Polarizing film with adhesive layer and image display device

An adhesive layer, polarizing film technology, applied in the direction of adhesive type, ester copolymer adhesive, film/sheet adhesive, etc., to prevent abnormal appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

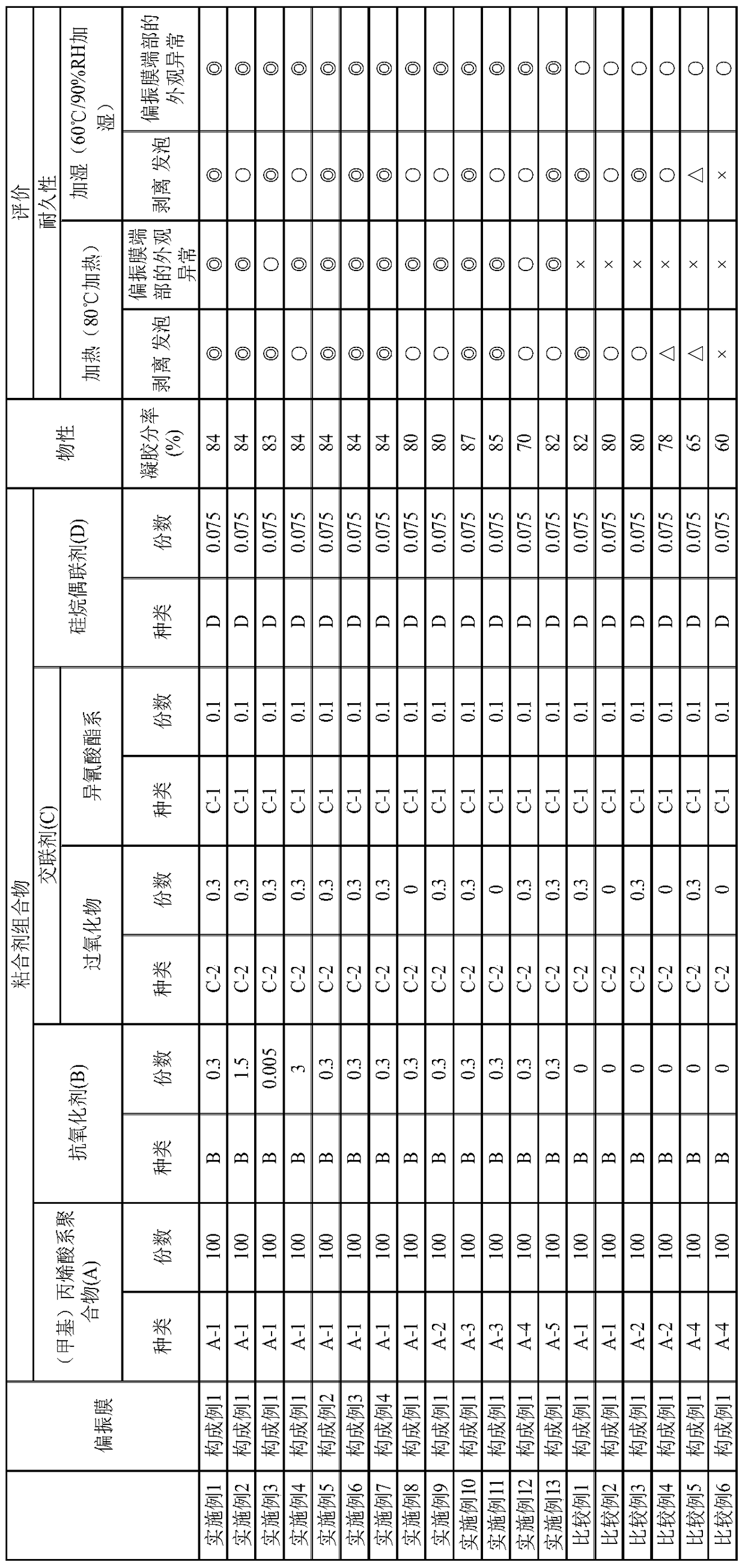

Examples

Embodiment

[0128] The following examples illustrate the present invention in detail, but the present invention is not limited by these examples. In addition, the parts and % in each example are based on weight.

[0129]

[0130] The weight-average molecular weight of the hydroxyl group-containing (meth)acrylic polymer (A) is measured by GPC (gel permeation chromatography).

[0131] ・Analyzer: HLC-8120GPC manufactured by Tosoh Corporation

[0132] ・Pillar: Made by Tosoh Corporation, G7000H XL +GMH XL +GMH XL

[0133] ・Column size: 7.8mmφ×30cm each, 90cm in total

[0134] ·Column temperature: 40℃

[0135] ·Flow: 0.8ml / min

[0136] ·Injection volume: 100μl

[0137] ·Eluent: tetrahydrofuran

[0138] Detector: Differential refractometer (RI)

[0139] ·Standard sample: polystyrene

[0140]

[0141]In order to produce a thin polarizer, first, a laminate having a 9 μm-thick PVA layer formed on an amorphous PET substrate is subjected to in-air auxiliary stretching at a stretching t...

manufacture example 1

[0151]

[0152] In a reaction vessel equipped with a condenser tube, a nitrogen gas introduction tube, a thermometer, and a stirring device, 99 parts of butyl acrylate, 1 part of 4-hydroxybutyl acrylate (HBA), and 1 part of 4-hydroxybutyl acrylate (HBA), and ) 100 parts of AIBN as an initiator was reacted at 60°C for 7 hours under a nitrogen stream, and then ethyl acetate was added to the reaction solution to obtain a hydroxyl-containing (methyl ) acrylic polymer (A-1) (solid content concentration: 30% by weight). Table 2 shows the composition and molecular weight of the (meth)acrylic polymer (A-1).

manufacture example 2

[0154]

[0155] In Production Example 1, except that a monomer mixture containing 99 parts of butyl acrylate and 1 part of 2-hydroxyethyl acrylate (HEA) was used as the monomer mixture, the weight average molecular weight was prepared in the same manner as in Production Example 1. 1.6 million solution of (meth)acrylic polymer (A-2). Table 2 shows the composition and molecular weight of the (meth)acrylic polymer (A-2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com