Inverter surge-resistant insulated wire and method for producing same

一种绝缘电线、变频器的技术,应用在绝缘电缆、电缆/导体制造、绝缘导体等方向,能够解决无法维持电绝缘性、电绝缘性维持特性降低、比重差等问题,达到电绝缘性维持特性优异、局部放电起始电压高、优异耐热老化特性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0120] A flat conductor (copper with an oxygen content of 15 ppm) having a size of 1.8×3.4 mm (thickness×width) and a chamfering radius r=0.3 mm at the four corners was prepared. When forming the enamelled layer, use a mold similar to the shape of the conductor to apply polyamide-imide resin (PAI) varnish (manufactured by Hitachi Chemical Co., Ltd., trade name: HI406) to the conductor, and set the sintering time to 15 seconds. The speed is such that it passes through an 8-m-long sintering furnace set at 450° C., and a varnish layer with a thickness of 5 μm is formed in the primary sintering process. This step was repeated 8 times to form an enameled layer with a thickness of 40 μm to obtain an enameled wire.

[0121] Next, polyetherimide resin (PEI) (manufactured by Sabic Innovative Plastics, trade name: ULTEM1010) was dissolved in N-methyl-2-pyrrolidone (NMP) to obtain a 20% by mass solution to obtain a resin varnish, The enameled wire is coated on the above-mentioned enamel...

