Method of manufacturing semiconductor device using polycrystalline silicon annealed by solid-state laser

A technology of polycrystalline silicon thin film and amorphous silicon thin film, which is used in semiconductor/solid state device manufacturing, electrical components, circuits, etc., can solve the problems of insufficient quality of materials and high processing temperature, and achieve low cost, high quality and uniformity. and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in detail as follows with reference to accompanying drawing:

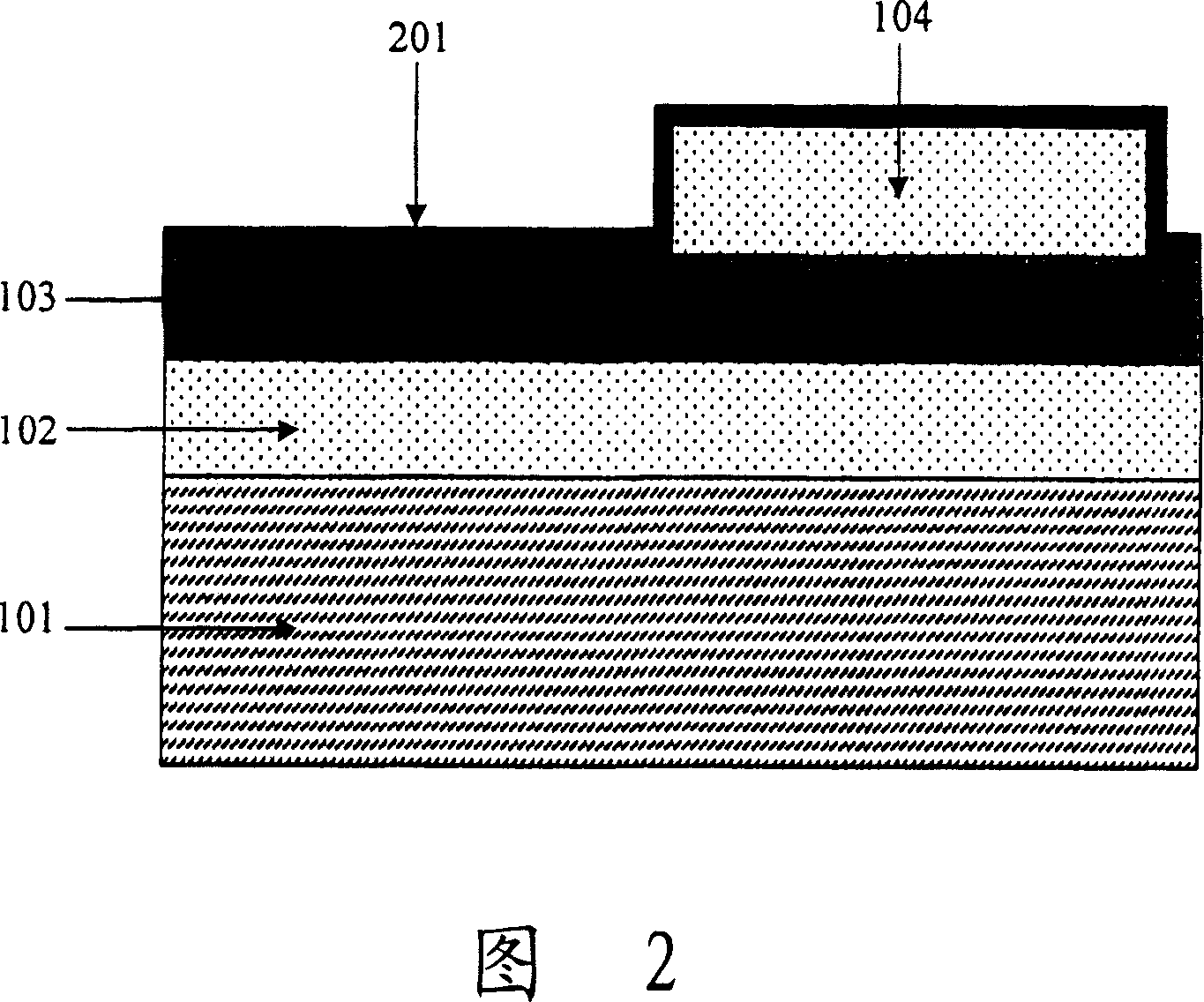

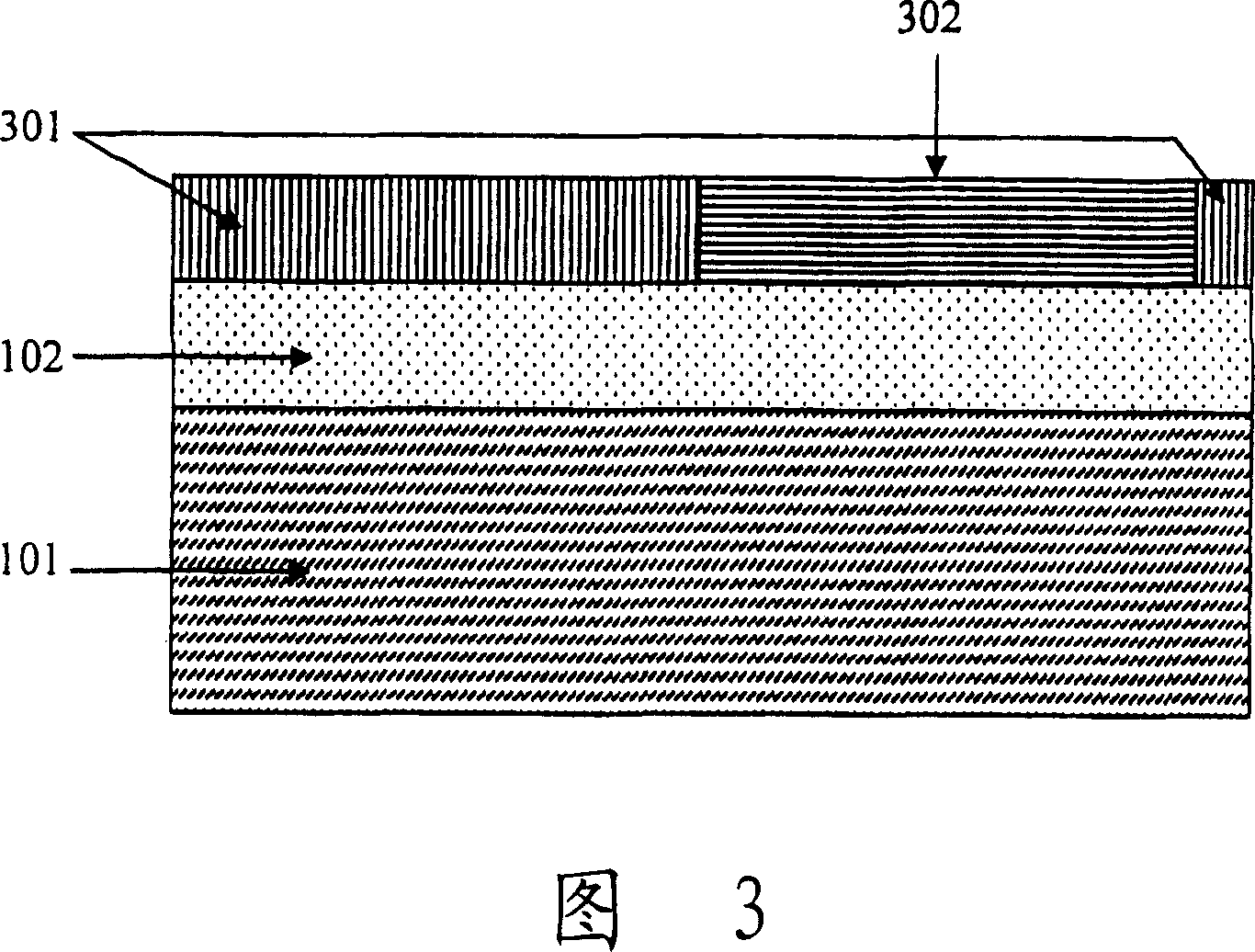

[0038] The method of fabricating a semiconductor device using metal-induced crystallization of polysilicon annealed by a solid-state laser is described below, see FIGS. 1-9.

