Printing ink for polypropylene material and preparation method thereof

A polypropylene material, printing ink technology, applied in the direction of ink, application, household appliances, etc., can solve the problems of many matrix components, high cost, shortening and thickening of molecular chains, etc., to reduce environmental pollution and good flexibility resistance. , the effect of reducing the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

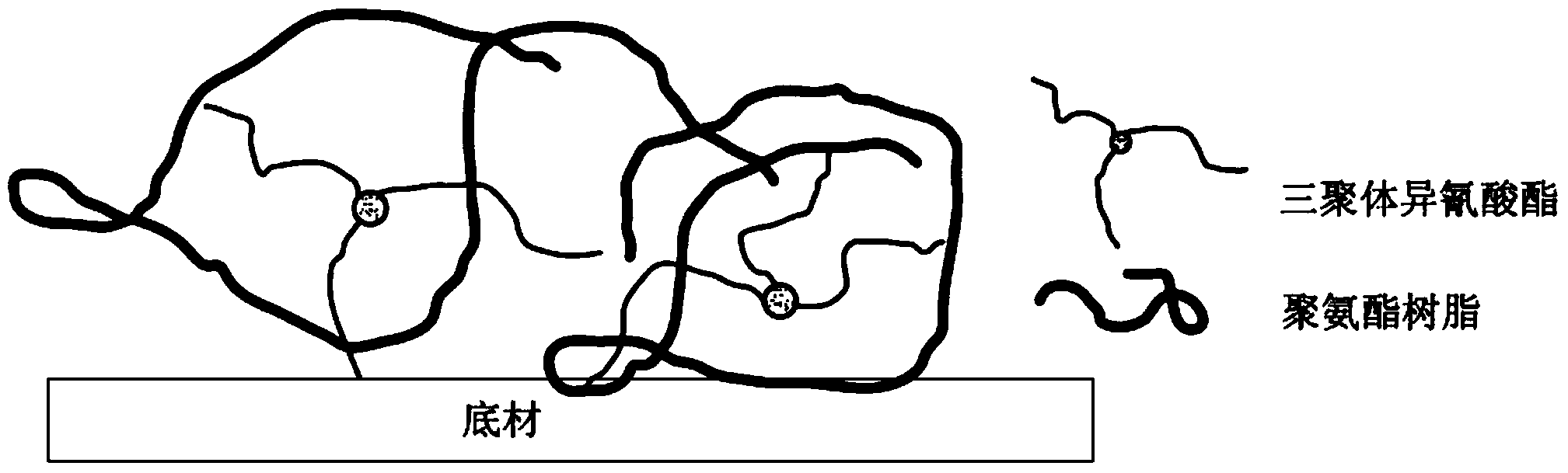

Method used

Image

Examples

Embodiment 1

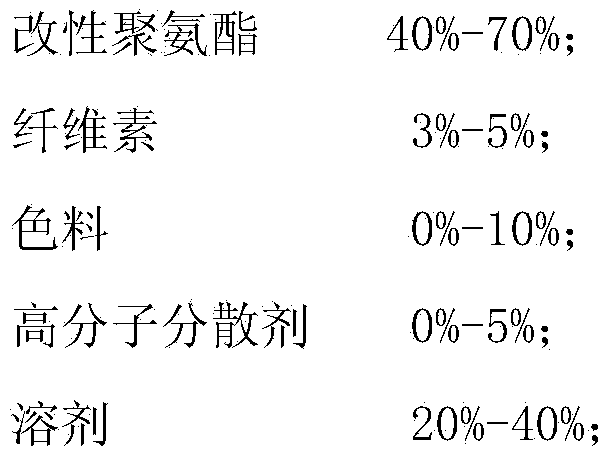

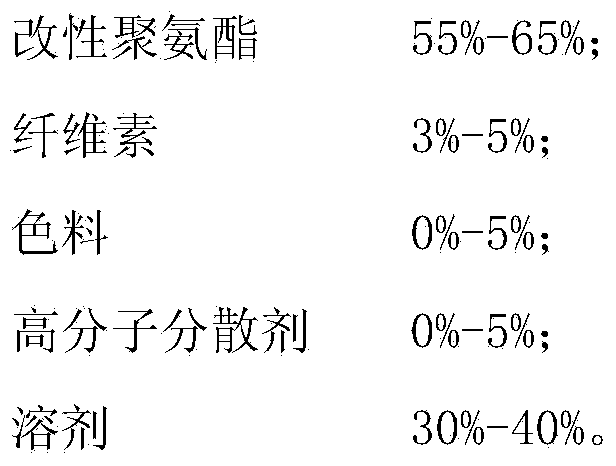

[0039] Embodiment 1: A kind of printing ink for polypropylene material, described printing ink for polypropylene material is made up of A component and B component, wherein, the number ratio of A component and B component is A component: B Components=100:1; the component A includes, by mass percentage: 60% modified polyurethane, 3% cellulose, 3% pigment, 4% polymer dispersant, and 30% solvent. The B component is a hardener. The solvent used in this example is a mixed solvent of butyl ester and isopropanol.

[0040] The preparation method of the printing ink for polypropylene material of the present embodiment comprises the steps:

[0041] Step 1: Add solvent, polymer dispersant, and cellulose to the stirring container in sequence, and stir the stirring container at a speed of 800 rpm until the components are evenly mixed to obtain a mixture; Step 2: Add coloring material and Modified polyurethane, the stirring container was stirred at a rotating speed of 800rpm for 90min, so...

Embodiment 2

[0042] Example 2: A printing ink for polypropylene materials, consisting of component A and component B, the ratio of the two is component A: component B = 100:1, the component A is by mass percentage , including the following components:

[0043] 60% modified polyurethane, 3% cellulose, 2% titanium dioxide, 2% polymer dispersant, 33% solvent; the B component is a hardener. What cellulose adopted in the present embodiment is the CAB381-2 that U.S. Eastman Company produces; What hardener adopts is the D-110N that Mitsui Chemicals produces; What polymer dispersant adopts is the SOLSPERE that lubrizol Company produces; What solvent adopts is ethyl acetate The mixed solvent compounded by ester and isopropanol; the product of trade name F-206X produced by manufacturer Arakawa Chemical Industry Co., Ltd. for use of modified polyurethane.

[0044] The preparation method of the printing ink for polypropylene material of the present embodiment comprises the steps:

[0045] Step 1: Ad...

Embodiment 3

[0046] Example 3: A printing ink for polypropylene materials, consisting of A component and B component, the ratio of A component to B component is A component: B component = 100:5, the A Components include by mass percentage:

[0047] 70% modified polyurethane, 5% cellulose, and 25% solvent; the B component is a hardener. What the cellulose used in this embodiment is CAB381-2 produced by U.S. Eastman Company; what the hardener adopts is D-110N produced by Mitsui Chemicals; The product of Arakawa Chemical Industry Co., Ltd. under the trade name F-206X.

[0048] The preparation method of the printing ink for polypropylene material of the present embodiment comprises the steps:

[0049] Step 1: Add the mixed solvent and cellulose to the stirring container in turn, and stir the stirring container at a speed of 1000rpm until the components are evenly mixed to obtain a mixture; Step 2: Add modified polyurethane to the mixture in Step 1, and stir the container Stir at 800rpm for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com