Method for producing antimicrobial peptide through fermentation of brevibacillus laterosporu

A Brevibacillus and antibacterial peptide technology, applied in microorganism-based methods, biochemical equipment and methods, fermentation and other directions, can solve the problems of large influence of pH value of fermentation broth, unsuitable for industrial production, complex production process, etc., and achieve antibacterial Wide spectrum, easy to promote, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 Utilizes the technology of Brevibacillus lateralsporosa fermentation to produce antimicrobial peptide

[0030] The specific process is as follows:

[0031] 1. Seed cultivation

[0032] Put the glycerol tube containing B.laterosporu AS1.2827 into the sterilized NB culture medium at 32°C for 24 hours; then insert it into the NB medium at 5v / v% inoculum size and culture at 32°C for 8 hours to obtain the bacterial concentration for 10 7 cfu / mL of the secondary seed solution.

[0033] 2. 5L fermenter culture

[0034] Put the secondary seed liquid obtained in step 1 into a 5L fermenter equipped with 3L fermentation medium at a 5v / v% inoculation amount, at 32°C, 300r / min, and under the conditions of ventilation 1:0.5v / v / min Cultivate for 15h.

[0035] Among them, fermentation medium (w / v): glycerin 2.0%, soybean meal powder 2.0%, CaCl 2 0.005%, Tween-200.5%, adjusted to pH 7.2, prepared with water.

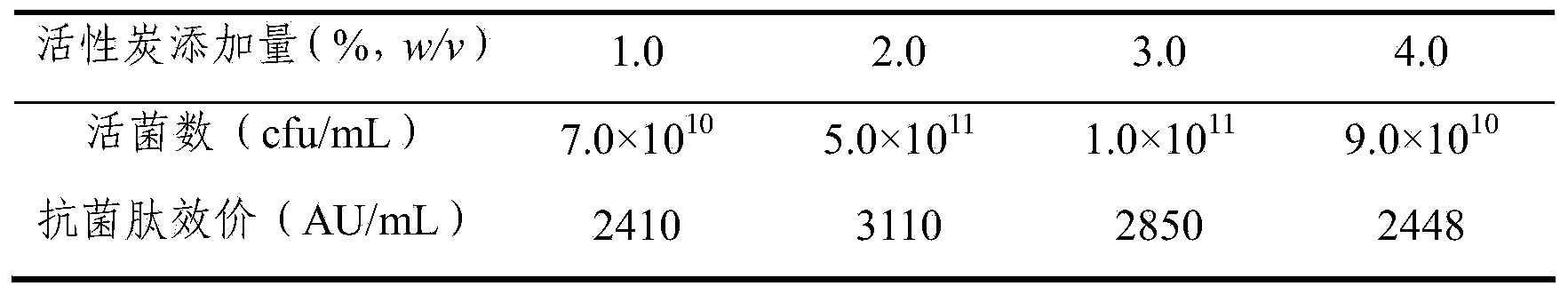

[0036] 3. Add activated carbon adsorption separation coup...

Embodiment 2

[0040] Embodiment 2 Utilizes the technique of Brevibacillus lateralsporosa fermentation to produce antimicrobial peptide

[0041] The specific process is as follows:

[0042] 1. Seed cultivation

[0043] Put the slant of preserved B.Laterosporu AS1.2738 into the sterilized NB medium, 34°C, culture time 24h, then insert 3v / v% inoculation amount into the NB seed medium, culture at 34°C for 12h, and obtain the bacterial concentration for 10 8 cfu / mL of the secondary seed solution.

[0044] 2. Fermentation tank culture

[0045] The secondary seed liquid obtained in step 1 was inserted into a 5L fermenter equipped with 4L fermentation medium according to the inoculum amount of 8v / v% to carry out fermentation culture.

[0046] Fermentation medium (w / v): 1.5% soluble starch, 1.5% yeast powder, CaCl 2 0.15%, ZnCl 2 0.008%, MnCl 2 0.05%, Tween-202.0%, pH7.0, prepared with water.

[0047] Fermentation conditions: temperature 34°C, ventilation rate 1:0.5v / v / min, dissolved oxygen ...

Embodiment 3

[0051] The impact of embodiment 3 activated carbon addition time on viable count and antimicrobial peptide output

[0052] Using Brevibacillus lateralosporu (B.laterosporu) AS1.864 as the fermentation strain, first put the glycerol tube of the preserved strain into the sterilized NB medium, culture it at 32°C for 24 hours, and insert it into NB according to the inoculation amount of 3v / v%. Culture medium, cultivated at 32°C for 12h, and obtained a bacterial concentration of 10 8 cfu / mL of the secondary seed solution.

[0053] A 5L fermenter was used, and the inoculation amount of 5v / v% was inserted into the system equipped with 3L fermentation medium, and the fermentation was carried out at 32°C, the ventilation rate was 1:0.5v / v / min, and the rotation speed was 300r / min. At the 12th, 16th, 20th, and 24th hours of fermentation, add 2% powdered activated carbon and 2v / v% concentrated material medium, and continue to ferment for another 24 hours; with no activated carbon as a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com