Diamond synthesis device with super-large cavity

A diamond and cavity technology, applied in the field of super-large cavity diamond synthesis device, can solve the problems of difficulty in ensuring the heat preservation and stability of the synthesis device, good thermal conductivity of metal, easy melting, etc., and achieves reduction of synthesis cost, stable particle size distribution, The effect of improving heat retention and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

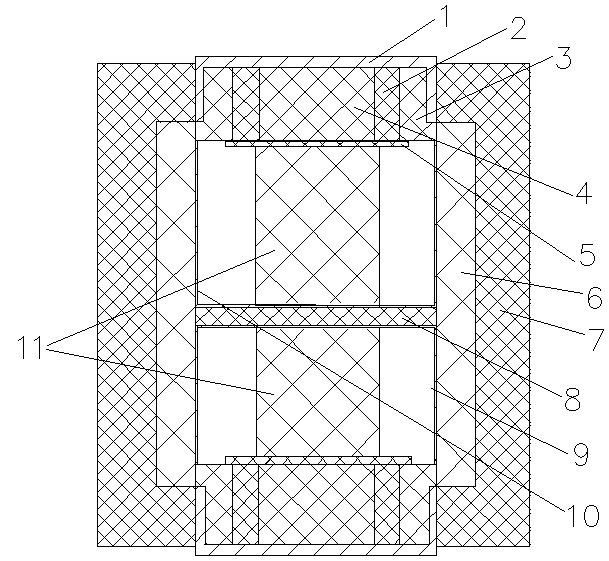

[0013] see figure 1 , the present invention includes a super-large cavity used as a diamond synthesis container, the diameter (inner diameter) of the super-large cavity is 55-58mm, and the super-large cavity is provided with an upper iron cup 10 and a lower iron cup 9 along the axial direction, and an upper iron cup 12 The mouth of the cup faces upward, the mouth of the lower iron cup 9 faces downward, and a heating sheet 8 is provided between the bottom of the upper iron cup and the bottom of the lower iron cup, and the heating sheet 8 is in contact with the bottom of the upper iron cup and the bottom of the lower iron cup respectively Electrically connected, the heating sheet is a disc made of graphite and dolomite mixed and pressed at a weight ratio of 1:0.5-1:2. The upper end of the cup mouth of the upper iron cup 10 and the lower end of the cup mouth of the lower iron cup 9 are respectively provided with a composite layer, the outer layer of the composite layer is an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com