High-strength high-tenacity electro-gas welding agent core welding wire and preparation method

A technology of gas-electric vertical welding and flux-cored welding wire, which is applied to welding equipment, welding media, manufacturing tools, etc., can solve the problems of high procurement cost, long procurement cycle of welding materials in Japan, and increased construction cost of large oil storage tanks. Good welding process, stable arc and excellent impact performance at low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

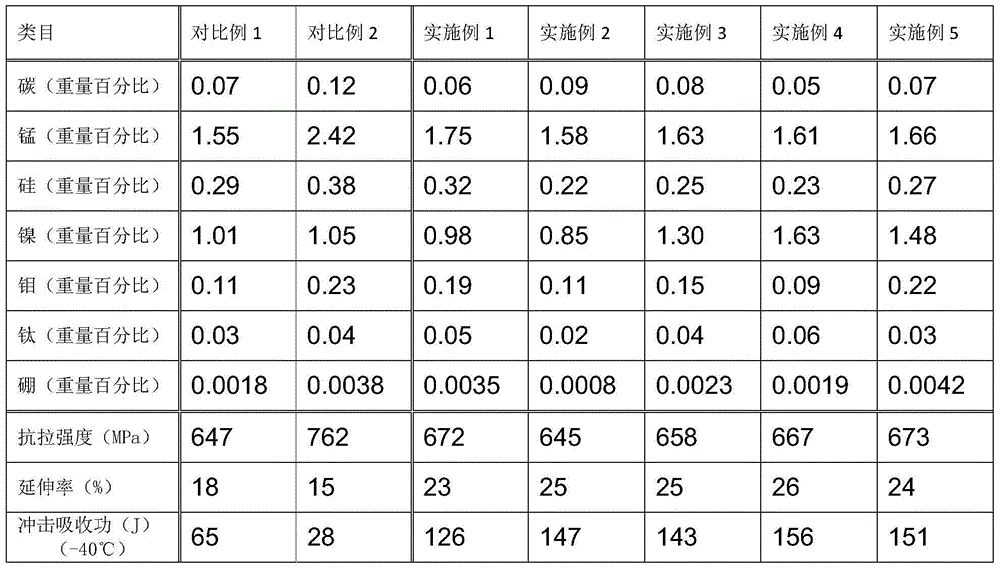

Examples

Embodiment 1

[0030] A method for preparing a high-strength and high-toughness gas-electric vertical welding flux-cored wire with a strength of 600 MPa, comprising the following process steps:

[0031] (1) Baking: First weigh 20 parts of calcium fluoride, 10 parts of sodium fluoride, 5 parts of barium fluoride, 10 parts of calcium carbonate, 7 parts of magnesium carbonate, 4 parts of barium carbonate, 8 parts of silicon dioxide, 5 parts of potassium oxide, 4 parts of titanium dioxide, 2 parts of sodium oxide, 2 parts of magnesium oxide, and 8 parts of calcium oxide are baked in high-temperature baking equipment at a baking temperature of 420°C;

[0032] (2) Mixing powder: Weigh 50 parts of silicon-manganese alloy, its model is FeMn64Si23, 20 parts of electrolytic manganese, 30 parts of ferrosilicon, its model is FeSi75, 5 parts of aluminum-magnesium alloy, and its ratio of aluminum to magnesium is 1:1, magnesium 5 parts of powder, 20 parts of ferromolybdenum, its model is FeMo60, 60 parts o...

Embodiment 2

[0038] A high-strength and high-toughness gas-electric vertical welding flux-cored wire and a preparation method thereof, the strength of which is at the level of 600MPa, comprising the following steps:

[0039] (1) Baking: First weigh 10 parts of calcium fluoride, 30 parts of sodium fluoride, 5 parts of barium fluoride, 5 parts of calcium carbonate, 10 parts of magnesium carbonate, 5 parts of barium carbonate, 3 parts of silicon dioxide, 2 parts of titanium dioxide, 10 parts of potassium oxide, 7 parts of sodium oxide, and 3 parts of magnesium oxide are baked in high-temperature baking equipment at a baking temperature of 380°C;

[0040] (2) Mixing powder: Weigh 80 parts of silicon-manganese alloy, whose model is FeMn62Si23, 10 parts of electrolytic manganese, 10 parts of ferrosilicon, whose model is FeSi75, 15 parts of aluminum-magnesium alloy, and its ratio of aluminum to magnesium is 1:1, magnesium 10 parts of molybdenum powder, 10 parts of ferromolybdenum, its model is Fe...

Embodiment 3

[0046]A high-strength and high-toughness gas-electric vertical welding flux-cored wire and a preparation method thereof, the strength of which is 600MPa, comprising the following process steps:

[0047] (1) Baking: First weigh 30 parts of calcium fluoride, 10 parts of sodium fluoride, 10 parts of calcium carbonate, 5 parts of magnesium carbonate, 5 parts of silicon dioxide, 3 parts of sodium oxide, 5 parts of magnesium oxide, and 2 parts are baked in high-temperature baking equipment, and the baking temperature is 400°C;

[0048] (2) Mixing powder: Weigh 60 parts of silicon-manganese alloy, its model is FeMn64Si23, 30 parts of electrolytic manganese, 15 parts of ferrosilicon, its model is FeSi75, 7 parts of aluminum-magnesium alloy, and its ratio of aluminum to magnesium is 1:1, magnesium 8 parts of powder, 15 parts of ferromolybdenum, its model is FeMo60, 80 parts of nickel powder, 25 parts of ferrotitanium, its model is FeTi30, 3 parts of ferroboron, its model is FeB2, 687 p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com