Dry manure two-phase anaerobic digestion system for pig farm

An anaerobic digestion system and technology of dry manure cleaning, applied in the field of two-phase anaerobic digestion system of dry manure cleaning in pig farms, can solve the problems of system efficiency reduction, bacterial activity reduction, loss, etc., and achieve comprehensive economic benefit improvement and reduction Subsequent processing load, solving the effect of large water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

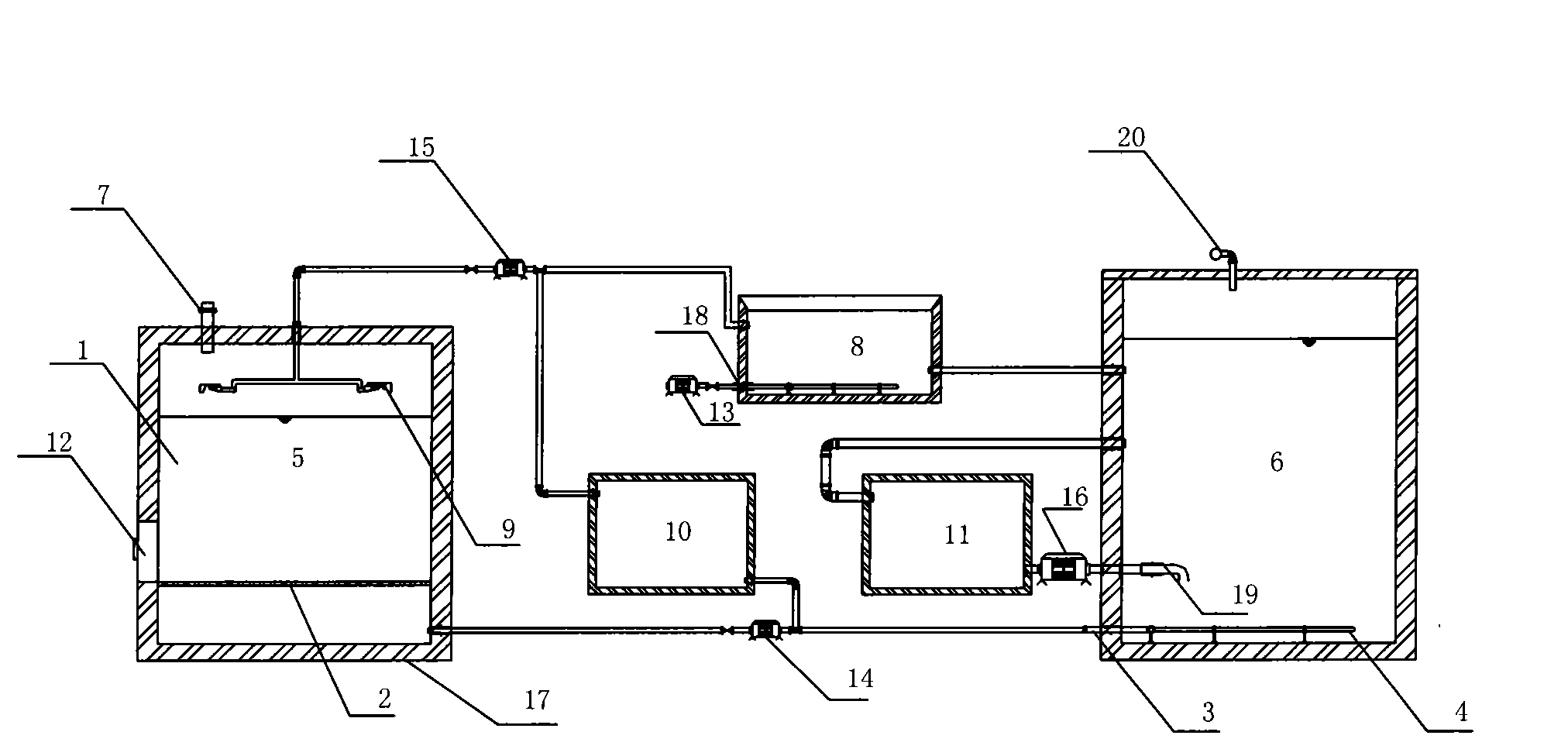

[0033] The invention provides a two-phase anaerobic digestion system for dry and clear manure in pig farms. The invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

