Semiconductor-wafer-surface-protective adhesive tape

An adhesive tape and semiconductor technology, which is applied in semiconductor devices, thin film/sheet adhesives, semiconductor/solid device manufacturing, etc. It can solve the problem of different adhesives, and it is difficult to improve the adhesion and prevent adhesives at the same time. , Peel off bad wafers and other problems, to achieve the effect of easy peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0143] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited to these examples.

[0144]

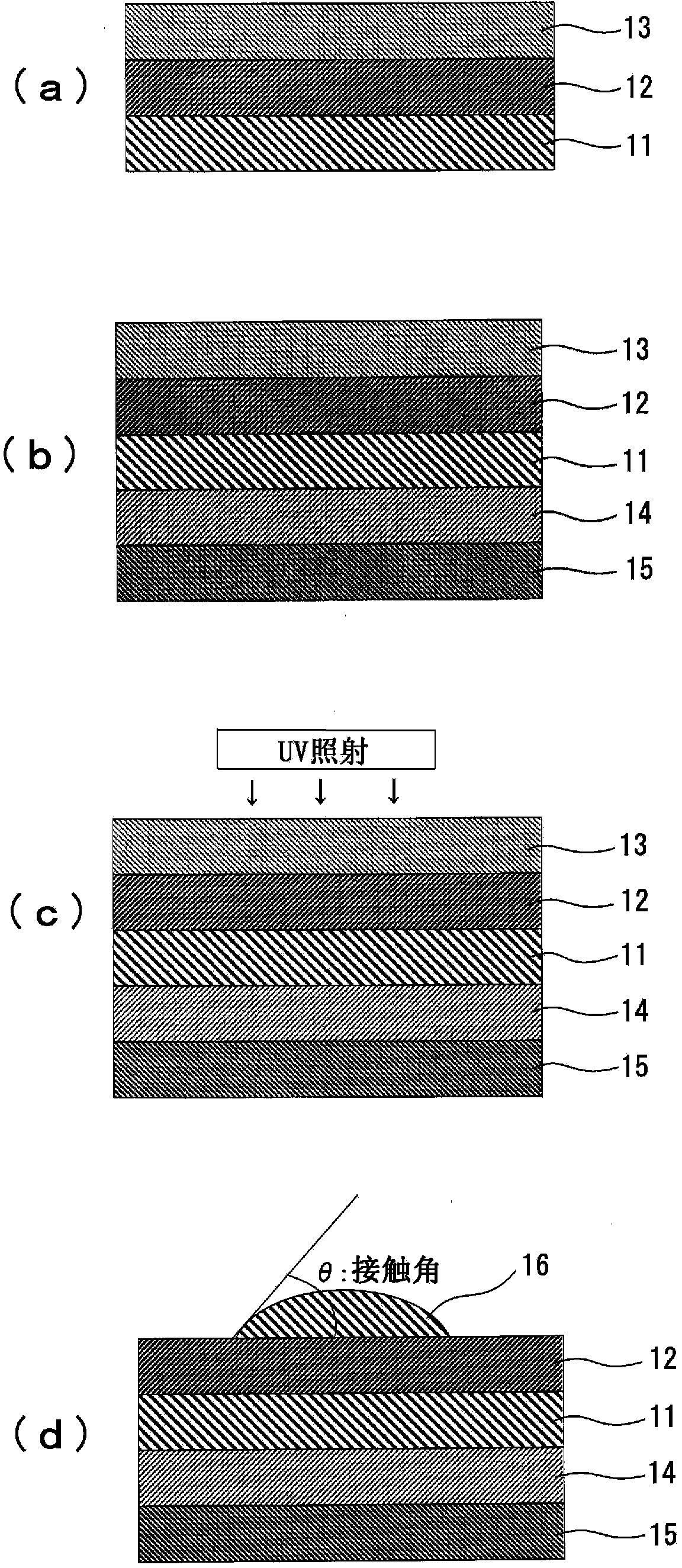

[0145] A polyoxyethylene alkylphenyl ether compound to which an allyl group was added and a polypropylene glycol compound were added as surfactants to deionized pure water, ammonium persulfate was added as a polymerization initiator, and the mixture was stirred while heating. Then, 17 mass parts of methyl methacrylate, 40 mass parts of n-butyl acrylate, 41 mass parts of 2-ethylhexyl acrylate, 2 mass parts of glycidyl methacrylate were added dropwise in the stirring solution, Further, stirring was continued to perform polymerization, and an acrylic emulsion pressure-sensitive adhesive composition was obtained.

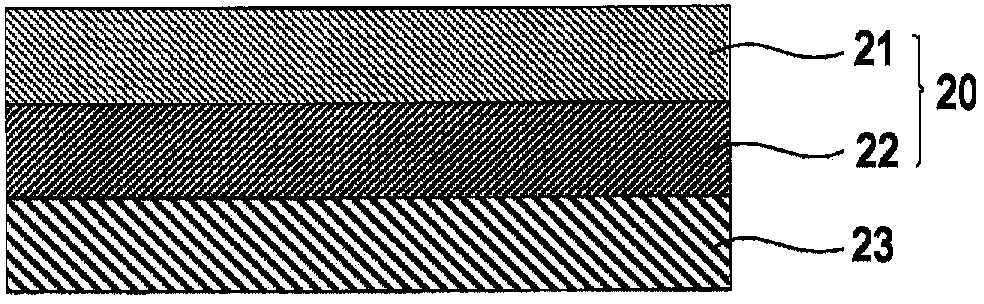

[0146] Coating and drying the adhesive composition on a polyethylene terephthalate (PET) release film of 25 μm, and laminating it on an ethylene-vinyl acetate copolymer (EVA) film having a thickness of 120...

Embodiment 2

[0148] In Example 1, the amount of methyl methacrylate was changed to 30 parts by mass, the amount of n-butyl acrylate was changed to 39 parts by mass, and the amount of 2-ethylhexyl acrylate was changed to 39 parts by mass. The adhesive tape for semiconductor wafer surface protection was produced similarly to Example 1 except having changed the film thickness of the adhesive layer into 48 micrometers.

Embodiment 3

[0150] In Example 1, the usage-amount of methyl methacrylate was changed to 16 parts by mass, the usage-amount of 2-ethylhexyl acrylate was changed to 40 parts by mass, and 2 parts by mass of methacrylic acid was further added, except Except for this, an acrylic emulsion pressure-sensitive adhesive composition was obtained in the same manner as in Example 1.

[0151]Except that the thickness of the EVA film was changed to 165 μm, and the film thickness of the adhesive layer was changed to 41 μm, this acrylic emulsion adhesive composition was made in the same manner as in Example 1 to produce an adhesive tape for semiconductor wafer surface protection. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com