Method for removing calcium carbonate scales by using microbial extracellular carbonic anhydrase

A technology of carbonic anhydrase and calcium carbonate scale, applied in chemical instruments and methods, biological water/sewage treatment, complex/solubilizer treatment, etc., can solve problems such as environmental pollution and water eutrophication

- Summary

- Abstract

- Description

- Claims

- Application Information

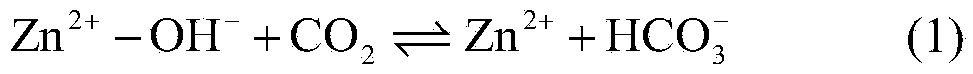

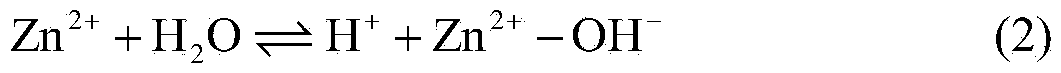

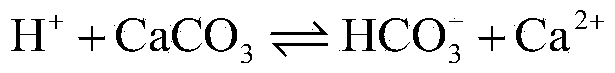

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 The method of the present invention removes calcium carbonate scale

[0030] 1) Preparation of bacterial agent: take an appropriate amount of cooling water from the circulating water system, and evenly coat it on the 60g / L calcium carbonate, 1μmol / LZnSO 4 On the beef extract peptone agar plate, place the plate at 34~37°C for 24h, pick out the grown colonies and use the streaking method for purification.

[0031] 2) Expansion culture: Inoculate the microorganism (Bacillus subtilis) purified in step 1) into LB liquid medium to expand the culture to a stable period, the culture temperature is 30±1°C, and the shaker speed is 120r / min.

[0032] 3) Extraction of carbonic anhydrase crude enzyme solution: Centrifuge the bacterial solution cultured in 2) at 4° C. and 5000 r / min for 10 minutes to remove cells. Add appropriate amount (NH 4 ) 2 SO 4 The solution saturation reached 70%, and after salting out at 4℃ for 12h, the protein was obtained by centrifugation at 8000r / min f...

Embodiment 2

[0036] Example 2 The method of the present invention removes calcium carbonate scale

[0037] 1) Preparation of bacterial agent: take an appropriate amount of cooling water from the circulating water system, and evenly coat it on the 60g / L calcium carbonate, 1μmol / LZnSO 4 On the beef extract peptone agar plate, place the plate at 34~37℃ for 24h, pick out the grown colonies and use the streaking method for purification.

[0038] 2) Expansion culture: Inoculate the microorganism (Bacillus subtilis) purified in step 1) into LB liquid medium to expand the culture to a stable period, the culture temperature is 30±1°C, and the shaker speed is 120r / min.

[0039] 3) Extraction of carbonic anhydrase crude enzyme solution: Centrifuge the cultured bacterial solution in 2) at 4° C. and 5000 r / min for 10 minutes to remove cells. Add appropriate amount (NH 4 ) 2 SO 4 The solution saturation reached 70%, and after salting out at 4℃ for 12h, the protein was obtained by centrifugation at 8000r / min fo...

Embodiment 3

[0042] Example 3 Treatment of scale formed in pipes of circulating water system in a chemical plant

[0043] Before treatment, the system fouled seriously, and the massive fouling closely adhered to the inner wall of the system, which caused blockage of the pipeline and reduced heat transfer efficiency. The microorganisms that secrete extracellular carbonic anhydrase were expanded and cultivated to an OD600nm value above 0.8, and the crudely extracted carbonic anhydrase was put into the circulating water system of the factory. After 10 days of normal operation, it was found that the massive scale on the inner wall of the system appeared loose and followed As the scouring of the circulating water falls off into the collecting tank, the pipe blockage has been improved, and the heat exchange efficiency of the system has also been improved. The scale deposited in the sump was collected, and it was found to be in powder form. The main components of the test result were carbonates such...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com