A vacuum coating production line

A vacuum coating and production line technology, applied in vacuum evaporation coating, sputtering coating, ion implantation coating, etc., can solve the problems of inaccurate reception of substrate signals, increased gate thickness, elimination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0208] The present invention will be further described in detail and completely below in conjunction with the embodiments and the accompanying drawings.

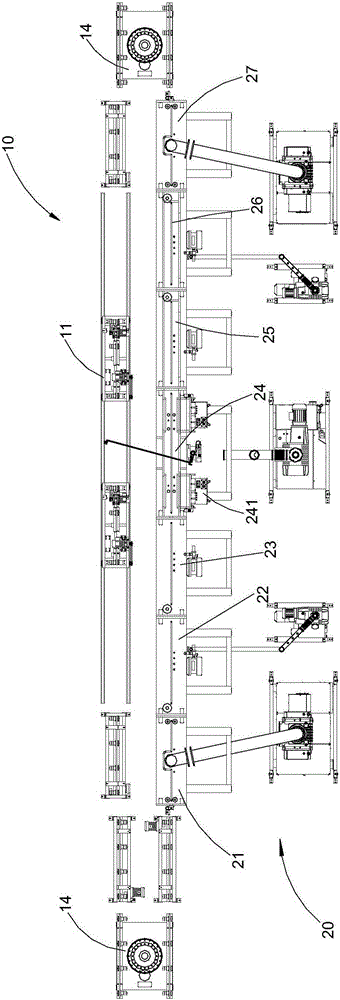

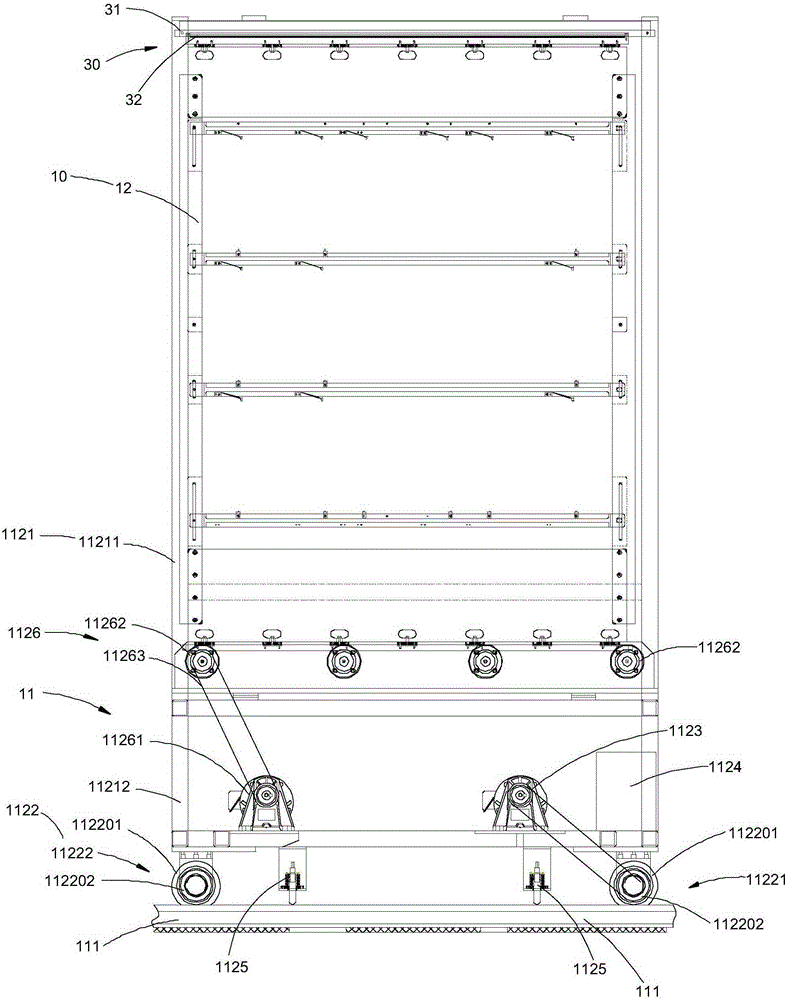

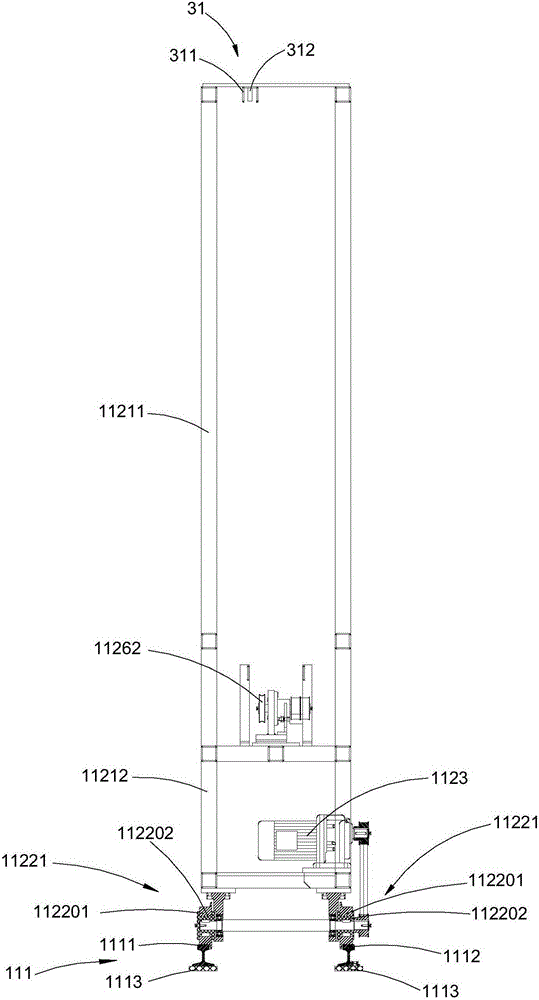

[0209] Figure 1 to Figure 29 , is a schematic diagram of a preferred embodiment of the vacuum coating production line provided by the present invention. Such as figure 1 As shown, the coating production line includes a transfer line 10 and a coating line 20, and the transfer line 10 is connected to the coating line 20. In order to save floor space and improve work efficiency, the transfer line 10 and the coating line 20 are arranged in parallel.

[0210]The coating line 20 comprises an inlet chamber 21, an inlet transition chamber 22, an inlet buffer chamber 23, a coating chamber 24, an outlet buffer chamber 25, an outlet transition chamber 26 and an outlet chamber 27, an inlet chamber 21, an inlet transition chamber The chamber 22, the inlet buffer chamber 23, the coating chamber 24, the outlet buffer chamber 25, the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com