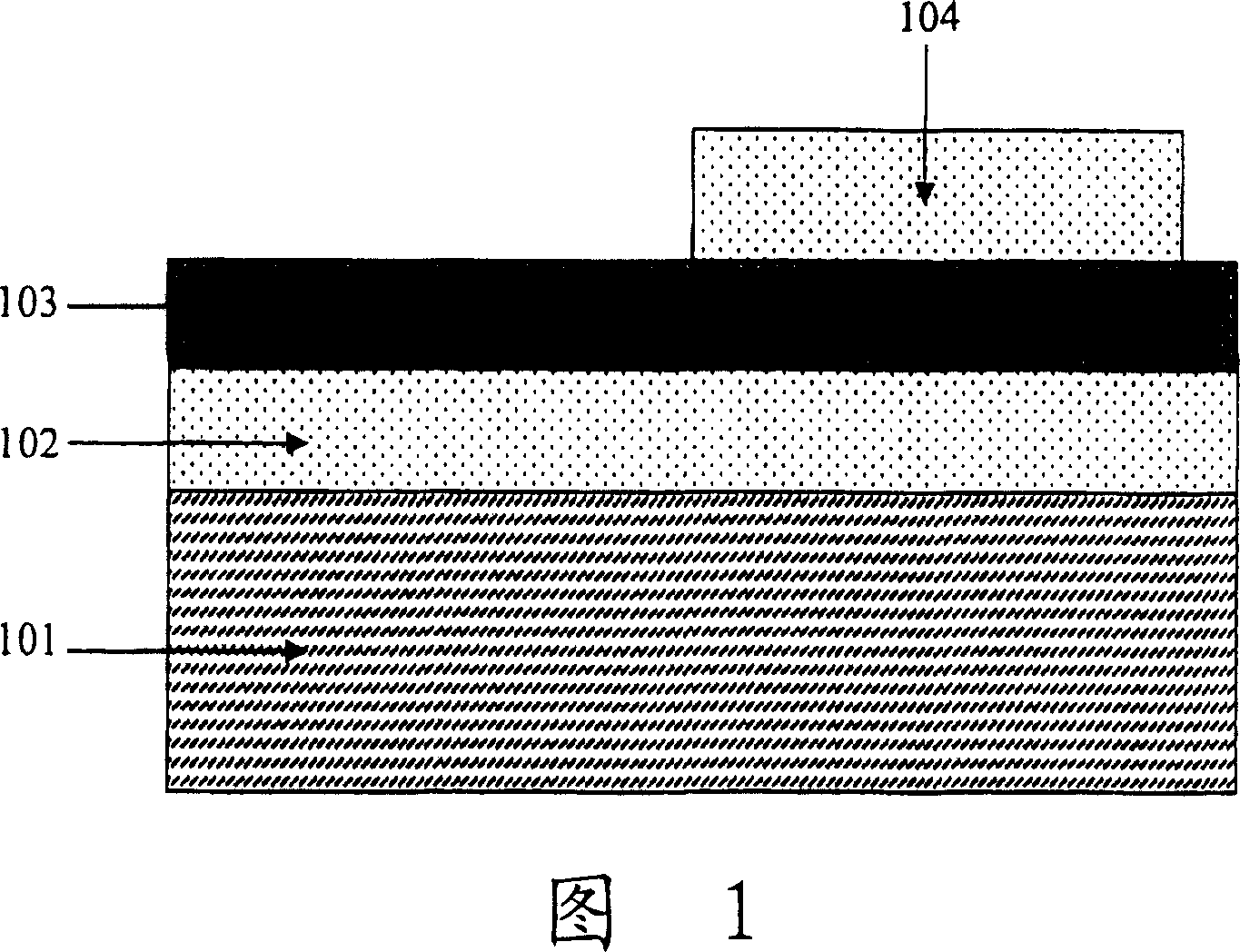

[0039] FIG. 1 : A schematic cross-sectional view of an amorphous silicon film 103 and a mask layer 104 deposited on a substrate 101 covered with an insulating layer 102 .

[0040] The substrate can be one of high temperature polymer, glass, stainless steel, polycrystalline silicon or single crystal silicon containing prefabricated conventional integrated circuits.

[0041] The transition layer can withstand processing at a processing temperature higher than 650° C. for a long time, including but not limited to silicon oxide, silicon oxynitride, and silicon nitride.

[0042] An amorphous silicon film 103 with a thickness of 10 nanometers to 3 micrometers is formed at a low temperature of 150°C-600°C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com