A kind of electrolytic processing method and processing equipment of titanium alloy slender shaft

A processing method, titanium alloy technology, applied in the direction of metal processing equipment, electrochemical processing equipment, manufacturing tools, etc., can solve problems such as difficulties, titanium alloy difficult-to-cut materials, low EDM efficiency, etc., to achieve production efficiency and guarantee Accuracy, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Configure the non-aqueous electrolyte required for the electrolytic processing of titanium alloys: weigh 0.9 kg of ammonium bifluoride and 0.5 kg of ammonium chloride powder, and mix them evenly. Weigh 8.6 kg of formamide solvent, pour the above mixed powder into an electrolytic cell filled with formamide solvent, fully stir the powder in the electrolytic cell until the powder is completely dissolved, and obtain an electrolyte.

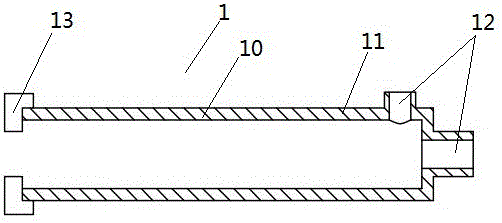

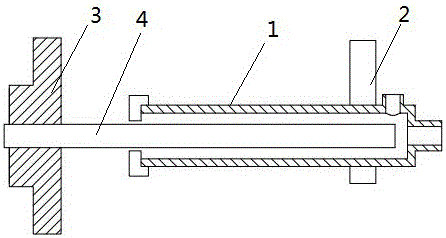

[0023] 2) Install the titanium alloy workpiece 4 and the copper tube cathode 1: clamp the titanium alloy workpiece 4 on the triangular chuck 3 of the professional electrolytic turning machine tool, fix the copper tube cathode 1 by the cathode clamping tool 2; move the copper tube cathode 1 Make the titanium alloy workpiece 4 to be processed penetrate into the copper tube cathode 1, and by adjusting the mutual position, ensure that the titanium alloy workpiece 4 and the copper tube cathode 1 are insulated from each other, and the radial gap be...

Embodiment 2

[0031]1) Configure the non-aqueous electrolyte required for electrolytic processing of titanium alloys: weigh 0.5 kg of ammonium bifluoride and 0.2 kg of ammonium chloride powder, and mix them evenly. Weigh 9.3 kg of formamide solvent, pour the above mixed powder into an electrolytic cell filled with formamide solvent, fully stir the powder in the electrolytic cell until the powder is completely dissolved, and obtain an electrolyte.

[0032] 2) Install the titanium alloy workpiece 4 and the copper tube cathode 1: clamp the titanium alloy workpiece 4 on the triangular chuck 3 of the professional electrolytic turning machine tool, fix the copper tube cathode 1 by the cathode clamping tool 2; move the copper tube cathode 1 Make the titanium alloy workpiece 4 to be processed penetrate into the copper tube cathode 1, and by adjusting the mutual position, ensure that the titanium alloy workpiece 4 and the copper tube cathode 1 are insulated from each other, and the radial gap between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com