Adhesive for anticorrosive paint for deep-sea oil-gas delivery steel tube outer walls and preparation method thereof

A technology of anti-corrosion coatings and adhesives, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of poor low-temperature impact of polypropylene, achieve good mechanical properties, long service life, and good processing sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

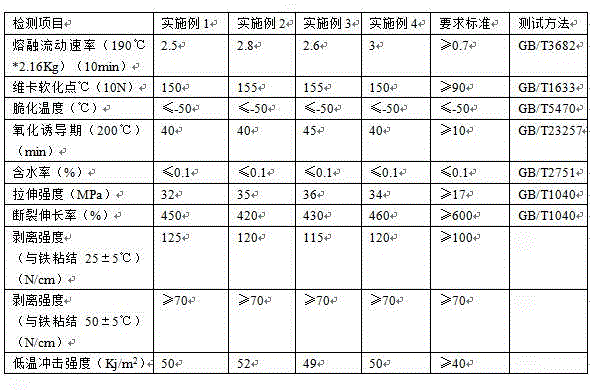

Examples

preparation example Construction

[0056] The preparation method of the adhesive used for the anti-corrosion coating on the outer wall of the steel pipe for deep-sea oil and gas transportation comprises the following steps:

[0057] a. Mix the raw materials and stir evenly, the stirring speed is 650~850 rpm;

[0058]b. Put the fully mixed raw materials in step a into the twin-screw extruder for mixing and plasticization; control the speed of the twin-screw extruder so that the mixture stays in the entire screw for 2 to 3 minutes, and set the temperature of each section in turn Set at 175°C, 180°C, 185°C, 190°C, 200°C, 200°C, 195°C, 185°C and 175°C, and set the speed of the pelletizer at 550~750 rpm during the pelletizing process;

[0059] c. The rod is water-cooled, and the water temperature in the water-cooling tank is set at 35~50°C;

[0060] d. Air-dried and granulated, extruded, granulated and packaged to obtain the adhesive.

Embodiment 1

[0063] (1) Raw materials:

[0064] Polypropylene: PPB4228

[0065] Functional polyolefin: EPDM rubber, ethylene-vinyl acetate copolymer

[0066] Reactive monomer: maleic anhydride

[0067] Graphene

[0068] Nano-CaCO 3

[0069] Initiator: di-tert-butyl peroxide

[0070] Nucleating agent: 1,3,2,4-bis(3-methyl-4-benzyl)sorbitol

[0071] Antioxidant: main antioxidant 1010, auxiliary antioxidant 168

[0072] According to the mass percentage, the ratio of the above raw materials is: 55% polypropylene, 30% functional polyolefin, 6% reactive monomer, 2% graphene, nano-CaCO 3 5%, initiator 0.1%, nucleating agent 0.4%, antioxidant 1.5% (of which the main antioxidant is 1%, and the secondary antioxidant is 0.5%).

[0073] (2) Preparation method:

[0074] 1. Mix the above raw materials and stir evenly, set the stirring speed at 650~850 rpm;

[0075] 2. Put the fully mixed raw materials in step 1 into the twin-screw extruder for mixing and plasticization; control the speed of th...

Embodiment 2

[0079] (1) Raw materials:

[0080] Polypropylene: PPB4228

[0081] Functional polyolefin: EPDM rubber, ethylene-vinyl acetate copolymer

[0082] Reactive monomer: maleic anhydride

[0083] Graphene

[0084] Nano-CaCO 3

[0085] Initiator: dibenzoyl oxide

[0086] Nucleating agent: 1,3,2,4-bis(3-methyl-4-benzyl)sorbitol

[0087] Antioxidant: main antioxidant 1010, auxiliary antioxidant 168

[0088] According to the mass percentage, the ratio of the above raw materials is: 60% polypropylene, 28% functional polyolefin, 4% reactive monomer, 1% graphene, nano-CaCO 3 5%, initiator 0.2%, nucleating agent 0.6%, antioxidant 1.2% (of which the main antioxidant 1010 is 0.8%, and the auxiliary antioxidant 168 is 0.4%).

[0089] (2) Preparation method:

[0090] 1. Mix the raw materials and stir evenly, set the stirring speed at 650~850 rpm;

[0091] 2. Put the fully mixed raw materials in step 1 into the twin-screw extruder for mixing and plasticization; control the speed of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com