Wide-distribution polyisocyanate-coupled multi-arm star random butadiene-styrene copolymer and preparation method thereof

A technology of polyisocyanate and random copolymer, which is applied in the field of multi-arm star-shaped random styrene-butadiene copolymer and its preparation, can solve the problem that white carbon black cannot be effectively melted in the rubber compound, raw rubber has low elastic memory, dynamic Issues such as heat generation and reduced rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

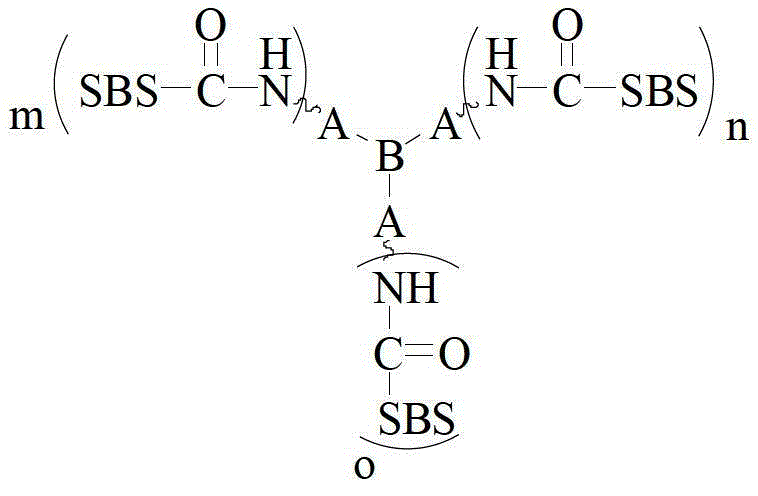

Method used

Image

Examples

Embodiment 1

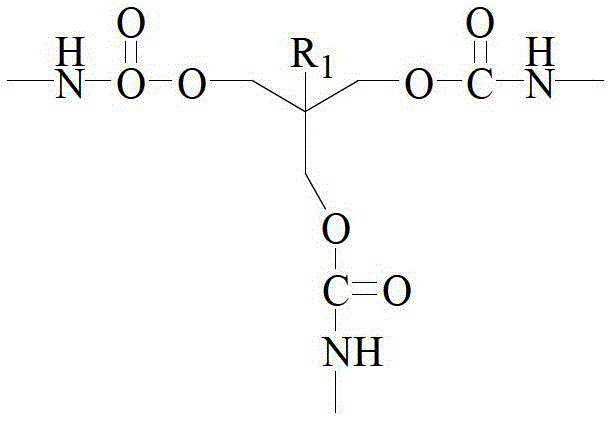

[0092] (1) In a clean and dry 1000mL three-necked bottle under the protection of nitrogen, add anhydrous 425mL toluene, TMP80g, TDI290.58g respectively, at this time TMP / TDI=1:3.02 (mass ratio), in After stirring at a constant temperature of 75-80°C for 6-8 hours, the measured solid content was 49.6wt%, and the concentration of isocyanate was 0.83mol / L. The average functionality of the adduct molecule contains 3 -NCO.

[0093] (2) Add anhydrous 425mL toluene, TMP80g and TDI239.60g respectively in a clean and dry 1000mL three-necked bottle under the protection of nitrogen gas. At this time, TMP / TDI=1:2.52 (mass ratio), constant temperature After stirring for 6-8 hours at 75-80°C, the measured solid content was 50.3wt%, and the concentration of isocyanate was 0.74mol / L. The average functionality of the adduct molecule contains 4 -NCO.

[0094] (3) Add anhydrous 425mL toluene, TMP80g and TDI219.87g respectively in a clean and dry 1000mL three-necked bottle under the protection ...

Embodiment 2

[0100] Steps (1) to (6) are the same as in Example 1,

[0101]Take 2mL of chemically pure TDI with a mass content of 99%, 15mL of the prepolymer in (1), 20mL of the prepolymer in (2), 35mL of the prepolymer in (3), 15mL of the prepolymer in (4), Inject 18mL of the prepolymer in (5) and 3mL of the prepolymer in (6) into a 100mL dried volumetric flask, then add an appropriate amount of toluene and mix well to make a polyisocyanate with an isocyanate concentration of 0.85mol / L. Isoacid coupling agent.

Embodiment 3

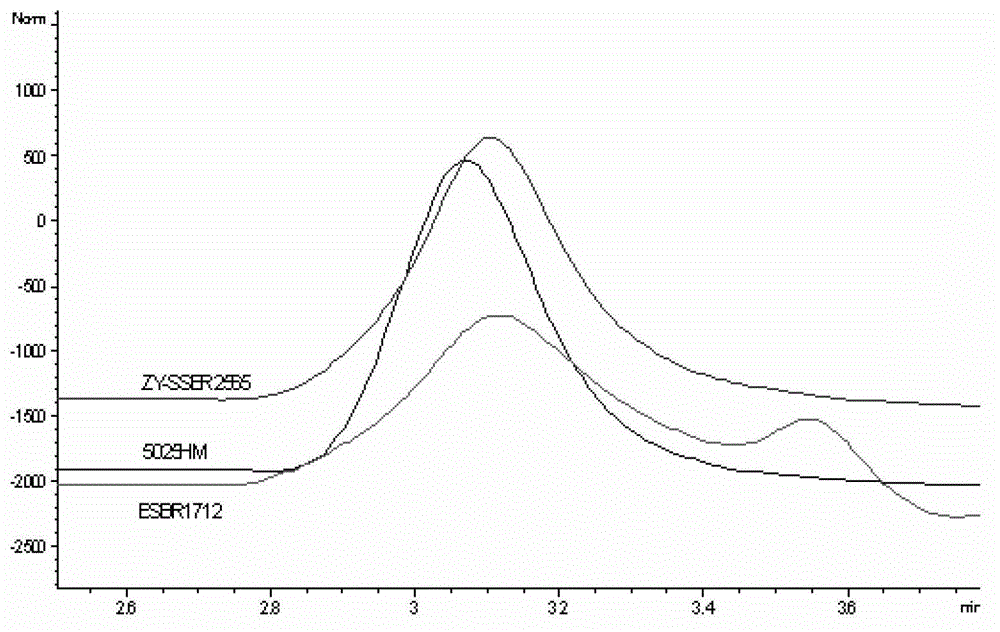

[0103] Under the protection of nitrogen, add 3.5 L of hexane-cyclohexane mixed solvent and 0.98 g of tetrahydrofurfuryl alcohol ethyl ether into a 5-liter polymerization kettle, start stirring within 40 minutes, and continuously and uniformly add 0.5 mol / L of n-butyl Lithium 13mL, and 132.5g of styrene and 397.5g of butadiene mixed monomers, the polymerization is carried out at 50-75°C, after the addition of the monomers, react for 25min, and then add the isocyanate concentration in Example 1. 9.5mL of 0.68mol / L prepolymer was subjected to coupling reaction, the coupling reaction temperature was 60-75°C, and the time was 25min. The obtained one-arm to eight-arm SSBR was filled with 198.1g of TDAE oil, condensed and dried to obtain SSBR filled Oil raw rubber, in which the number average molecular weight of single-arm polymer is 8.1×10 4 , the average number average molecular weight of the conjugate is 42×10 4 , molecular weight distribution index 2.23, vinyl content 74.6%, Moo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com