Method for producing board layers of freeze dryers by utilizing aluminum alloy sections

A technology of aluminum alloy profile and production method, which is applied in the production field of using aluminum alloy profile to produce freeze dryer plate, can solve problems such as difficulty in meeting technical design requirements, affecting plate surface flatness, and difficulty in guaranteeing external dimensions, etc., to achieve The effect of improving the quality of drug production, shortening the production cycle, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

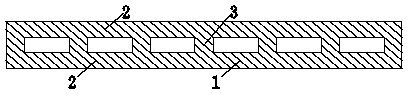

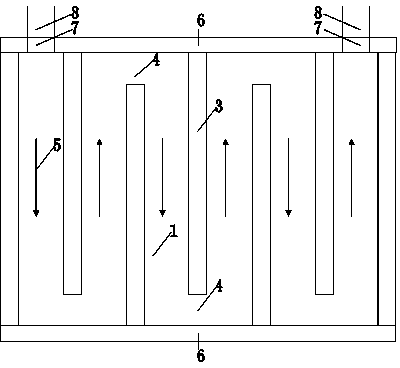

[0009] A production method of using aluminum alloy profiles to produce freeze dryer sheets, characterized in that it consists of the following steps: (1) rolling aluminum alloy profiles, (2) cutting aluminum alloy profiles, (3) machining of cut surfaces, (4) Sealing of the cutting surfaces at both ends, (5) Process the liquid inlet pipe and liquid outlet pipe. The rolled aluminum alloy profile described in step (1) is a rolled plate, and several pipe holes are arranged on the cross section of the plate. The tube hole is a rectangular hole. The step (2) of cutting the aluminum alloy profile is to cut the rolled aluminum alloy plate transversely according to the length required. The step (3) machining of the cut surface is to process the surface of the cut surface with a through groove and a sealing surface. The processing of the through grooves is to mill the intervals between the tube holes of the aluminum alloy profiles, the milled intervals are only milled on one end face ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com