Processing method of butanol and octanol waste alkaline solution

A treatment method and waste lye technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve high operating costs, low CODCr removal rate, large amount of resin, etc. problems, achieve significant environmental and economic benefits, high CODCr removal rate, and reduce wastewater discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

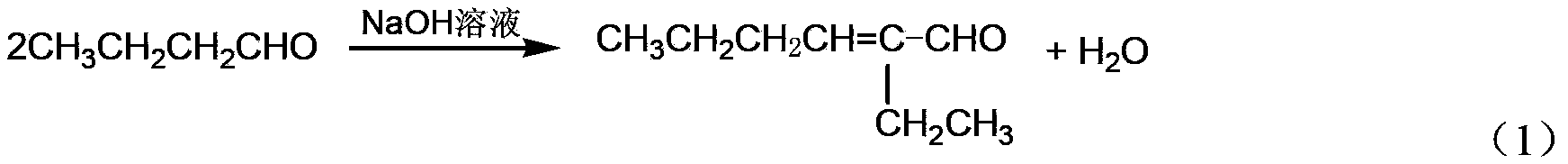

Method used

Image

Examples

Embodiment 1

[0040] Take 5L COD Cr The waste lye was 106312mg / L, and it was acidified with 98% concentrated sulfuric acid, adjusted to pH=3, the acidified solution was allowed to stand for 24 hours, the oil and water were separated, and the recovered oil was 96mL, and the COD of the clarified water phase was measured Cr It is 38521mg / L. The clarified water phase was concentrated by pervaporation membrane evaporation. The pervaporation membrane was a modified polyvinyl alcohol preferentially permeable membrane. The evaporation temperature was 45°C and the concentration ratio was 11 times. The concentrate and evaporation condensate were collected separately.

[0041] Evaporated condensate COD Cr It is 3548mg / L, and the flow rate is 1BV / h through the adsorption column filled with 100mL macroporous adsorption resin. When the adsorbed water volume is 30 times the resin volume, the effluent COD Cr It is 251mg / L, after that, the water COD Cr A rapid increase indicates that the resin has been a...

Embodiment 2

[0044] Take 5L COD Cr The waste lye was 106312mg / L, and it was acidified with 98% concentrated sulfuric acid to adjust the pH to 4.5. The acidified solution was left standing for 24 hours, and the oil and water were separated. The recovered oil was 95mL, and the COD of the clarified water phase was measured. Cr It is 39549mg / L. The clarified water phase was mixed with the desorption solution collected in Example 1, and the mixed solution was concentrated by pervaporation membrane evaporation. The pervaporation membrane was a Nafion membrane, the evaporation temperature was 45°C, and the concentration ratio was 13 times. The concentrates were collected separately and evaporate condensate. Evaporated condensate COD Cr It is 2362mg / L, with the flow velocity of 1BV / h, by the macroporous adsorption resin adsorption column adsorption treatment of embodiment 1 desorption regeneration, when the adsorption effluent volume is 32 times of the resin volume, the effluent COD Cr 245mg / L,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com