Ladle breathable upper nozzle seat brick and method for controlling nozzle slag entrainment

A nozzle block and ladle technology, which is applied in the direction of manufacturing tools, casting molten material containers, metal processing equipment, etc., can solve the unsolved technical problems of eddy current slag rolling in the upper nozzle of the ladle, unreasonable design of the cavity shape of the tapping nozzle block, Can not suppress the problem of slag entanglement at the nozzle of the molten steel tank, and achieve the effect of promoting floating and removal, solving eddy current slag entanglement, and convenient and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

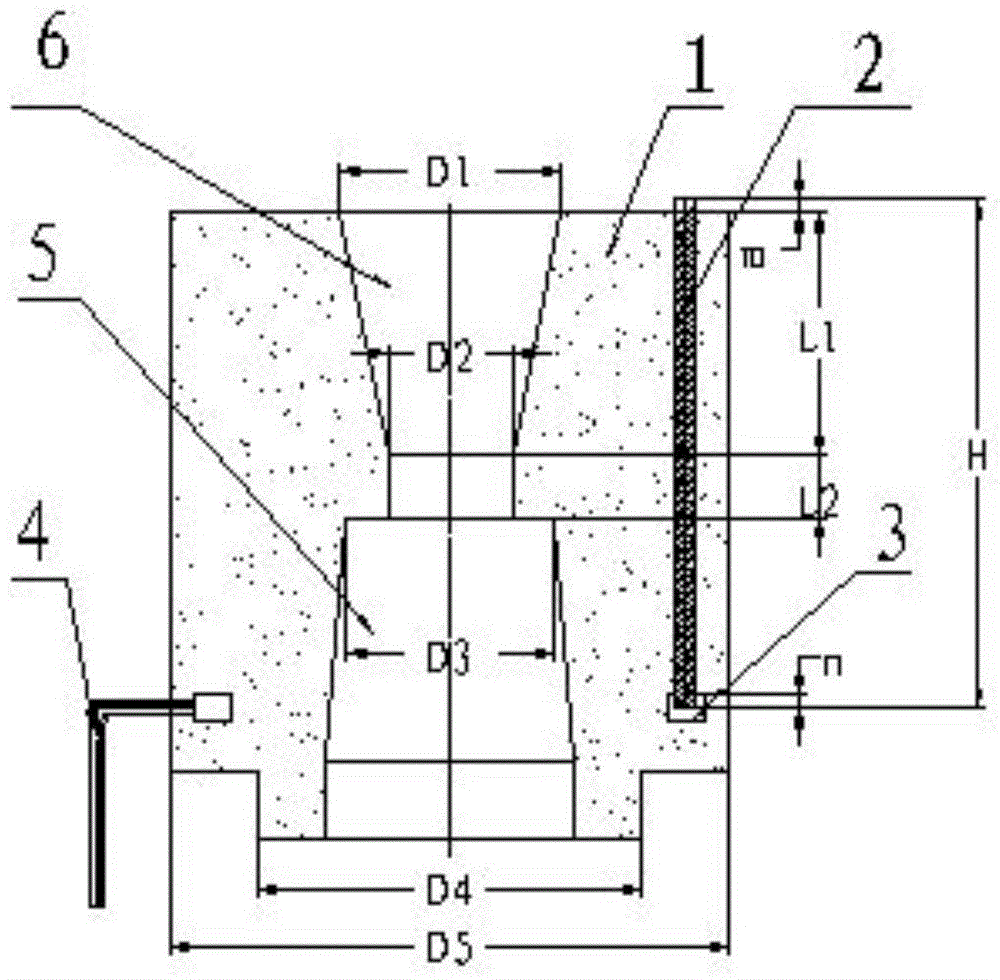

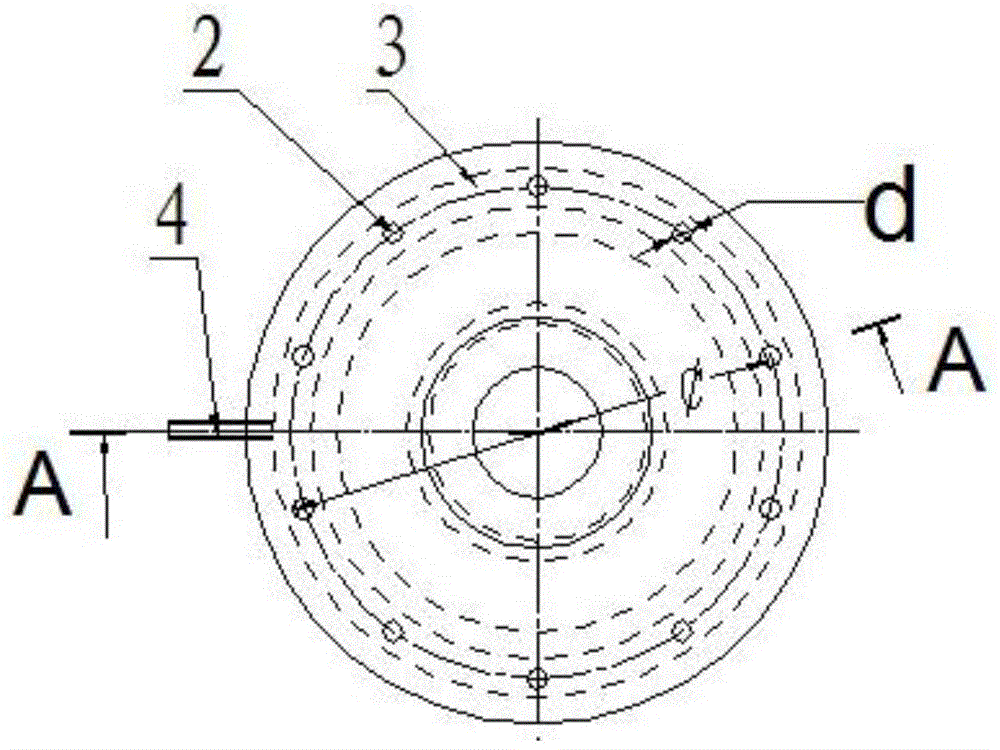

[0040] A kind of ladle breathable upper nozzle seat brick, such as Figure 1-Figure 4 As shown, it includes a ladle nozzle block body 1, a gas-permeable ceramic rod 2, an air chamber box 3. The ladle nozzle block body is provided with a flow steel hole 6, a nozzle mounting hole 5, and a ladle nozzle block from top to bottom. The brick body includes an integrally formed upper boss and a lower boss. The outer diameter of the lower boss is smaller than that of the upper boss. The upper boss of the ladle upper nozzle base brick body 1 has a cylindrical shape, and the lower boss has a cylindrical shape. The outer diameter D4 of the lower boss is smaller than the outer diameter D5 of the upper boss, the outer diameter D5 of the upper boss is 420mm, and the outer diameter D4 of the lower boss is 320mm. The air-permeable ceramic rod 2 and the air chamber box 3 are both set in the upper boss of the upper nozzle block body 1 of the ladle. The air chamber box 3 is located at the bottom of...

Embodiment 2

[0046] The ladle air-permeable upper nozzle block as described in Example 1, the difference is:

