Silver nano column cluster array, as well as preparation method and application thereof

A technology of silver nanorods and pillar arrays, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as excessive silver nanorod spacing, high SERS activity, and preparation methods that cannot be solved. Achieve the effect of good uniformity and repeatability, good uniformity and repeatability, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The concrete steps of preparation are:

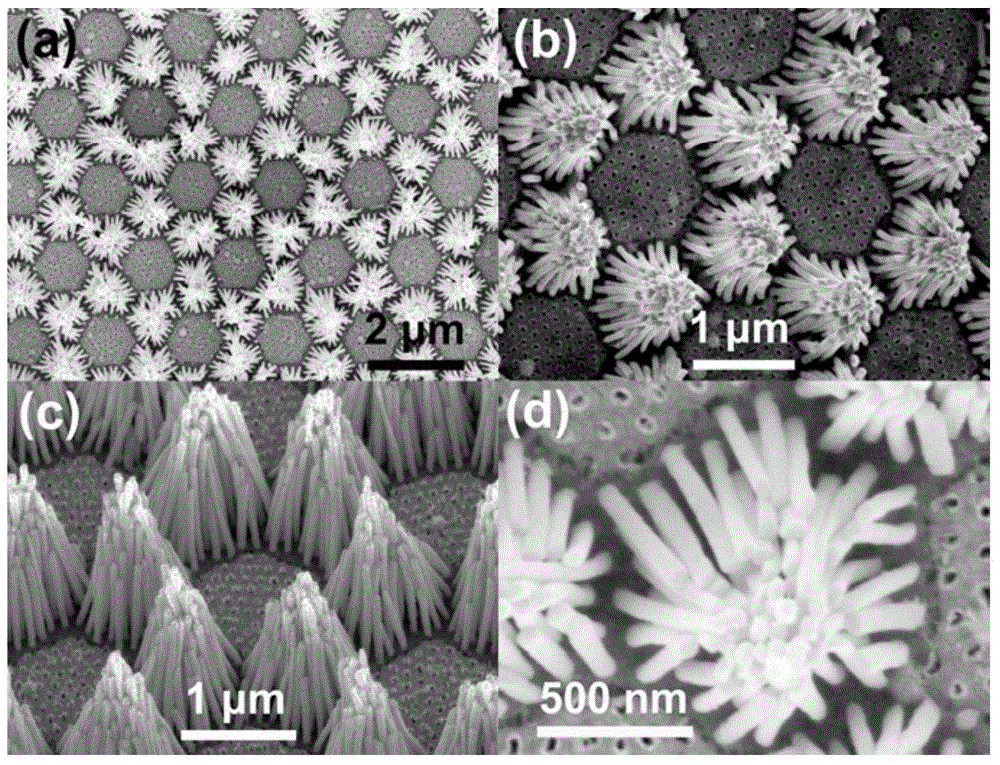

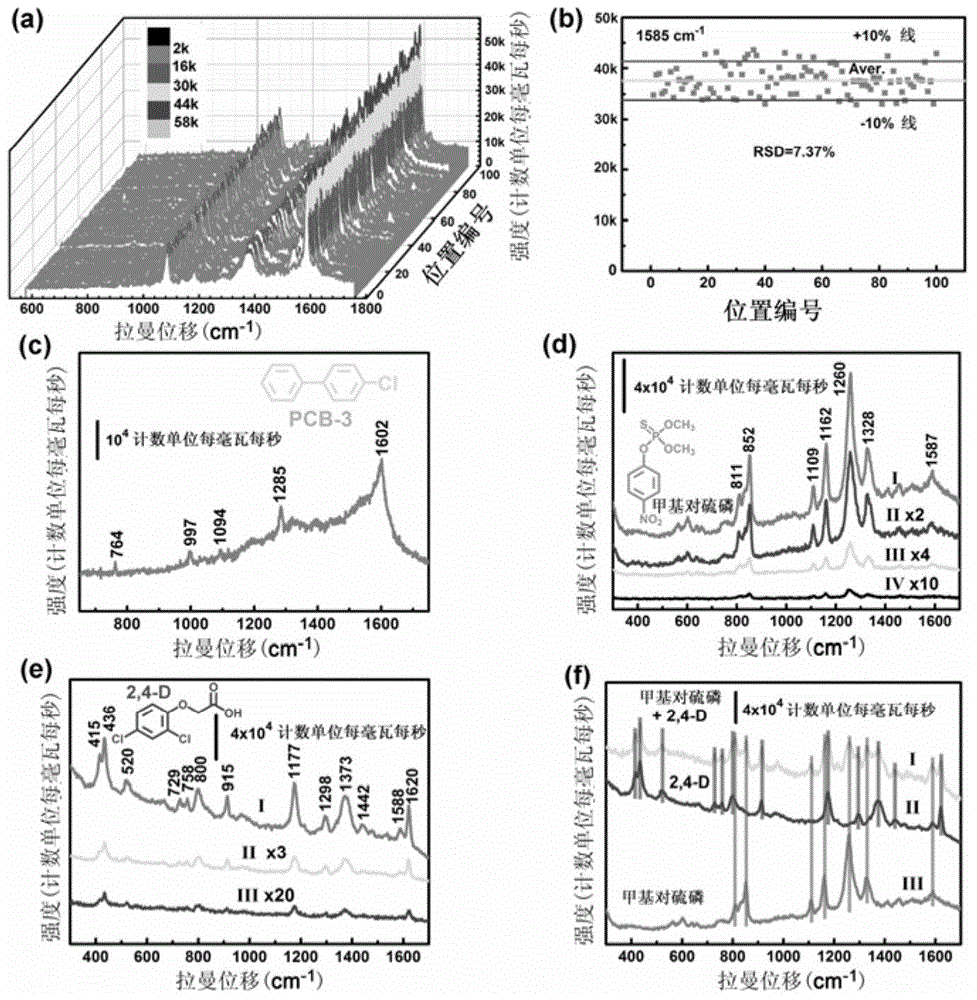

[0038] Step 1, first transfer the single-layer crystal template with a ball diameter of 1.5 μm to the surface of a through-hole alumina template with a hole diameter of 55 nm; wherein, the single-layer crystal template is a polystyrene colloidal sphere template (or a silica microsphere template ) to get the composite template. A gold film with a thickness of 50 nm is sputtered on one side of the composite template with a single-layer crystal template to obtain a composite template covered with a gold film on one side.

[0039] Step 2, first place the composite template with a gold film on one side in the silver electrolyte, at a current density of 70 μA / cm 2 Electrodeposited at a constant current for 15 minutes to obtain a composite template with a gold film on one side and silver nanopillars in the holes. Then use chemical (or physical) method to remove the single-layer crystal template in the composite template; wherein, the ...

Embodiment 2

[0042] The concrete steps of preparation are:

