Metal casting blank continuous manufacturing device and method capable of providing pressure casting function

A technology for manufacturing devices and manufacturing methods, which is applied in the field of metal casting billets, can solve the problems of metal casting billets such as looseness, uneven composition, and coarse grains, and achieve the goal of improving the degree of grain refinement, increasing density, and increasing elongation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

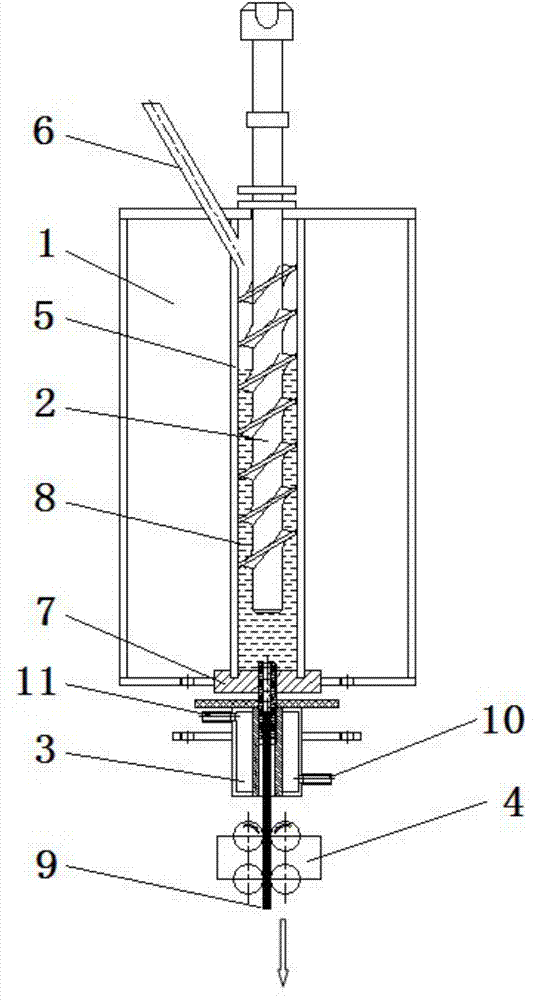

Embodiment 1

[0033] A continuous manufacturing method for Φ16mm copper rod billet, first start the melting furnace 1, heat the furnace chamber 6 to 1200°C, start the screw 2 and adjust the speed to 20r / min, and connect the water inlet 10 and water outlet 11 of the crystallizer 3 Open it, let the cooling water start to flow, slowly add the pure copper particles with a composition of 99.99% from the feeding port 6, the added pure copper particles will melt rapidly and advance towards the crystallizer under the action of the screw, when the material is added to the screw When about three-quarters of the position, start the tractor 4, pull the pure copper rod billet 9 at a speed of 40mm / min, increase the rotating speed of the screw rod 2 to 100r / min at the same time, adjust the water inlet 10 in the crystallizer 3 size to make the towing process smooth. The pure copper pellets are replenished from the feeding port 6 in good time to realize the continuous production of high-quality pure copper ...

Embodiment 2

[0035] A continuous manufacturing method of Φ8mm aluminum alloy billets, first start the melting furnace 1, heat the furnace chamber 6 to 800°C, start the screw 2 and adjust the speed to 10r / min, and connect the water inlet 10 and the water outlet of the crystallizer 3 11 is opened to make the cooling water start to flow, and slowly add the aluminum alloy melt with the grade of 3003 from the feeding port 6, and the added aluminum alloy melt is pushed towards the crystallizer under the action of the screw, when the material is added to the four corners of the screw When the position is about three-thirds, start the tractor 4 to pull the aluminum alloy rod blank 9 at a speed of 200mm / min, and increase the speed of the screw 2 to 500r / min at the same time, adjust the size of the water inlet 10 in the crystallizer 3, Make the towing process smooth. The 3003 aluminum alloy melt is replenished from the feeding port 6 in good time to realize the continuous production of high-quality ...

Embodiment 3

[0037] A continuous manufacturing method of Φ60×3mm brass tube billet, first start the melting furnace 1, heat the furnace chamber 6 to 1050°C, start the screw 2 and adjust the speed to 20r / min, and connect the water inlet 10 of the crystallizer 3 and Open the water outlet 11 to make the cooling water start to flow, slowly add the brass particles with the brand name H65 from the feeding port 6, and the added brass particles will be melted quickly and pushed towards the crystallizer under the action of the screw, when the material is added When the three-quarters position of the screw rod is reached, the tractor 4 is started, and the pure copper rod billet 9 is pulled at a speed of 20mm / min, and the rotating speed of the screw rod 2 is increased to 100r / min at the same time, and the water inlet 10 in the crystallizer 3 is adjusted. The size makes the traction process smooth. Replenish the brass pellets from the feeding port 6 in good time to realize the continuous production of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com