[0047] The outer diameter D5 of the upper boss of the ladle upper nozzle base brick body 1 is 480mm, and the outer diameter D4 of the lower boss is 360mm. The diameter d of the air-permeable ceramic rod 2 is 12mm, the height of the air-permeable ceramic rod is greater than the height of the flow steel hole and less than the height of the boss on the brick body of the ladle upper nozzle, and the height H of the air-permeable ceramic rod is 320mm. There are 16 air-permeable ceramic rods 2, which are uniformly arranged in the upper nozzle block body in a ring shape around the flow steel hole, and the diameter of the ring is 400mm. The top end of the air-permeable ceramic rod 2 protrudes from the upper surface of the upper nozzle base brick body to a height m of 10mm. The air chamber box is provided with 16 slots for fixing the air-permeable ceramic rod. The shape and position of the slo...

Embodiment 3

[0051] The ladle air-permeable upper nozzle block as described in Example 1, the difference is:

[0052] The outer diameter D5 of the upper boss of the ladle upper nozzle base brick body 1 is 460mm, and the outer diameter D4 of the lower boss is 340mm. The diameter d of the air-permeable ceramic rod 2 is 18mm. The height of the air-permeable ceramic rod is greater than the height of the flow steel hole and less than the height of the boss on the brick body of the ladle upper nozzle. The height of the air-permeable ceramic rod H is 360mm. There are 12 air-permeable ceramic rods, which are uniformly arranged in the upper nozzle base brick body in a ring shape around the flow steel hole. The diameter of the ring is 360mm. The height m of the top end of the ventilating ceramic rod 2 protruding from the upper surface of the upper nozzle block body is 6mm. The air chamber box is provided with 12 slots for fixing the ventilating ceramic rods. The shape and position of the slots correspo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com