Metal-based high-temperature insulation layer and preparation method thereof

A high-temperature insulation, metal-based technology, applied in metal layered products, metal material coating processes, chemical instruments and methods, etc. Poor adhesion and other problems, to reduce the possibility of cracking and shedding, improve insulation performance, and reduce leakage channels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

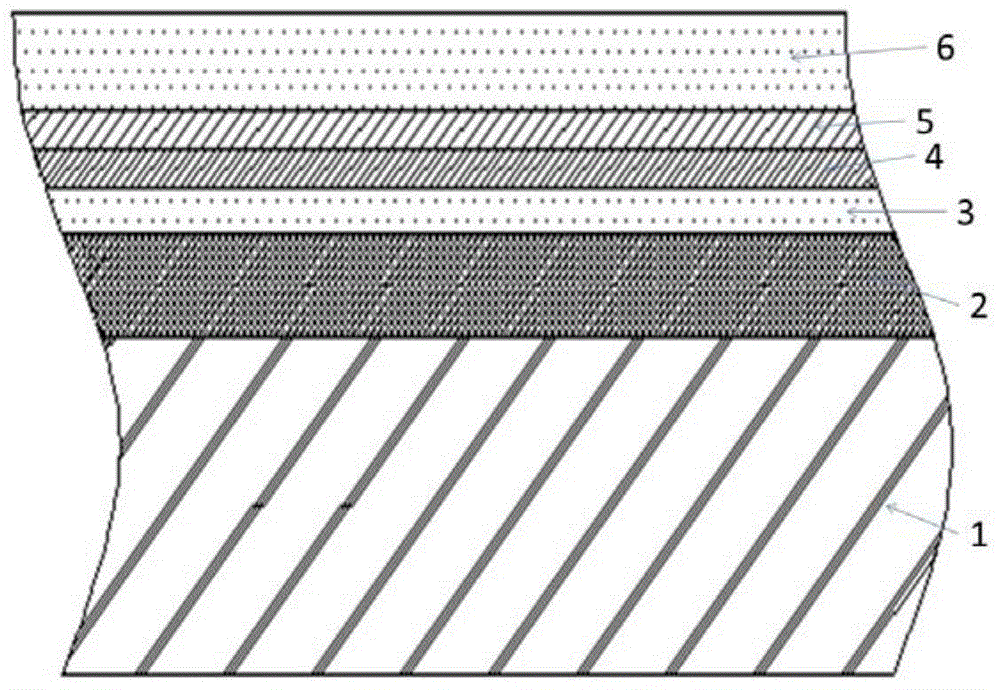

[0032] A method for preparing a metal-based high-temperature insulating layer, comprising the following steps:

[0033] A. Surface treatment of the substrate: use (length×width×thickness) 30×95×5 nickel (Ni)-based alloy as the substrate. Scratch; Then use acetone, ethanol and deionized water to clean the surface of the substrate in turn, and dry it with nitrogen after cleaning for later use;

[0034] B. Preparation of NiCrAlY alloy transition layer: place the cleaned Ni-based alloy substrate in a vacuum of 5×10 -3 In Pa vacuum (i.e. background vacuum) environment, NiCrAlY alloy is used as the target material, and argon gas with a purity of 99.99% (volume percentage) is introduced as the sputtering medium. Air pressure) is under the condition of 0.35Pa, adopts the method for DC magnetron sputtering to deposit a 12 μ m thick NiCrAlY alloy transition layer on the Ni-based alloy substrate;

[0035] C.α-Al 2 o 3 Layer preparation: the composite substrate obtained in step B was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com