Polyvinyl chloride composite material with microwave absorption property and preparation method thereof

A composite material and polyvinyl chloride technology, applied in the field of polyvinyl chloride composite material and its preparation, can solve the problems of unfavorable industrial production, lengthening the cycle of composite material preparation, long curing time, etc., and achieves good microwave absorption performance and light weight. , the effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

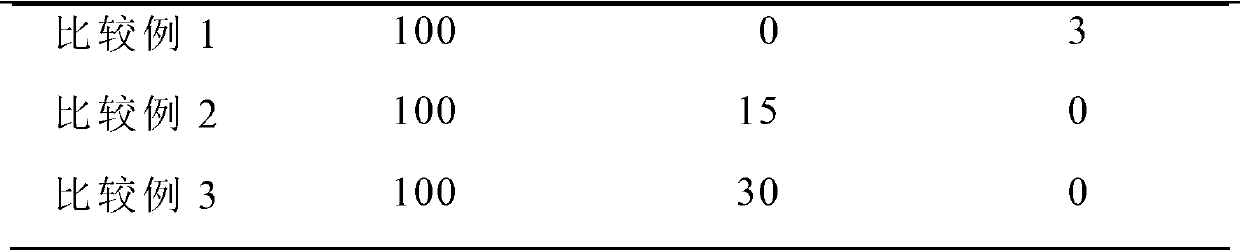

Examples

Embodiment 2

[0026] The degree of polymerization of the PVC resin described in Example 2 is 1200, the described thermal stabilizer is lead sulfate tribasic, the described lubricant is polyethylene oxide, and the described processing aid is methyl acrylate. The plasticizer mentioned is diethyl phthalate,

Embodiment 3

[0027] The degree of polymerization of the PVC resin described in embodiment 3 is 1300, and described thermostabilizer is organic tin maleate, and described lubricant is zinc stearate, and described processing aid is ethyl acrylate , the plasticizer is di-n-octyl phthalate.

Embodiment 4

[0028] The degree of polymerization of the PVC resin described in embodiment 4 is 1500, and described thermal stabilizer is dibasic lead phosphite, and described lubricant is polyethylene oxide, and described processing aid is monostearic acid Glyceride, and the plasticizer is bis(2-ethylhexyl) phthalate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com