Reaction device and preparation method of nitrogen doped silicon carbide film

A technology of reaction equipment and silicon carbide, which is applied in gaseous chemical plating, semiconductor/solid-state device manufacturing, coating, etc., can solve problems such as enhanced adhesion, increased K value, and decreased adhesion, so as to improve reliability and Electrical performance, improvement of process quality, and effect of enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be further described below in conjunction with the accompanying drawings. Of course, the present invention is not limited to this specific embodiment, and general replacements known to those skilled in the art are also covered within the protection scope of the present invention.

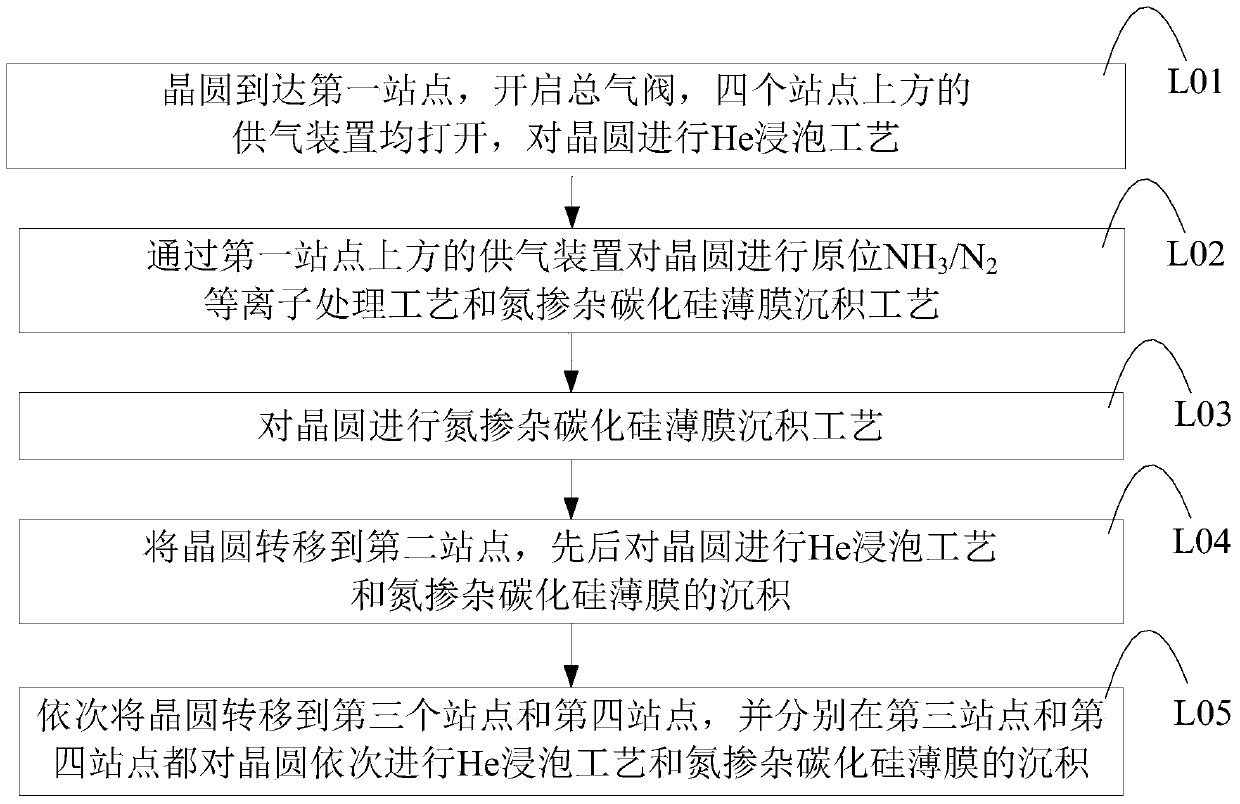

[0031] In the present invention, the reaction equipment for nitrogen-doped silicon carbide film can adopt the existing reaction equipment for nitrogen-doped silicon carbide film, which has a reaction chamber, usually the reaction chamber has first, second, third and The fourth station, above each station, includes an air supply device, such as an air intake shower head, etc., there may be a transfer device between the four stations so that the wafers can be transferred between them, and there are also separate facilities in the reaction equipment. Control the radio f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com