[0043] Step 1, first transfer the single-layer crystal template with a ball diameter of 1.8 μm to the surface of a through-hole alumina template with a pore diameter of 60 nm; wherein, the single-layer crystal template is a polystyrene colloidal sphere template (or a silicon oxide microsphere template ) to get the composite template. A gold film with a thickness of 53 nm was sputtered on one side of the composite template with a single-layer crystal template to obtain a composite template covered with a gold film on one side.

[0044] Step 2, first place the composite template with a gold film on one side in the silver electrolyte, at a current density of 130μA / cm 2 Electrodeposited at a constant current for 14 minutes to obtain a composite template with a gold film on one side and silver nanopillars in the holes. Then use chemical (or physical) method to remove the single-layer crystal template in the composite template; where...

Embodiment 3

[0047] The concrete steps of preparation are:

[0048] Step 1, first transfer the single-layer crystal template with a ball diameter of 2 μm to the surface of a through-hole alumina template with a hole diameter of 65 nm; wherein, the single-layer crystal template is a polystyrene colloidal sphere template (or a silica microsphere template) , to get the composite template. A gold film with a thickness of 55 nm is sputtered on the side of the composite template with a single-layer crystal template to obtain a composite template covered with a gold film on one side.

[0049] Step 2, first place the composite template with a gold film on one side in the silver electrolyte, at a current density of 190μA / cm 2 Electrodeposited at a constant current for 13 minutes to obtain a composite template with a gold film on one side and silver nanopillars in the holes. Then use chemical (or physical) method to remove the single-layer crystal template in the composite template; wherein, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com