Fiber oxidase composition for changing and improving properties of fibers, paper making method and application

A technology of fiber oxidase and composition, applied in the direction of oxidoreductase, textiles and papermaking, biochemical equipment and methods, etc., can solve the problems of reducing pulping freeness, reducing fiber yield, increasing paper density, etc., to achieve increased Effects of fiber reactivity, reduction of refining performance, and modification of beating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

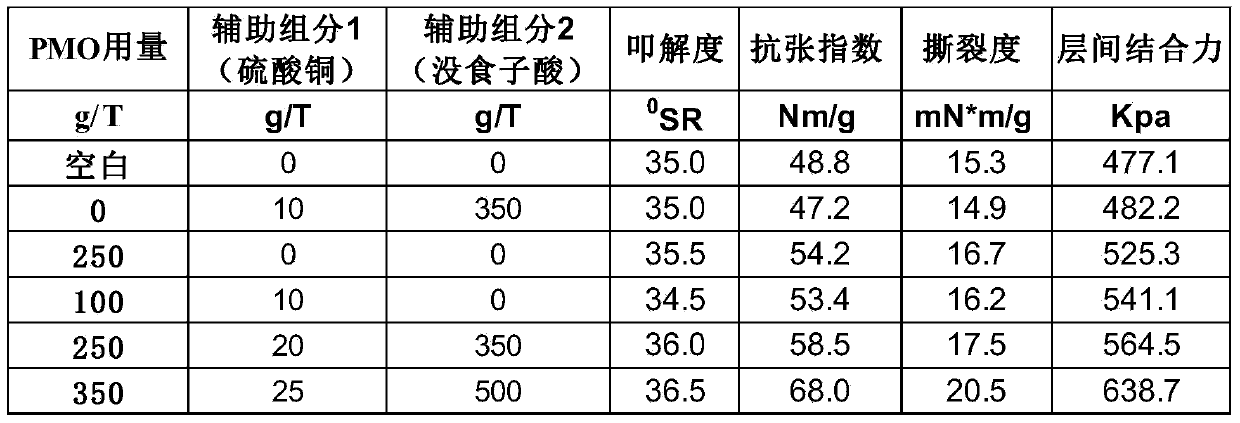

[0074] Example 1 Effect of fiber oxidase and its different compositions on paper strength of bleached hardwood pulp

[0075] 1. Purpose of the experiment

[0076] The effects of fiber oxidase and its composition on the paper strength of bleached hardwood pulp were evaluated by comparative analysis.

[0077] 2. Experimental method

[0078] (1) Test material preparation

[0079] Bleached broadleaf chemical pulp is provided by the pulp mill of Shandong Wanguo Paper Industry No. 26.

[0080] Fiber oxidase (PMO) is GH61 provided by American Dyadic Company. This enzyme is produced from the strain Myceliophthora thermophila9 (also known as Sporotrichum thermophile). Its amino acid sequence is described in detail in US Pat.

[0081] The cellulolytic enzyme is the commercial product FiberZymeG200 of Dyadic Company, which is produced by the same bacterial strain as above. Other chemicals were purchased from SigmaAldrich.

[0082] (2) Papermaking method

[0083] A, pulping: 200 gra...

