Sludge treatment device using waste heat of boiler and treatment process thereof

A technology for boiler waste heat and treatment device, which is applied in dewatering/drying/concentrating sludge treatment, incinerators, lighting and heating equipment, etc., and can solve problems such as heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

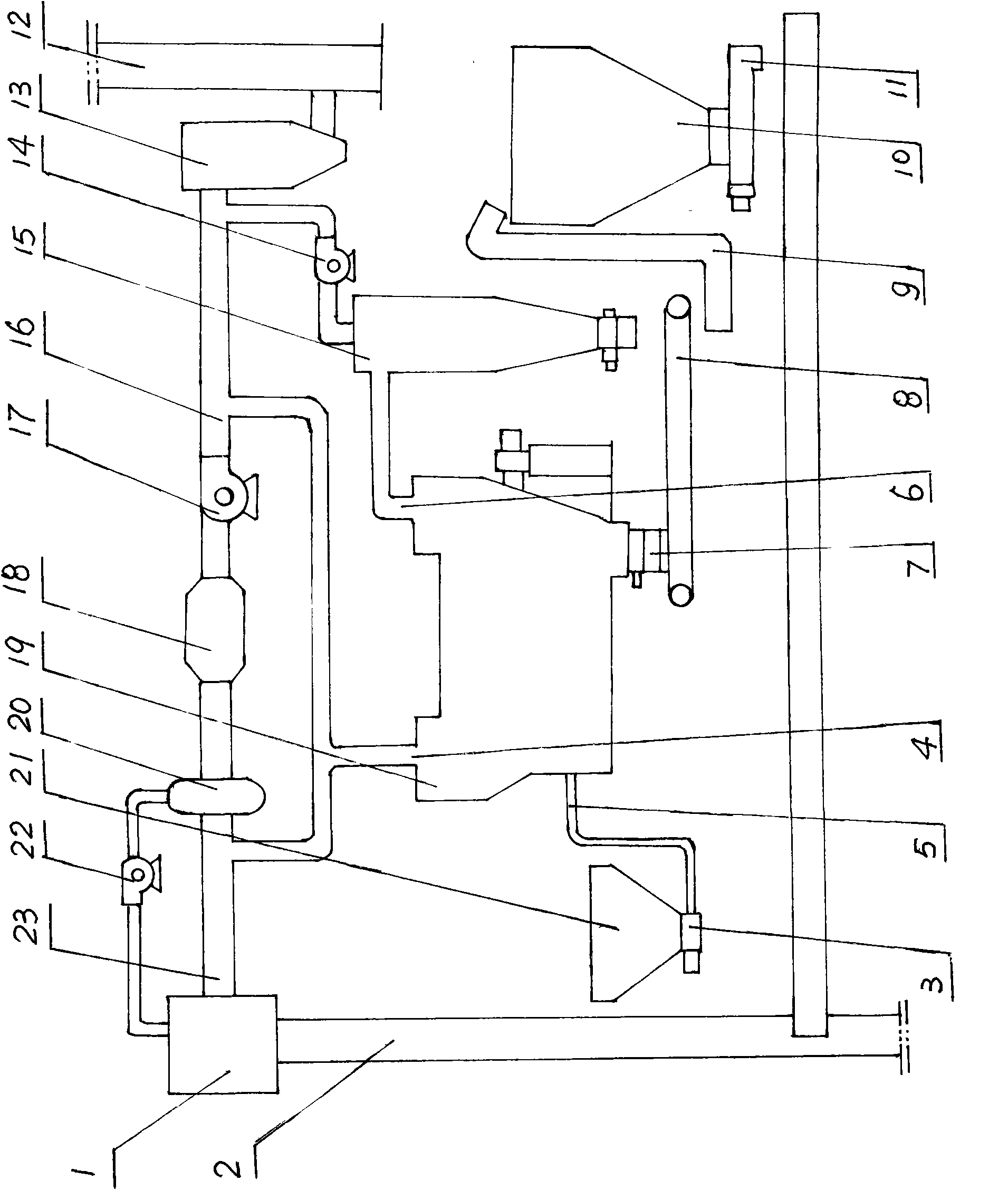

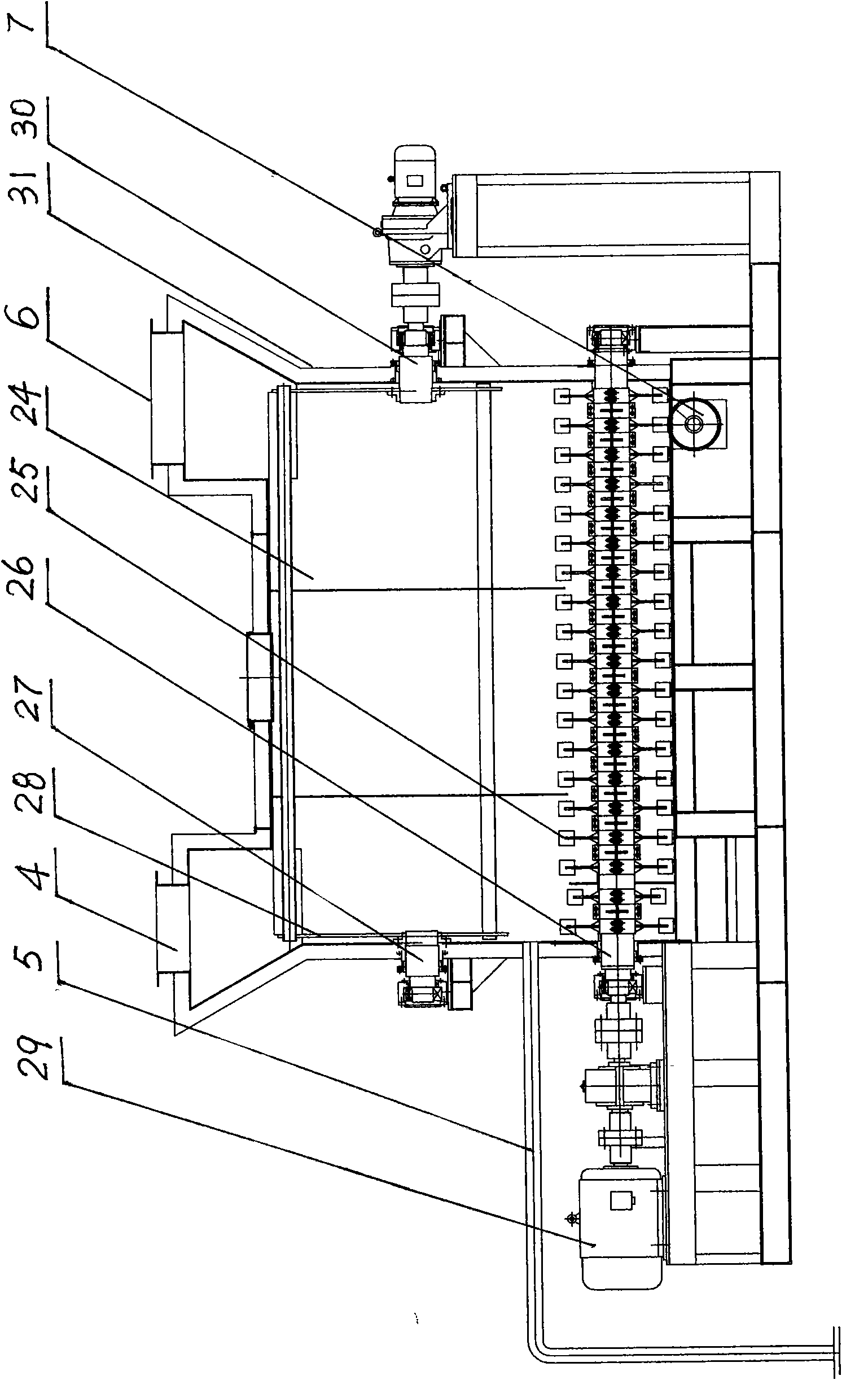

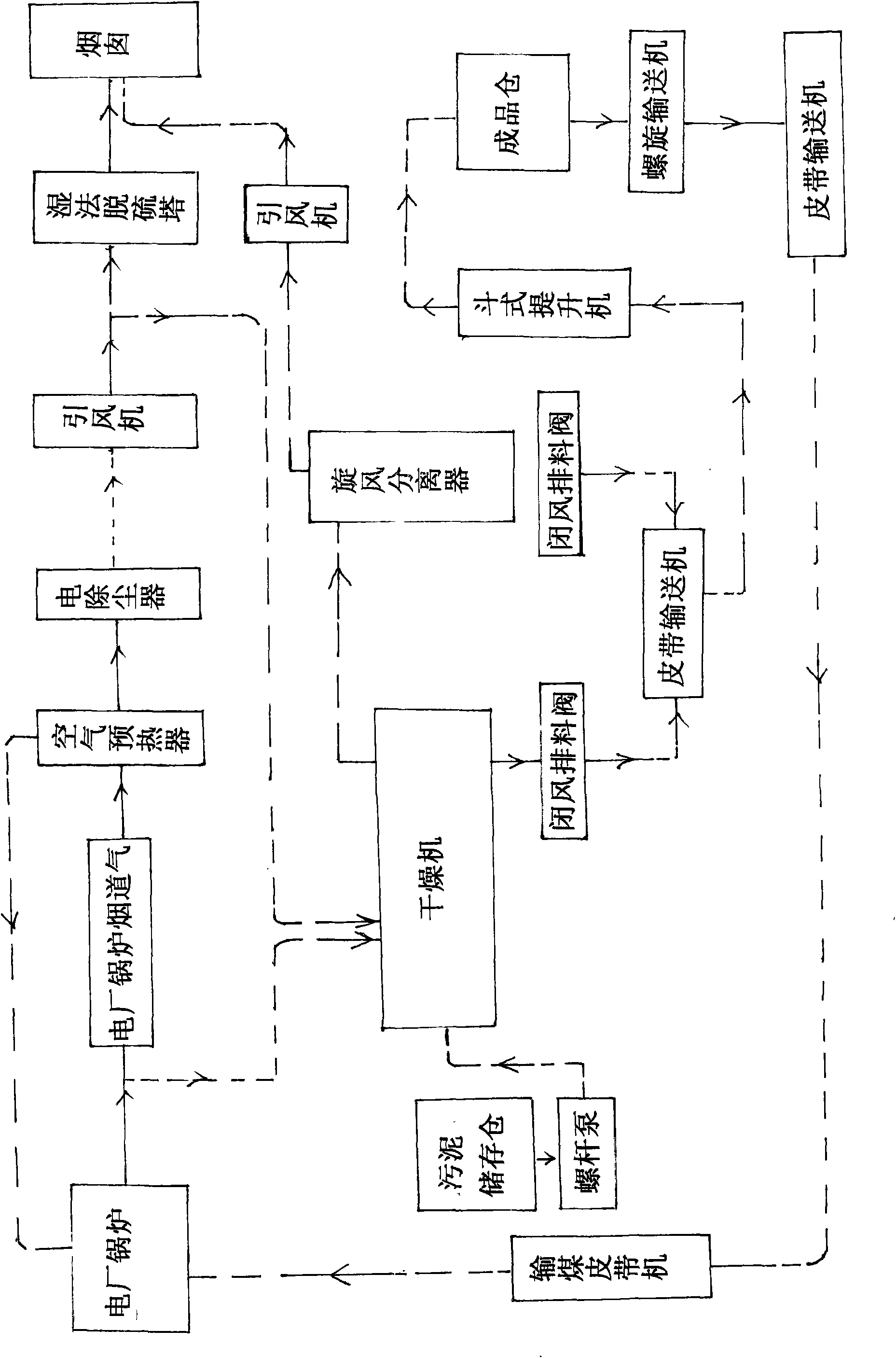

[0013] The present invention comprises boiler 1, and boiler 1 is connected with coal conveying belt device 2, smoke exhaust treatment device 16 respectively, and its structural essentials: the flue 23 of smoke exhaust treatment device 16 is connected with drier 19 and passes through induced draft fan 14, cyclone separator respectively 15 is connected with the dryer 19, the side of the dryer 19 is connected with the sludge storage bin 21, the bottom of the dryer 19 and the cyclone separator 15 are connected with the finished product bin 10 through the belt conveyor 8, and the finished bin 10 is connected through the screw conveyor 11 It is connected with the coal conveying belt device 2.

[0014] The present invention adopts following treatment process:

[0015] First, the flue gas from the flue 23 of the boiler 1 is passed into the dryer 19 to dry the sludge; after drying, the tail gas in the sludge is sent to the chimney 12, and the remaining sludge is returned to the boiler ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com