WS2/Zr soft coating micro-nano composite texture ceramic cutting tool and preparing method thereof

A ceramic tool and micro-nano composite technology, which is applied in coatings, tools for lathes, metal material coating technology, etc., can solve problems such as extremely severe friction and tool wear, achieve low friction coefficient, reduce contact length, The effect of improving cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

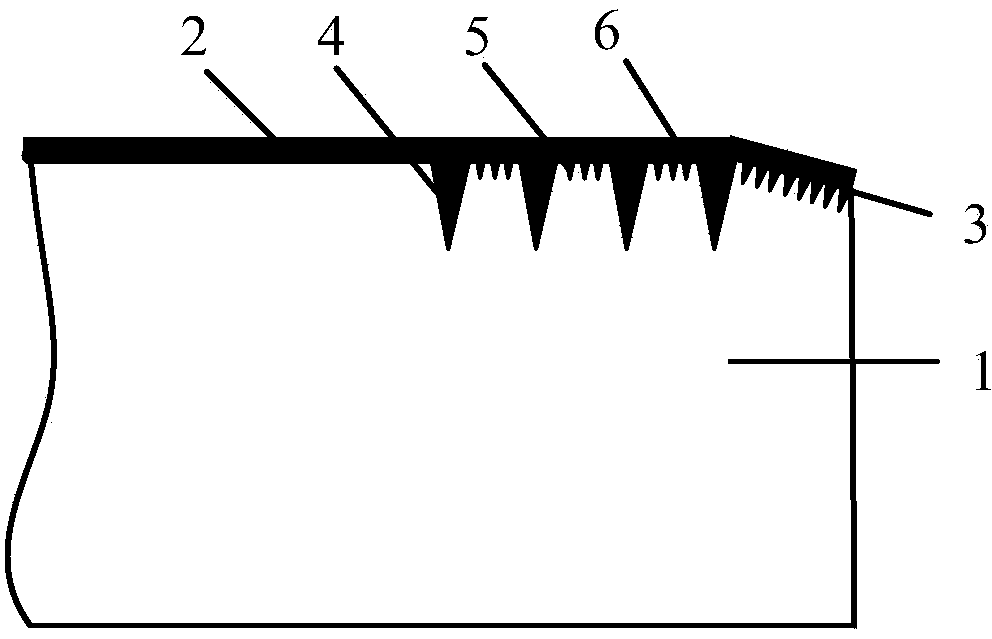

[0020] Example 1: A WS 2 / Zr soft coating micro-nano composite texture ceramic tool and preparation method thereof, matrix material is Al 2 o 3 Base ceramics; the negative chamfer of the ceramic tool of the present invention has a nano-texture, the rake face has a micro-nano composite texture, and the surface of the texture is deposited with WS 2 / Zr soft coating, there is a Zr transition layer between the soft coating and the texture. The preparation method of the cutting tool uses a solid-state laser to process a micron texture on the rake face of a ceramic tool, and uses a femtosecond laser to process a nano-texture on the negative chamfer and rake face of a ceramic tool, and then uses multi-arc ion plating+ The intermediate frequency magnetron sputtering deposition method successively deposited a layer of Zr transition layer and WS on the surface of the textured ceramic tool 2 / Zr soft coating, its concrete preparation method is as follows:

[0021] (1) Machining micro...

example 2

[0031] Example 2: A WS2 / Zr soft coating micro-nano composite texture ceramic tool and its preparation method, the matrix material is Si 3 N 4 Base ceramics; the negative chamfer of the ceramic tool of the present invention has a nano-texture, the rake face has a micro-nano composite texture, and the surface of the texture is deposited with WS 2 / Zr soft coating, there is a Zr transition layer between the soft coating and the texture. The preparation method of the cutting tool is to use solid-state laser to process micron texture on the rake face of ceramic tool, and use femtosecond laser to process nano-texture on the negative chamfer and rake face of ceramic tool, and then use multi-arc ion plating+ The intermediate frequency magnetron sputtering deposition method successively deposited a layer of Zr transition layer and WS on the surface of the textured ceramic tool 2 / Zr soft coating, its concrete preparation method is as follows:

[0032] (1) Processing micro-nano textu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com