A kind of preparation method of filled type layered structure cemented carbide

A technology of cemented carbide and layered structure, which is applied in the field of preparation of filled layered structure cemented carbide, can solve problems such as poor wear resistance and poor toughness, achieve improved comprehensive performance, great social and economic benefits, and overcome Contradictory effects of toughness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

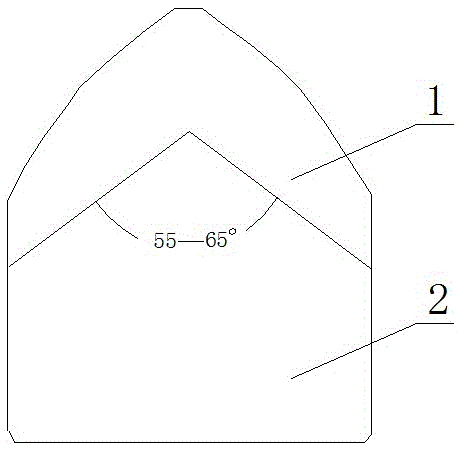

[0023] First, weigh the coarse-grained pellets with a particle size of 2.5-6.0 μm and the fine-grained pellets with a grain size below 1 μm according to the weight percentage of 35%: 65%, and then according to the ratio between the coarse-grained pellets and the fine-grained pellets Weight ratio relationship, determine the volume size and unit weight of the fine-grained granular material, and then press the fine-grained granular material into an angle of 55° o bullet-shaped semi-finished products. Press the fine-grained material into an angle of 55 o The purpose of the bullet-shaped semi-finished product is to ensure that the contact surface between the fine-grained pellets and the coarse-grained pellets must form a "V"-shaped interface, so as to ensure the joint quality of the subsequent coarse-grained pellets and fine-grained pellets. The pressure in the process of pressing the semi-finished product of the fine grain material is 600 kg / cm2. According to the total unit weig...

Embodiment 2

[0025] Firstly, weigh the low-cobalt material with a cobalt content of 6%-8% and the high-cobalt material with a cobalt content of 11%-20% according to the weight percentage of 30%:70%, and then according to the balance between the low-cobalt material and the high-cobalt material Weight ratio relationship, determine the volume and unit weight of the high-cobalt material, and then press the high-cobalt material into an angle of 60 o bullet-shaped semi-finished products. Press the high cobalt material into an angle of 60 o The purpose of the bullet-shaped semi-finished product is to ensure that the contact surface between the high-cobalt material and the low-cobalt material must form a "V"-shaped interface, so as to ensure the joint quality of the subsequent mutual pressing of the low-cobalt material and the high-cobalt material. The pressure during the pressing process of high-cobalt semi-finished products is 600 kg / cm2. According to the total unit weight of the product, put ...

Embodiment 3

[0027] First, weigh the primary tungsten carbide prepared by primary tungsten powder and the regenerated tungsten carbide after reduction processing of waste alloy according to the weight percentage of 40%: 60%, and then according to the weight ratio relationship between primary tungsten carbide and regenerated tungsten carbide, Determine the volume and single weight of the regenerated tungsten carbide, and then press the regenerated tungsten carbide into an angle of 65 o bullet-shaped semi-finished products. Press regenerated tungsten carbide into an included angle of 65 o The purpose of the bullet-shaped semi-finished product is to ensure that the contact surface between the regenerated tungsten carbide and the primary tungsten carbide must form a "V"-shaped interface, so as to ensure the joint quality of subsequent regenerated tungsten carbide and primary tungsten carbide. The pressure in the pressing process of recycled tungsten carbide semi-finished products is 600 kg / cm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com