PCB packaging structure based on light-weight miniature smt components

A technology of packaging structure and components, which is applied in the direction of printed circuits connected with non-printed electrical components, electrical connection printed components, printed circuit components, etc., which can solve the problems of electromagnetic radiation, short circuit with tin, poor welding, etc. problems, achieve the effect of reducing the risk of tin connection, preventing electromagnetic interference, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

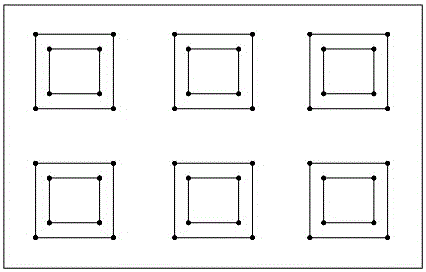

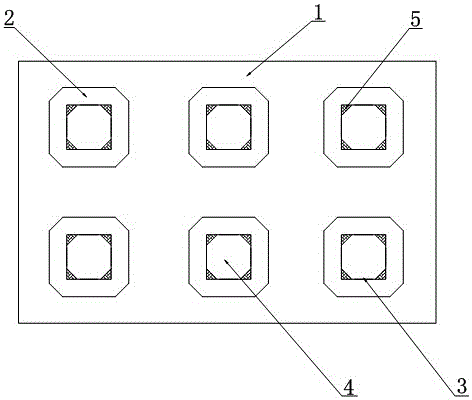

[0026] like figure 2 As shown, the present invention is mainly aimed at the PCB packaging of 0201, 0402, 0603, 0805, 1206, 1210 types of light-weight miniature SMT components, which include PCB substrate 1, SMT solder mask window 2 and SMT pad 4 . There are at least two windows in the SMT solder resist layer, which are straightened and evenly distributed on the PCB substrate 1 , and each window 2 in the SMT solder resist layer is provided with a square pad window 3 . The SMT pad 4 is arranged in the square pad opening 3, and the SMT pad 4 is a symmetrical octagonal structure formed by end-to-end connection of four equal long sides 41 and four equal hypotenuses 42, wherein the SMT pad The four long sides of 4 correspond to the four sides of the square pad opening 3 one by one, and the angle between the hypotenuse of the SMT pad and the long side is greater than 90°. The shape and arrangement of the outer edge of the window 2 in the SMT solder resist layer are the same as tho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com