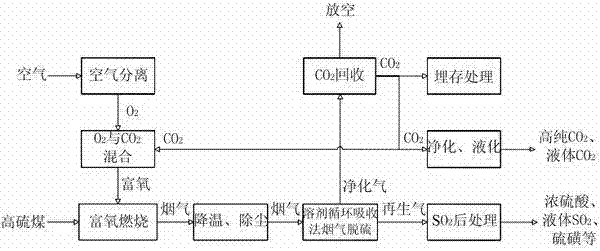

Oxygen-enriched combustion of high-sulfur coal and comprehensive flue gas treatment process

An oxygen-enriched combustion and comprehensive treatment technology, which is applied in the combustion, combustion method, combustion equipment and other directions of solid fuels, can solve the problem of comprehensive treatment and utilization of unfavorable high-sulfur coal combustion flue gas, and it is difficult to achieve clean and comprehensive utilization of high-sulfur coal. , the problem of high investment in flue gas desulfurization equipment, to achieve the effect of resource utilization, reducing coal consumption and improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The air is separated by a cryogenic air separation unit to produce O with a purity of 99.5% 2 , The O 2 CO recovered from part of the flue gas treatment stage 2 Mix to form O 2 The oxygen-enriched content is 22%. The oxygen-enriched gas is used as the combustion-supporting gas. The high-sulfur pulverized coal is oxy-fueled in the coal-fired boiler. The high-pressure steam generated after the boiler water is heated is used for power generation, and the high-sulfur coal is burned After the flue gas is cooled and dust removed, it enters the desulfurization system at 65°C. The desulfurization system uses organic amine or ionic liquid as the desulfurization solvent, and adopts the flue gas desulfurization technology of solvent circulation absorption method. The desulfurization solvent is used to remove SO in the flue gas. 2 Perform absorption removal. Absorb SO 2 The regenerating gas generated by the desulfurization solvent after heating and regeneration, its SO 2 The content i...

Embodiment 2

[0022] The air is separated by a cryogenic air separation unit to produce O with a purity of 99.5% 2 , The O 2 CO recovered from part of the flue gas treatment stage 2 Mix to form O 2 Oxygen-enriched content of 95%. The oxygen-enriched gas is used as the combustion-supporting gas. The high-sulfur pulverized coal is oxy-fueled in the coal-fired boiler. The high-pressure steam generated after the boiler water is heated is used for power generation. After the flue gas is cooled and dust removed, it enters the desulfurization system at 45°C. The desulfurization system uses organic amine or ionic liquid as the desulfurization solvent. The flue gas desulfurization technology using solvent circulation absorption method uses desulfurization solvent to remove SO in the flue gas. 2 Perform absorption removal. Absorb SO 2 The regenerating gas generated by the desulfurization solvent after heating and regeneration, its SO 2 The content is 99.5%, directly sent to the subsequent SO 2 Productio...

Embodiment 3

[0024] The air is separated by a pressure swing adsorption device to produce O with a purity of 93% 2 , The O 2 CO recovered from part of the flue gas treatment stage 2 Mix to form O 2 Oxygen-enriched content of 63%. The oxygen-enriched gas is used as the combustion-supporting gas. The high-sulfur pulverized coal is oxy-enriched in the coal-fired boiler. The high-pressure steam generated after the boiler water is heated is used for power generation, and the high-sulfur coal is burned After the flue gas is cooled and dust removed, it enters the desulfurization system at 57°C. The desulfurization system uses organic amine or ionic liquid as the desulfurization solvent, and adopts the flue gas desulfurization technology of solvent circulation absorption method. The desulfurization solvent is used to remove the SO in the flue gas. 2 Perform absorption removal. Absorb SO 2 The regenerating gas generated by the desulfurization solvent after heating and regeneration, its SO 2 The conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com