Molybdenum supported catalyst for 1-butylene disproportionation reaction and preparation method

A supported catalyst and disproportionation reaction technology, applied in physical/chemical process catalysts, molecular sieve catalysts, metathesis reaction hydrocarbon production, etc., can solve problems that do not involve mesoporous SBA-15 alumina coating or composite modification, and achieve Effect of high propylene molar yield and high reaction stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

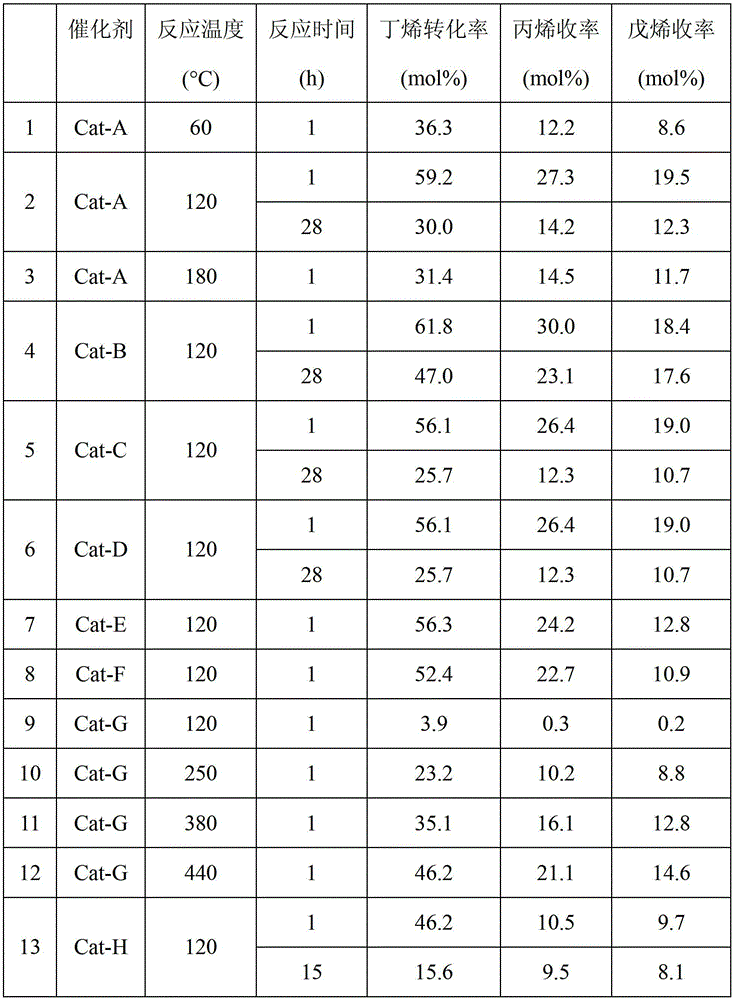

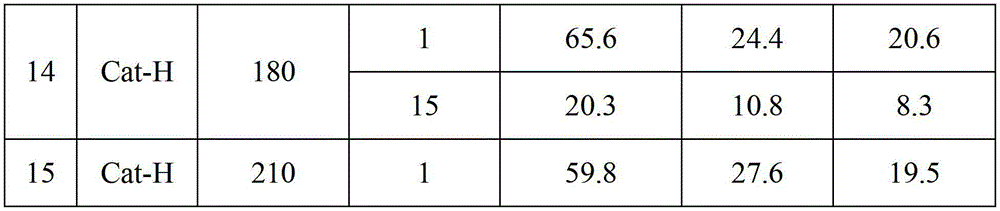

Examples

Embodiment 1

[0022] The composite carrier and catalyst were prepared by steam-induced hydrolysis. The specific steps were: weigh 3.1515g of aluminum nitrate nonahydrate and dissolve it in 10g of deionized water and stir until completely dissolved, then add 1g of mesoporous SBA-15 molecular sieve, stirred at room temperature for 0.5h. Then stir and impregnate at 60°C until the solution is completely evaporated to dryness, and then dry at 100°C for 6h. Transfer the sample to a tetrafluoroethylene beaker, place the entire tetrafluoroethylene beaker into a high-pressure reactor with a tetrafluoroethylene liner, and add 20 mL of deionized water to the space between the tetrafluoroethylene beaker and the tetrafluoroethylene liner water, sealed, and treated at 100°C for 7h. The sample was taken out from the autoclave, dried in the air at room temperature for 6 h, calcined at 100°C for 10 h, and calcined at 500°C for 6 h to finally obtain the composite carrier Support-A. Weigh 2g of the prepared...

Embodiment 2

[0024] Ammonia vapor-induced hydrolysis was used to prepare composite supports and catalysts. The specific steps were: weigh 3.1515g of aluminum nitrate nonahydrate and dissolve it in 10g of deionized water and stir until completely dissolved, then add 1g of mesoporous SBA-15 molecular sieve, stirred at room temperature for 0.5h. Then stir and impregnate at 60°C until the solution is completely evaporated to dryness, and then dry at 100°C for 6h. Transfer the sample to a tetrafluoroethylene beaker, place the entire tetrafluoroethylene beaker into a high-pressure reactor with a tetrafluoroethylene liner, and add 14wt% ammonia to the space between the tetrafluoroethylene beaker and the tetrafluoroethylene liner Aqueous solution, sealed, treated at 100°C for 7h. The sample was taken out from the autoclave, dried in the air at room temperature for 6 h, calcined at 100°C for 10 h, and calcined at 500°C for 6 h to finally obtain the composite carrier Support-B. Weigh 2g of the pre...

Embodiment 3

[0026] The composite carrier and catalyst were prepared by the traditional impregnation method. The specific steps were: weigh 3.1515g of aluminum nitrate nonahydrate and dissolve it in 10g of deionized water and stir until completely dissolved, then add 1g of template-removing mesoporous SBA-15 to the solution Molecular sieves, stirred at room temperature for 0.5h. Then it was stirred and impregnated at 60°C until the solution was completely evaporated to dryness, dried at 100°C for 6 hours, and calcined at 500°C for 6 hours to finally obtain the composite carrier Support-C. Weigh 2g of the prepared composite carrier Support-C, add 20mL of ammonium molybdate solution with a mass concentration of 0.0110g / mL, soak at room temperature for 24h, dry at 100°C, roast at 600°C for 2h, and after cooling, the obtained Mo content is 6 wt% Cat-C catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com