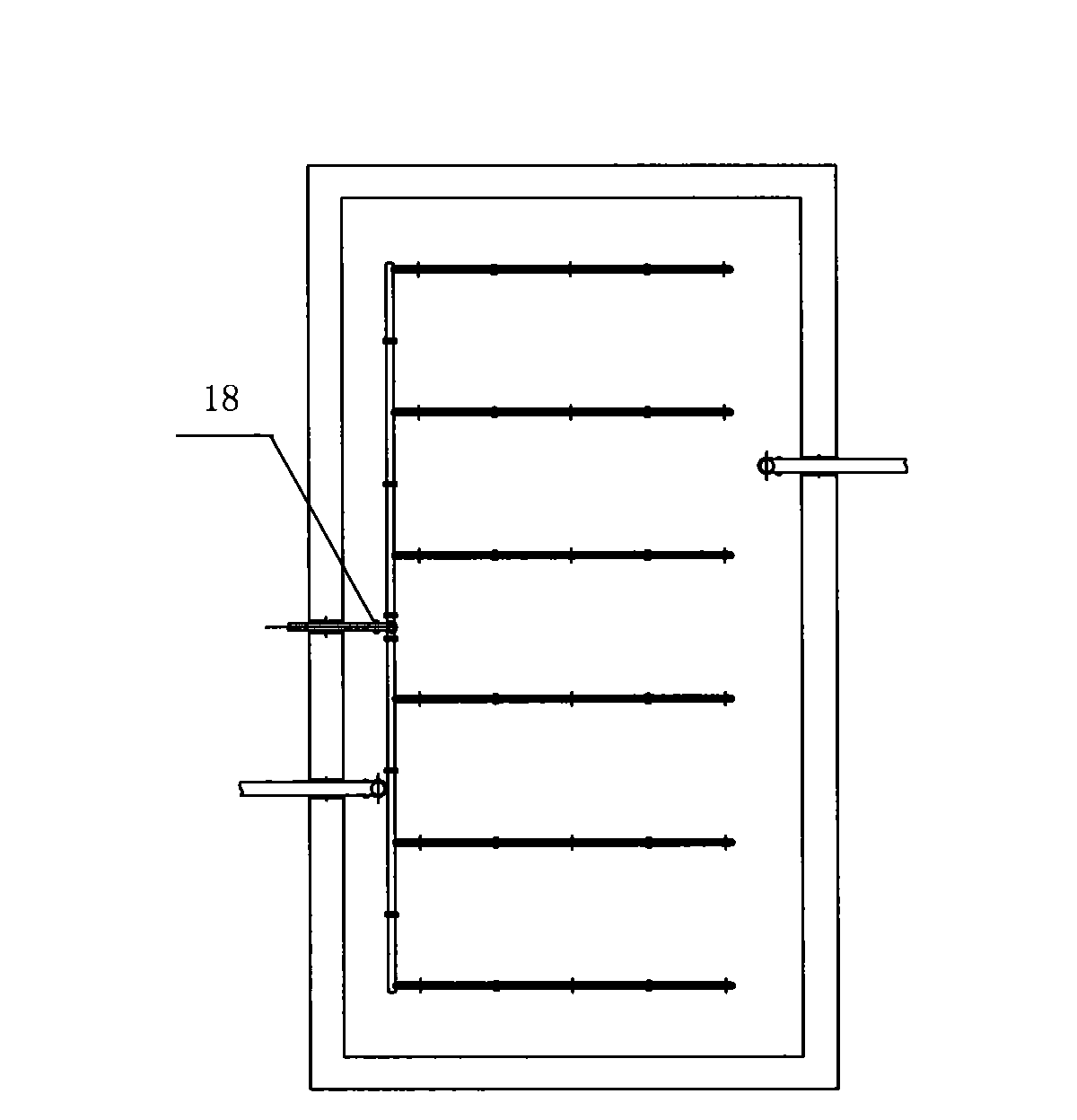

[0034] figure 1 is a system sectional view of the present invention. A two-phase anaerobic digestion system for dry and clear manure in pig farms, including a hydrolytic acidification reaction system, a methanogenic reaction system, an aerated biogas slurry return system, an external cultivation and activity maintenance device for acid-producing bacteria, and an external cultivation and maintenance device for methanogenic bacteria. Active retention device.

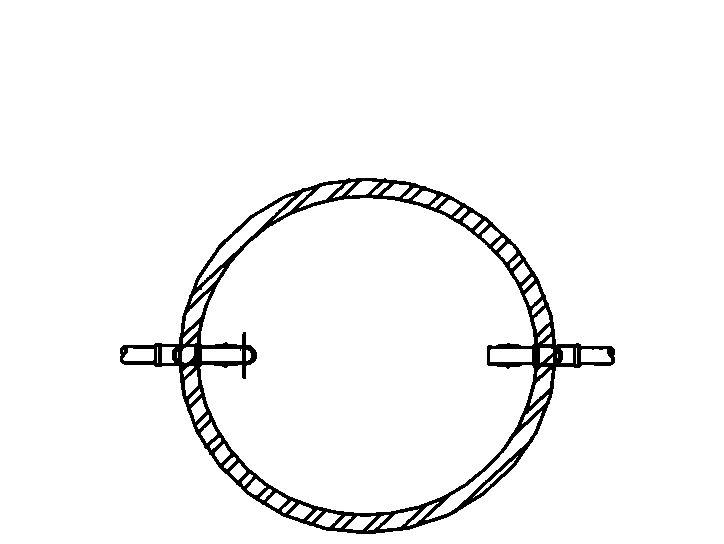

[0035] The side of the hydrolytic acidification reaction system is provided with a feed port 12 (feed inlet or discharge port), the upper part is provided with an air outlet pipe 7, and the middle part of the hydrolytic acidification reactor 5 with a stainless steel shell 17 (one or seve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com