Light-emitting diode led growth method with p-type layer roughening

A technology of light-emitting diodes and growth methods, which is applied in the field of LED growth with roughened P-type layers, can solve problems affecting chip technology, device structure damage, etc., and achieve the effect of improving light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

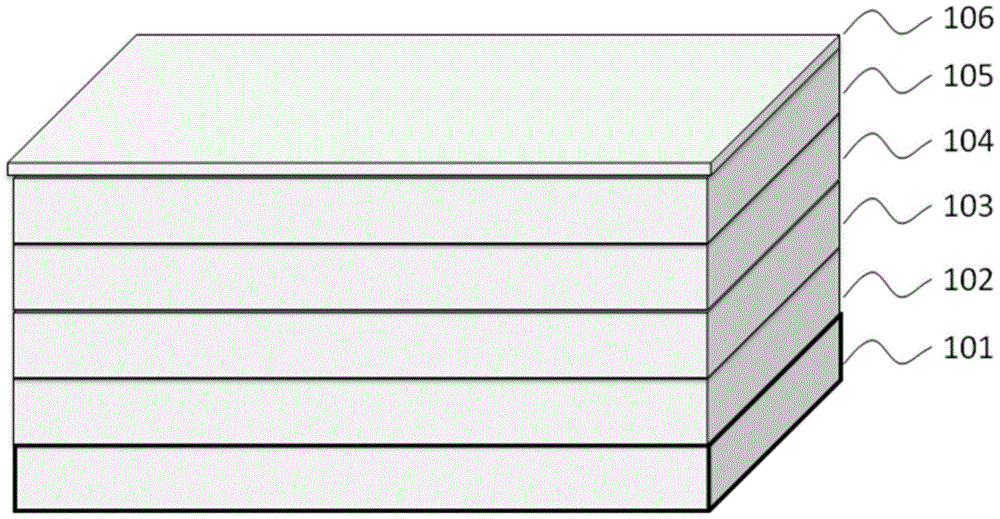

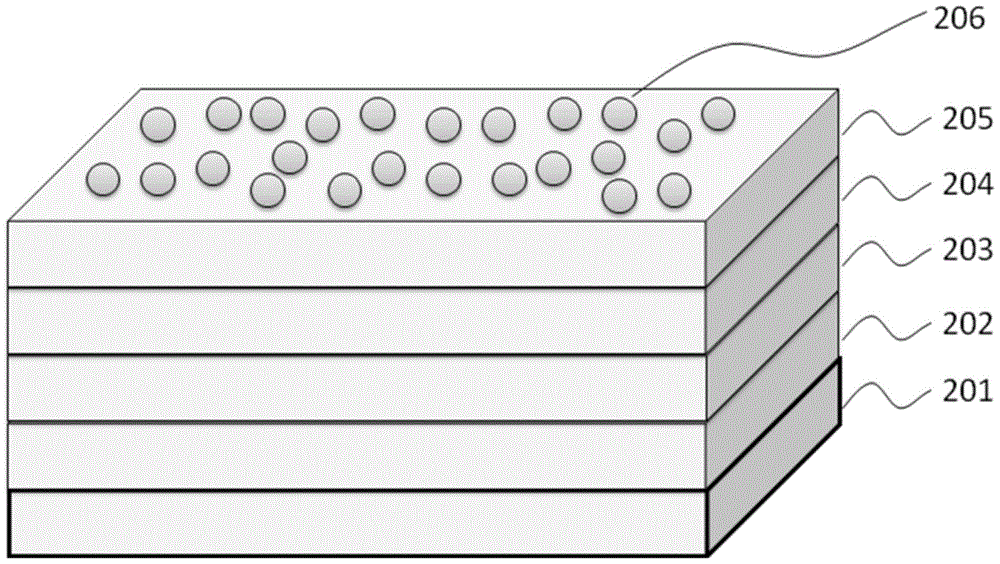

[0059] GaN blue LED with roughened P-type layer (using GaN spherical crystal as roughening medium)

[0060] 1. On the Veeco M℃VD K465I machine, use a patterned sapphire substrate. When the surface temperature of the substrate material (Figure 2201 layer) rises to about 530℃, keep the growth pressure at 500 Torr. Pass trimethylgallium (60ml / min) and ammonia gas (NH 3 )50l / min for 3 minutes, trimethylgallium and NH 3 At this temperature, it decomposes and reacts chemically to form an amorphous buffer growth layer with a thickness of 20nm.

[0061] 2. Increase the temperature of the reaction chamber to 1000°C. At this time, the buffer layer undergoes decomposition and polymerization to form uniformly distributed nucleation islands. Then, on this basis, the pressure is maintained at 500 Torr, and trimethylgallium (200ml / min) and NH 3 50l / min reaction for 30 minutes. This growth process can make the crystal nucleus islands grow and merge, without doping any impurities to form a...

specific Embodiment 2

[0068] GaN blue light LED with roughened P-type layer (using AlN spherical crystal as roughening medium)

[0069] 1. On the Veeco M℃VD K465I machine, use a graphic sapphire substrate, when the substrate material ( figure 2 When the surface temperature of the 201 layer) rises to about 530° C., the growth pressure is maintained at 500 Torr. Pass trimethylgallium (60ml / min) and ammonia gas (NH 3 )50l / min for 3 minutes, trimethylgallium and NH 3 At this temperature, it decomposes and reacts chemically to form an amorphous buffer growth layer with a thickness of 20nm.

[0070] 2. Increase the temperature of the reaction chamber to 1000°C. At this time, the buffer layer undergoes decomposition and polymerization to form uniformly distributed nucleation islands. Then, on this basis, the pressure is maintained at 500 Torr, and trimethylgallium (200ml / min) and NH350l / min reacted for 30 minutes. This growth process can make the crystal nucleus islands grow and merge, without doping...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com