Piercing plug of steel pipe and preparation method thereof

A technology of perforated plugs and steel pipes, applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., to achieve the effects of long service life, good wear resistance, and improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

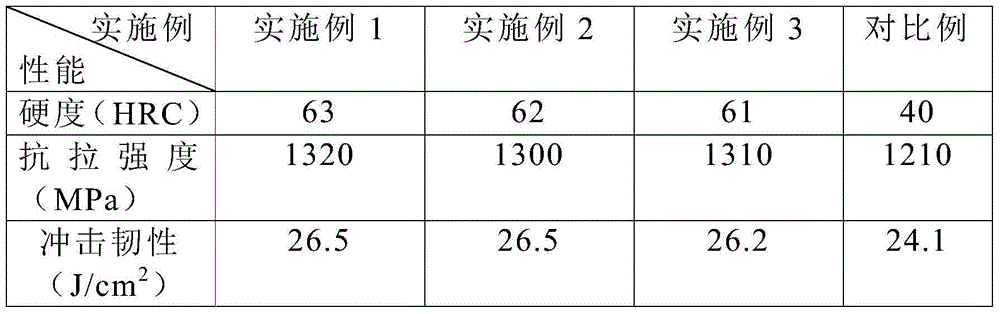

Embodiment 1

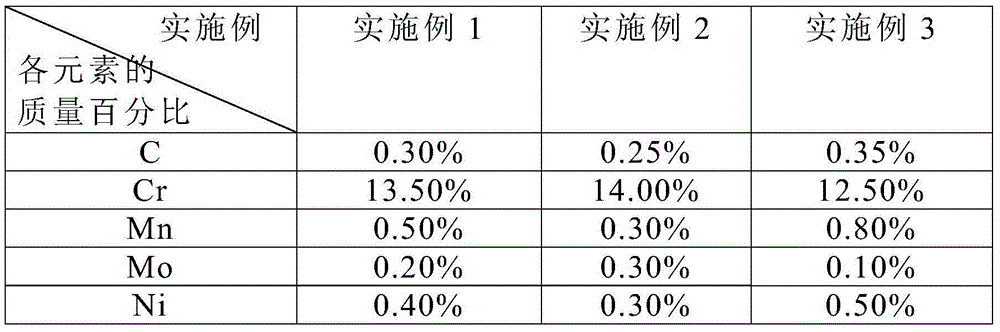

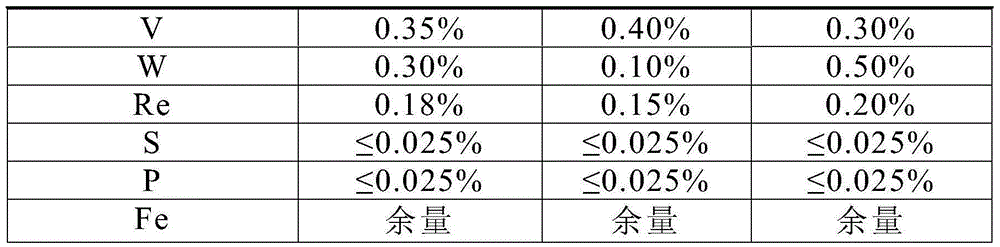

[0037] Raw material preparation: Prepare raw materials according to the composition elements and mass percentages of the steel pipe perforated plug described in Example 1 in Table 1;

[0038] Forging: smelting and pouring the prepared raw materials to process them into the desired shape; the pouring temperature is 1450°C;

[0039] Annealing heat treatment: heat the processed steel pipe perforated plug to 920°C for annealing, keep it warm for 3 hours after annealing, and then take it out of the furnace at 330°C and air cool to obtain the finished product of steel pipe perforated plug;

[0040] Quenching and tempering: Heat the above-mentioned steel pipe piercing plug first finished product to 1140°C for quenching, heat it for 1-3 hours, then cool it to room temperature with oil, and then perform tempering treatment. After cooling to 60°C for 3 hours, perform a second tempering treatment at 530°C to obtain a steel pipe perforated plug.

Embodiment 2

[0042] Raw material preparation: prepare raw materials according to the composition elements and mass percentages of the steel pipe perforated plug described in Table 1, Example 2;

[0043] Forging: smelting and pouring the prepared raw materials, and processing them into the desired shape; the pouring temperature is 1420°C;

[0044] Annealing heat treatment: heat the processed steel pipe perforated plug to 930°C for annealing, keep it warm for 2 hours after annealing, and then take it out of the furnace at 350°C and air cool to obtain the finished product of steel pipe perforated plug;

[0045] Quenching and tempering: heat the above-mentioned steel pipe piercing plug first finished product to 1120°C for quenching, keep warm for 3 hours and then oil cool to room temperature, and then temper. The first tempering temperature is 530°C, keep warm for 2 hours, and cool After reaching 60°C, carry out the second tempering treatment at 520°C to obtain the steel pipe perforated plug. ...

Embodiment 3

[0047] Raw material preparation: prepare raw materials according to the composition elements and mass percentages of the steel pipe perforated plug described in Example 3 of Table 1;

[0048] Forging: smelting and pouring the prepared raw materials to process them into the desired shape; the pouring temperature is 1460°C;

[0049] Annealing heat treatment: heat the processed steel pipe perforated plug to 880°C for annealing, keep it warm for 4 hours after annealing, and then take it out of the furnace at 300°C and air cool to obtain the finished product of steel pipe perforated plug;

[0050] Quenching and tempering: Heat the above-mentioned steel pipe piercing plug first finished product to 1160°C for quenching, heat it for 1 hour and then cool it to room temperature with oil, and then perform tempering treatment. After reaching 60°C, perform a second tempering treatment at 540°C to obtain a steel pipe perforated plug.

[0051] The comparative example is the steel pipe perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com