A High Resonance Frequency Scanner for Scanning Tunneling Microscopy

A technique of resonant frequency and scanning tunnel, which is applied in the direction of scanning probe microscopy, scanning probe technology, instruments, etc., can solve the problems of low resonance frequency, low production frequency, and large noise, and achieve improved accuracy and stability, The effect of reducing temperature drift and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The above-mentioned contents of the present invention are described in further detail below through the embodiments, but this should not be interpreted as the scope of the above-mentioned themes of the present invention being limited to the following embodiments, and all technologies realized based on the above-mentioned contents of the present invention all belong to the scope of the present invention.

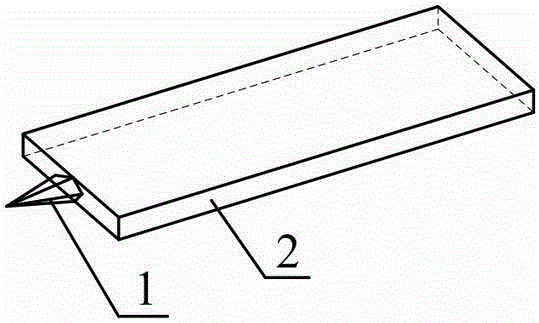

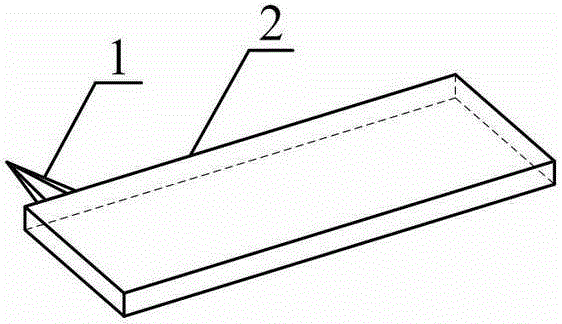

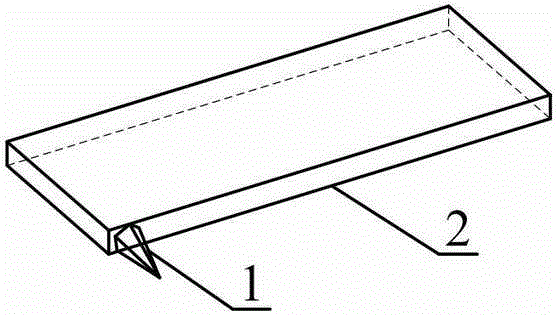

[0020] A high-resonance frequency scanner suitable for scanning tunneling microscopes, including a micron-scale needle tip 1 and a micro-cantilever beam 2 integrally formed by micro-nano processing technology, wherein the needle tip 1 is located on the narrow surface of the micro-cantilever beam 2 and the direction of the needle tip 1 is consistent with the The included angle of the normal line of the narrow surface of the micro-cantilever beam 2 is not more than 45°, and the materials of the needle tip 1 and the micro-cantilever beam 2 are all single crystal silicon or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com