Embodiment 2

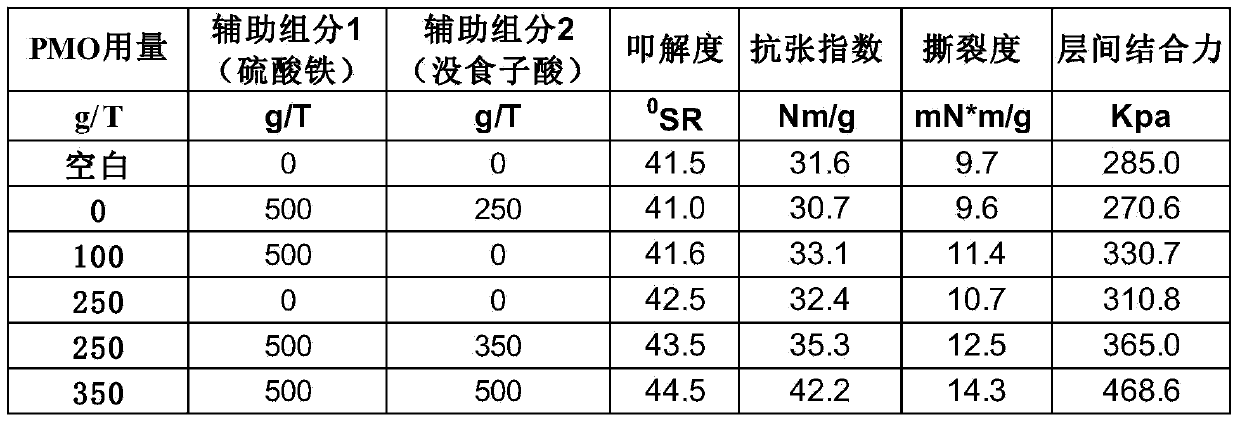

[0103] Example 2 Effect of fiber oxidase and its different compositions on paper strength of mechanical softwood pulp

[0104] 1. Purpose of the experiment

[0105] The effects of fiber oxidase and its different compositions on mechanical softwood pulp on its paper strength were evaluated by comparative analysis.

[0106] 2. Experimental method

[0107] (1) Test material preparation

[0108] The mechanical softwood pulp was supplied by the pulp mill of Shandong Wanguo Paper Industry No. 26.

[0109] Fiber oxidase (PMO) is GH61 provided by Dyadic Company of the United States. This enzyme is produced from the strain Myceliophthora thermophila. Its amino acid sequence is described in detail in US Patent No. 8,298,795 and US Patent Application USA2012 / 0083019.

[0110] The cellulolytic enzyme is the commercial product FiberZyme G200 of Dyadic Company, which is produced by the same bacterial strain as above.

[0111] (2) Papermaking method

[0112] A, pulping: 200 grams of pul...

Embodiment 3

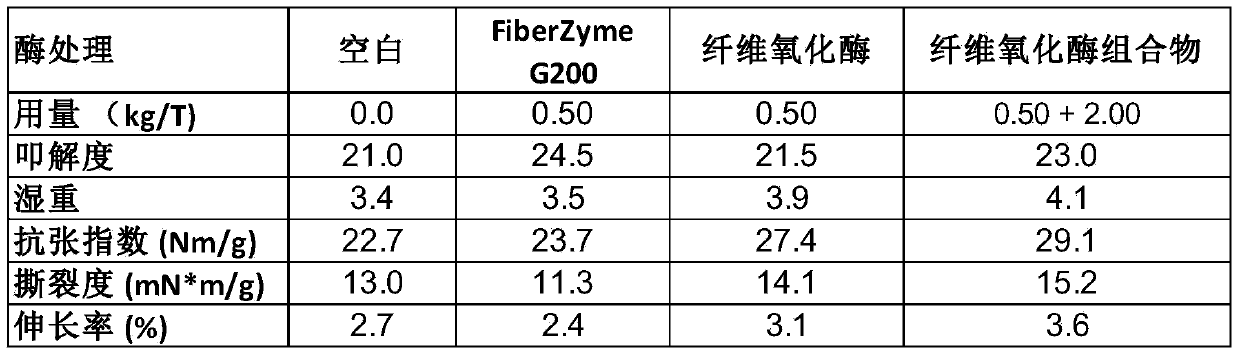

[0131] Example 3 Effect of fiber oxidase and its composition on paper strength of unbleached chemical softwood pulp

[0132] 1. Purpose of the experiment

[0133] The effects of fiber oxidase and its different compositions on the paper strength of unbleached chemical softwood pulp were evaluated by comparative analysis.

[0134] 2. Experimental method

[0135] (1) Test material preparation

[0136] Unbleached chemical pulp (softwood pulp) was provided by Zhejiang Rongcheng Paper Industry.

[0137] Fiber oxidase (PMO) is GH61 provided by Dyadic Company of the United States. This enzyme is produced from the strain Myceliophthora thermophila. Its amino acid sequence is described in detail in US Patent No. 8,298,795 and US Patent Application USA2012 / 0083019.

[0138] The cellulolytic enzyme is the commercial product FiberZyme G200 of Dyadic Company, which is produced by the same bacterial strain as above.

[0139] (2) Papermaking method

[0140] A, pulping: 200 grams of pulp ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com