Recovery process and device for dehydrating agent for waste acetone generated in alginate fiber filament production

A seaweed fiber, recycling device technology, applied in the chemical industry, preparation of organic compounds, sustainable manufacturing/processing, etc., can solve the problems of high energy consumption and high equipment height, achieve low energy consumption, small footprint, energy consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

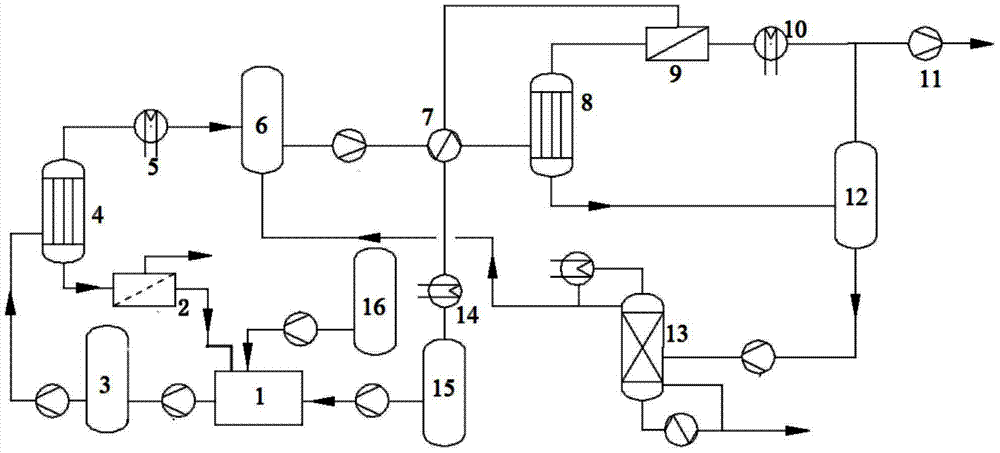

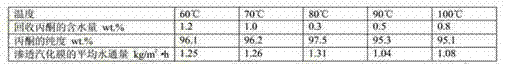

[0035] Flowchart of waste acetone dehydrating agent recovery process for medical seaweed fiber bandage production, such as figure 1 As shown, the process comprises the following steps: acetone is fed into the seaweed fiber silk dehydration tank 1 by the fresh acetone storage tank 16 to carry out the dehydration operation of the seaweed fiber, and then the waste acetone from the seaweed fiber silk dehydration tank 1 is sent into the waste acetone mother liquor The tank 3 is then fed into the front-stage evaporator 4 through the feed pump for heating and distillation. The temperature is controlled at 60°C, 70°C, 80°C, 90°C, and 100°C respectively. After the evaporated mother liquor is cooled by the condenser 5, It is mixed with the overhead distillate of the rectification tower 13 and stored in the acetone mother liquor tank 6. The controlled flow rate is 300kg / h and transported into the preheater 7 and the post-stage evaporator 8 for heating. The temperature at the top of the e...

Embodiment 2

[0041] Flowchart of waste acetone dehydrating agent recovery process for medical seaweed fiber bandage production, such as figure 1 As shown, the process includes the following steps: the waste acetone mother liquor from the seaweed fiber silk dehydration tank 1 is input into the front-stage evaporator 4 through the feed pump, and heated and distilled, the temperature is controlled at 80 ° C, and the evaporated mother liquor is passed through After the condenser 5 is cooled, it is mixed with the distillate at the top of the rectification tower 13 and stored in the acetone mother liquor tank 6. The controlled flow rate is 500kg / h and transported into the preheater 7 and the post-stage evaporator 8 for heating. The temperature at the top of the evaporator is controlled at 70°C. The acetone vapor with a water content of 7wt.% from the top of the evaporator enters the pervaporation membrane separator 9 for separation. The separation unit is a membrane separator composed of 8 set...

Embodiment 3

[0044] Flowchart of waste acetone dehydrating agent recovery process for medical seaweed fiber bandage production, such as figure 1 As shown, the process comprises the following steps: the waste acetone mother liquor from the seaweed fiber silk dehydration tank 1 is input into the waste acetone mother liquor tank 3 through the feed pump, and then the feed pump is used to enter the front-stage evaporator 4 for heating and distillation. Respectively controlled at 80°C, the evaporated mother liquor is cooled by the condenser 5, mixed with the overhead distillate of the rectification tower 13 and stored in the acetone mother liquor tank 6, and the flow rate is controlled to be 500kg / h to be transported into the preheater 7 and the rear Heating in the stage evaporator 8, the top temperature of the evaporator is controlled at 105°C. The acetone vapor with a water mass percentage of 8wt.% coming out from the top of the evaporator enters the pervaporation membrane separator 9 for sep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

| Mwco | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com