Microwave sintering preparation method of high purity silicon nitride ceramic lift tube for low-pressure casting

A silicon nitride ceramic and low-pressure casting technology is applied in the microwave sintering preparation of high-purity silicon nitride ceramic risers for low-pressure casting, and the microwave sintering preparation of inorganic non-metallic material products, and can solve problems such as unseen sintering production. , to achieve the effect of improving microwave absorption capacity, large volume, and uniformity of heating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

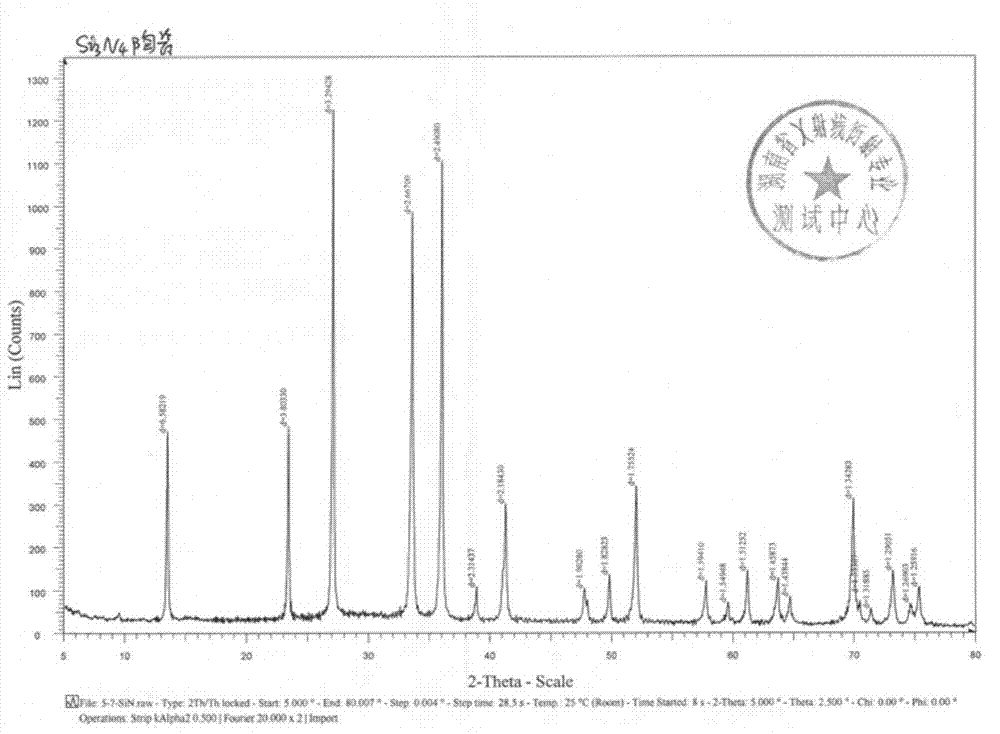

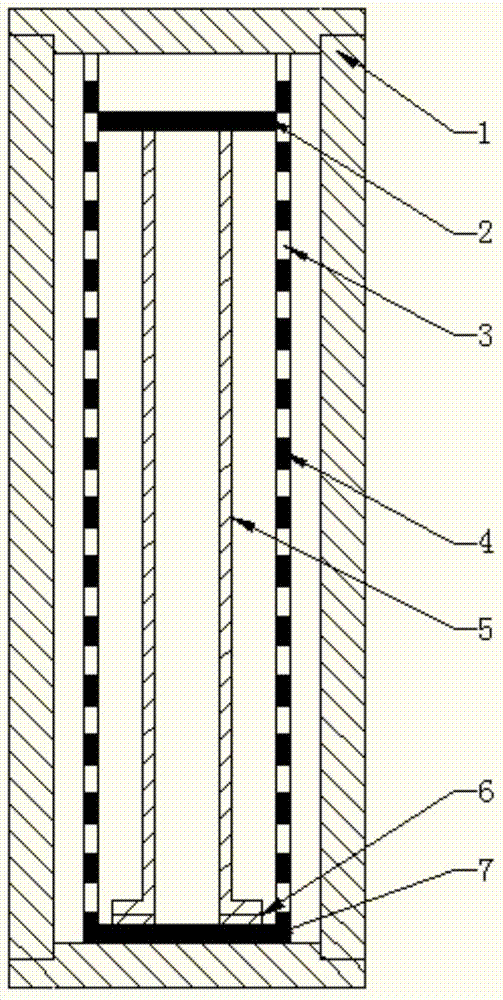

Embodiment 1

[0054] The high-purity silicon nitride powder and boron oxide accounting for 0.5% of the mass of the high-purity silicon nitride powder are put into a ball mill for wet ball milling, and the obtained slurry is dried and granulated to D 50 Particles of 50 μm to 70 μm are placed in a rubber mold and formed under high pressure in a cold isostatic press with a forming pressure of 100 MPa. The formed riser body is placed on a machine tool for trimming. The trimmed size is length 600mm, the inner diameter is 50mm, the outer diameter is 60mm, and the outer diameter of the flange is 100mm, and then the trimmed riser body is put into the bottom feeding microwave bell kiln for microwave sintering, and the body is placed under the same The microwave sintered structure is composed of alumina fiber cylinder, corundum mullite circular tube, graphite circular tube and graphite circular plate. The alumina fiber cylinder has a refractoriness of 1700°C and a density of 0.7g / cm 3 ; The corundu...

Embodiment 2

[0056] The high-purity silicon nitride powder and lithium hydroxide accounting for 1.0% of the mass of the high-purity silicon nitride powder are loaded into a ball mill for wet ball milling, and the obtained slurry is dried and granulated to D 50 Particles of 50 μm to 70 μm are placed in a rubber mold and molded under high pressure in a cold isostatic press with a molding pressure of 120 MPa. The formed riser body is placed on a machine tool for trimming. The trimmed size is length 900mm, the inner diameter is 100mm, the outer diameter is 130mm, and the outer diameter of the flange is 180mm, then the trimmed riser body is put into the bottom feeding microwave bell kiln for microwave sintering, and the body is placed under the same The pad firing ring of different materials, the microwave sintered structure is composed of alumina fiber cylinder, corundum mullite tube, graphite tube and graphite disc, among which the alumina fiber cylinder has a refractoriness of 1700°C and a de...

Embodiment 3

[0058] The high-purity silicon nitride powder and lithium carbonate accounting for 1.5% of the mass of the high-purity silicon nitride powder are loaded into a ball mill for wet ball milling, and the obtained slurry is dried and granulated to D 50 Particles of 50 μm to 70 μm are placed in a rubber mold and formed under high pressure in a cold isostatic press with a forming pressure of 150 MPa. The formed riser body is placed on a machine tool for trimming. The trimmed size is length 1200mm, the inner diameter is 150mm, the outer diameter is 180mm, and the outer diameter of the flange is 220mm, and then the trimmed riser body is placed in a bottom-feed microwave bell kiln for microwave sintering. The pad sintered powder of the same material, the microwave sintered structure is composed of alumina fiber cylinder, corundum mullite tube, graphite tube and graphite disc, among which the alumina fiber cylinder has a refractoriness of 1700°C and a density of 0.7g / cm 3 The corundum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com