High-resistivity rare earth iron series R-Fe-B magnet and manufacturing method thereof

A high-resistivity, r-fe-b technology, applied in the manufacture of inductors/transformers/magnets, magnetic objects, circuits, etc., can solve problems such as the decline in magnetic properties of magnets, and achieve reduced eddy current loss, improved efficiency, and eddy current loss Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] a. Use grade 40UH, composition: Nd26.5Dy5.5B1.03Nb0.1Al0.1Col.0Cu0.1Ga0.1Fe65.57 (mass percentage) smelted neodymium iron boron alloy cast piece, using hydrogen crushing and jet milling Powder process, made into raw material fine powder with an average particle size of 3.2 microns for use.

[0016] b. Feed the material into the hopper to make a blank of 40*40*25 (orientation size) square size. When the mold cavity is filled with powder with a height of 2-4mm, spray a layer of dysprosium oxide with an average particle size of 2.5 microns through an argon spray gun The micropowder is reciprocally charged in this way, oriented in a magnetic field with a magnetic field strength of 2.0T, and pressed into shape to obtain a compact.

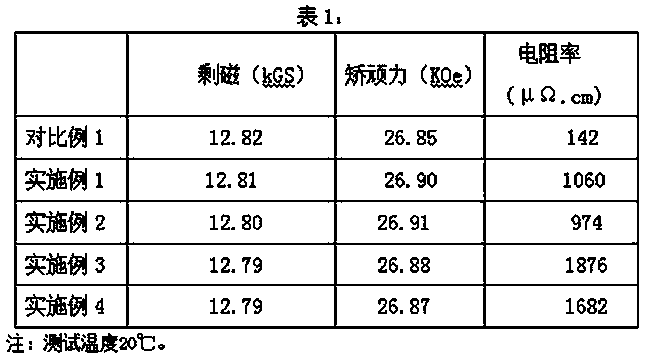

[0017] c. After isostatic pressing, the compact is placed in a vacuum sintering furnace, sintered at 1030℃×4hr and then air-cooled, and then tempered at 900℃×3hr and 520℃×5hr to obtain sintering magnet. The measured average magnetic performance inde...

Embodiment 2

[0023] a. Use the formula 40UH: Nd26.5Dy5.5B1.03Nb0.1Al0.1Col.0Cu0.1Ga0.1Fe65.57 (mass percentage content) to smelt NdFeB alloy cast pieces, and use hydrogen crushing and jet milling to make powder Process, prepare raw material powder with an average particle size of 3.2 microns for use.

[0024] b. Add 310 grams into the hopper to make a 40*40*25 (orientation size) block size blank. When the cavity is filled with powder with a height of 2-4mm, spray a layer of dysprosium fluoride with an average particle size of 2.5 microns. The micropowder is reciprocally charged in this way, oriented in a magnetic field with a magnetic field strength of 2.0T, and pressed into shape to obtain a compact.

[0025] c. After isostatic pressing, the compact is placed in a vacuum sintering furnace, sintered at 1030℃×4hr and then air-cooled, and then tempered at 900℃×3hr and 520℃×5hr to obtain sintering magnet. The measured average magnetic performance indexes of the prepared magnet and the meas...

Embodiment 3

[0027] a. Use the formula 40UH: Nd26.5Dy5.5B1.03Nb0.1Al0.1Col.0Cu0.1Ga0.1Fe65.57 (mass percentage content) to smelt NdFeB alloy cast pieces, and use hydrogen crushing and jet milling to make powder Process, prepare raw material powder with an average particle size of 3.2 microns for use.

[0028] b. Feed the material into the charging hopper to make a blank of 40*40*25 (orientation size) square size. When the mold cavity is filled with powder with a height of 2-4mm, spray a layer of fine alumina powder with an average particle size of 2.5 microns. After the reciprocating loading is completed, the orientation and compression molding are performed in a magnetic field with a magnetic field strength of 2.0T to obtain a compact.

[0029] c. After isostatic pressing, the compact is placed in a vacuum sintering furnace, sintered at 1030℃×4hr and then air-cooled, and then tempered at 900℃×3hr and 520℃×5hr to obtain sintering magnet. The measured average magnetic performance indexes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com