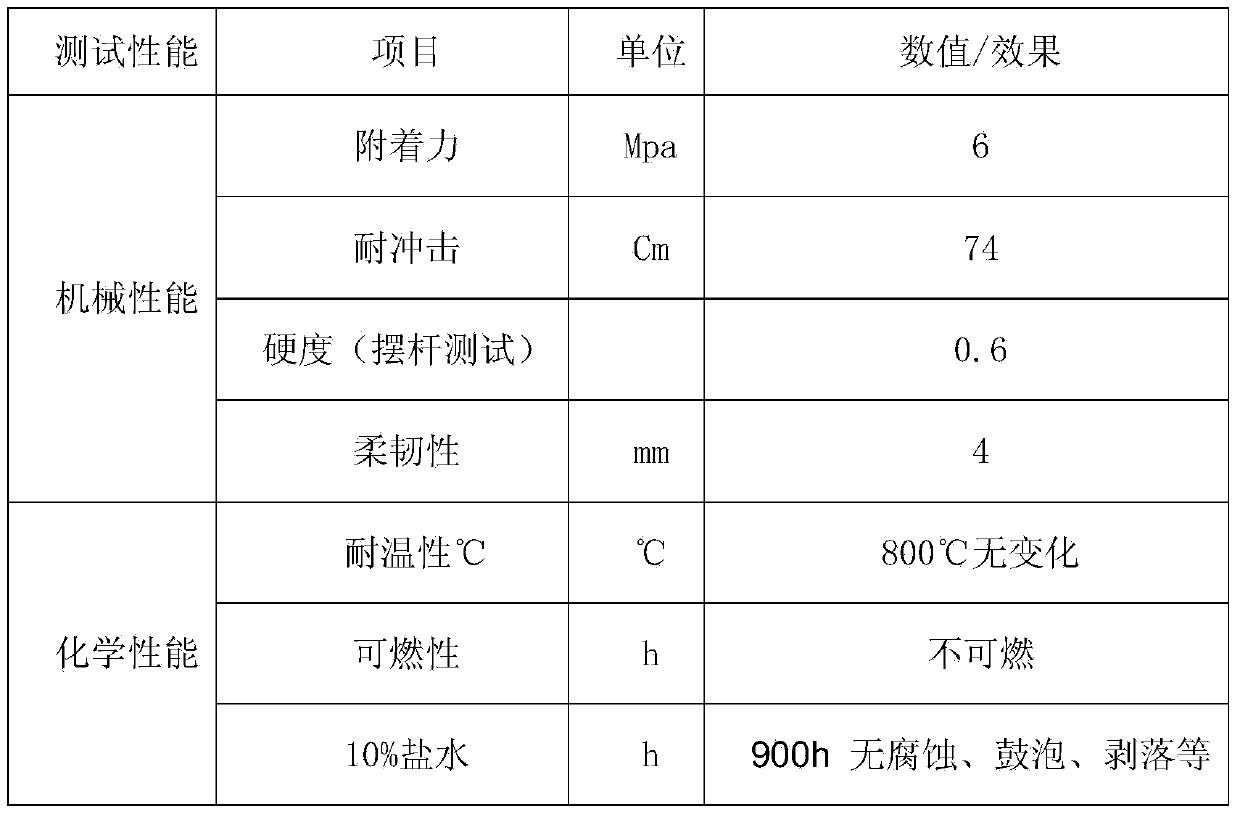

Embodiment 3

[0047] This embodiment provides a kind of preparation method of VCI bimetallic composite coating, and this VCI bimetallic composite coating comprises the following components by mass percentage: Moisture-curing silicone resin: 36%, aluminum powder: 36%, zinc powder: 25%, Ethanol: 3% The preparation method of this VCI bimetal composite coating specifically comprises the following steps:

[0048] (1) Take 36% of the moisture-curing silicone resin and 3% of ethanol according to the mass percentage and put them into the dispersion tank for stirring, the stirring speed is 500 rpm, and stir for 30 minutes to obtain a uniform premix;

[0049] (2) Take 36% of aluminum powder according to the mass percentage and add it to the premix prepared in step (1) under stirring, then add 25% of zinc powder, adjust the rotating speed to 600 rpm, stir for 50min, and control the dispersion cylinder The temperature is 35°C, the detected viscosity is 105s, the solid content is 79%, and the VCI bimeta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com