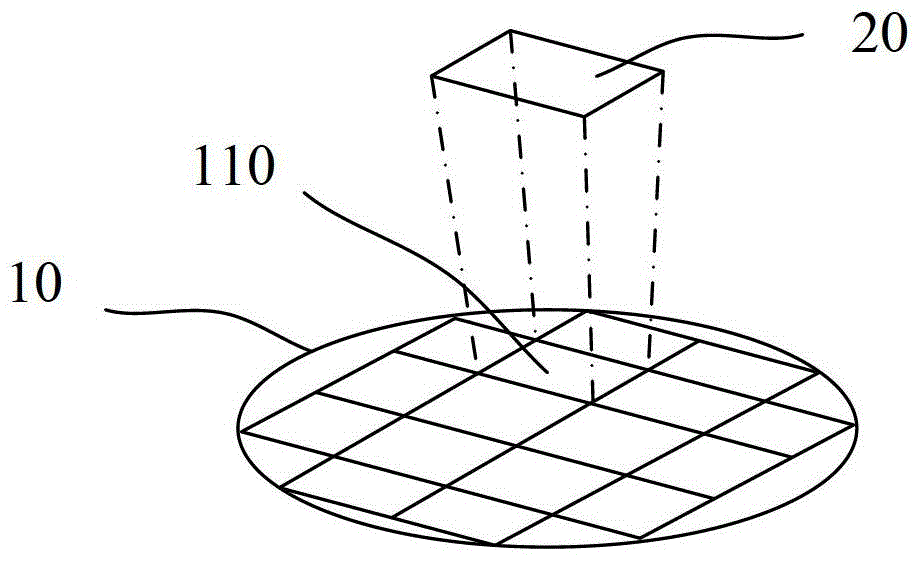

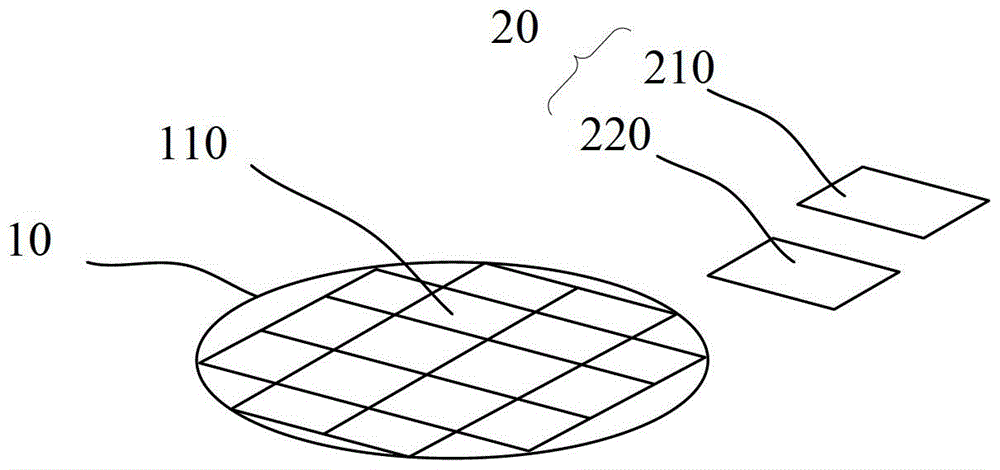

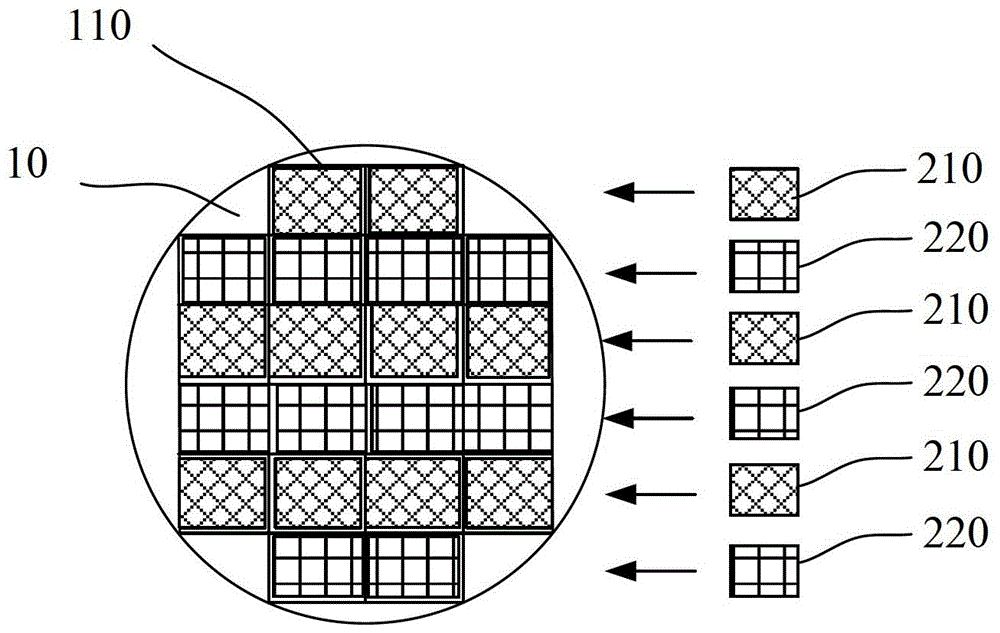

Method and lithography machine for judging consistency of overlay accuracy of lithography plate

A technique of engraving accuracy and photolithography, which is applied in the field of photolithography, can solve problems such as large impact, large manpower required, and long cycle time, and achieve low complexity, improve evaluation efficiency, and reduce evaluation difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the semiconductor manufacturing process, the photolithography process is a relatively critical process. The photolithography process includes steps such as pretreatment, spin-coating photoresist, soft baking, exposure, post-baking, and development. in:

[0020] 1) Substrate Pretreatment is used to change the properties of the wafer surface so that it can adhere firmly to the photoresist. The main method is to apply hexamethyldisilamine (HMDS): the wafer is heated to 120°C in a closed chamber, and the surface is sprayed with nitrogen to pressurize the mist of HMDS, so that the HMDS and the -OH bond on the wafer surface react. To remove water vapor and hydrophilic bond structure. Cool down on a cold plate after the reaction is complete.

[0021] 2) Spin coating photoresist (Spin coat), the uniformity and stability of the photoresist film can be improved by the spin coating method. The main substances in photoresist are resin, solvent, photosensitive agent and other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com