Embodiment 2~18、 and comparative example 1~10 and 13

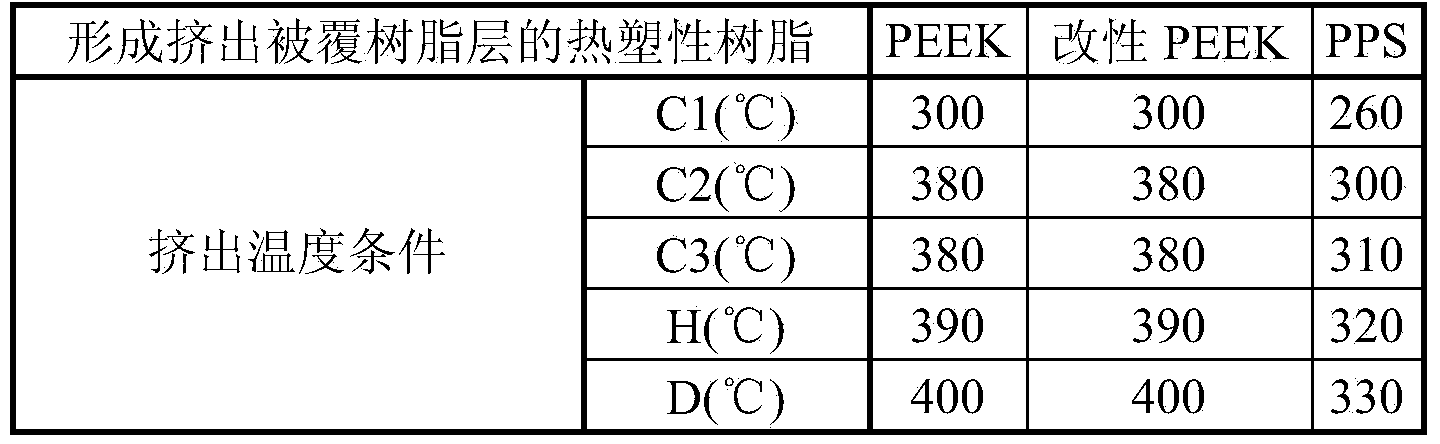

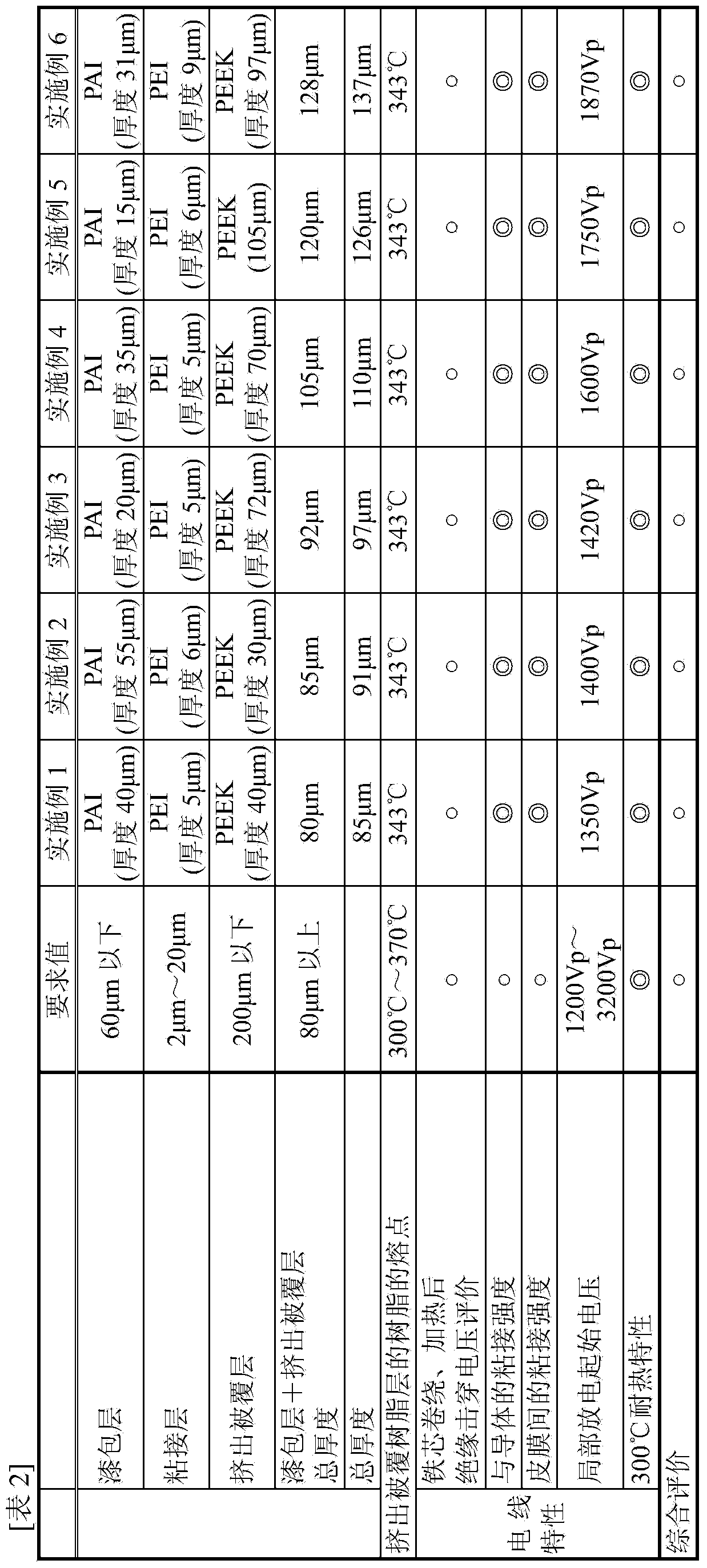

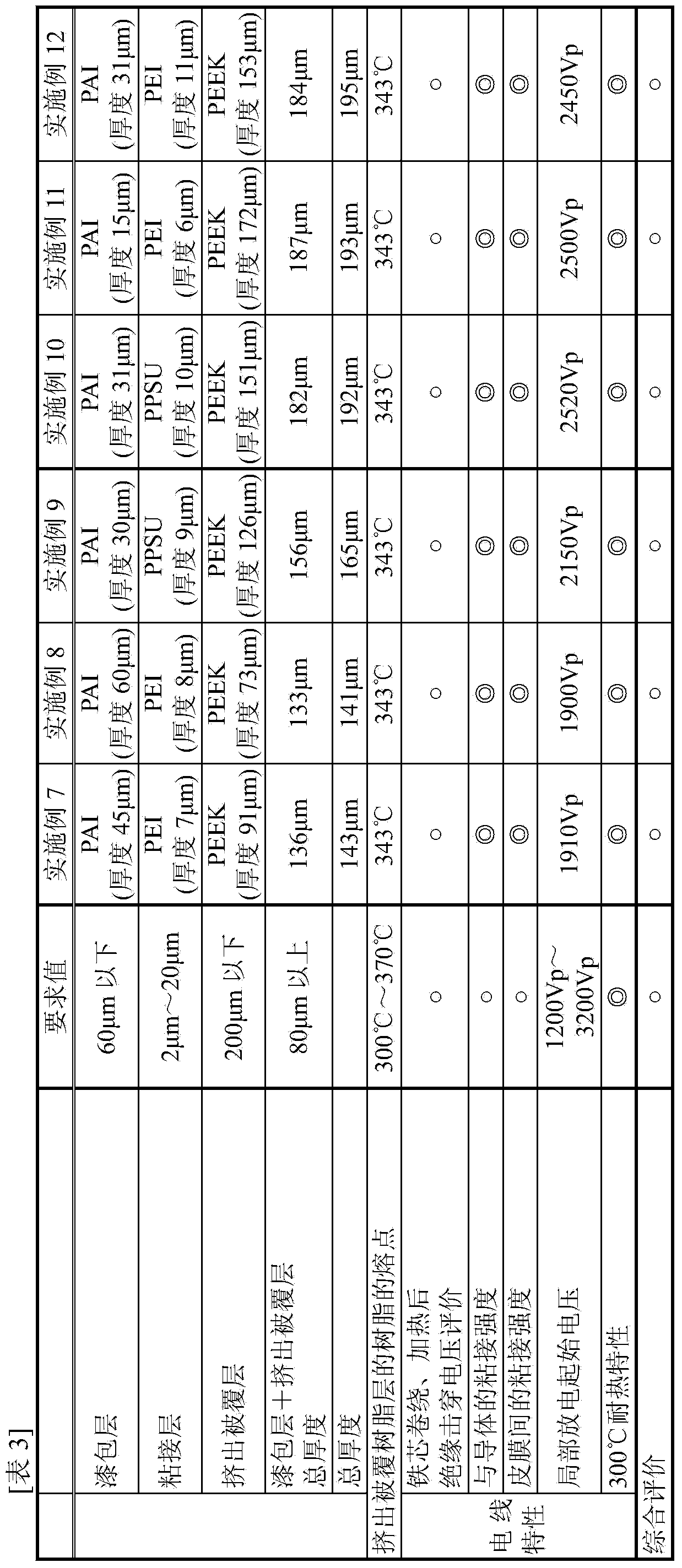

[0124] Insulated wires were obtained in the same manner as in Example 1, except that the types and thicknesses of the resin of the enamel layer, the resin of the adhesive layer, and the resin of the extruded coating resin layer were changed as shown in Tables 2 to 6 below. . It should be noted that the extrusion temperature conditions were based on Table 1. In addition, in Table 2 - Table 6, the extrusion resin coating layer is shown as "extrusion coating layer".

[0125]Here, in Tables 2 to 6, polyimide resin (PI) varnish (manufactured by Unitika, trade name: U Imide) was used for the enamelled layer of Example 13, and the bonding of Examples 9 and 10 and Comparative Example 2 was performed. As a layer, polyphenylsulfone resin (PPSU) (manufactured by Solvay Specialty Polymers, brand name: Radel R5800, glass transition temperature: 220° C.) was used. In addition, the extrusion coating resin layer used modified polyetheretherketone resin (modified PEEK) (manufactured by SOLVA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com